This page describes how to cut all these slots

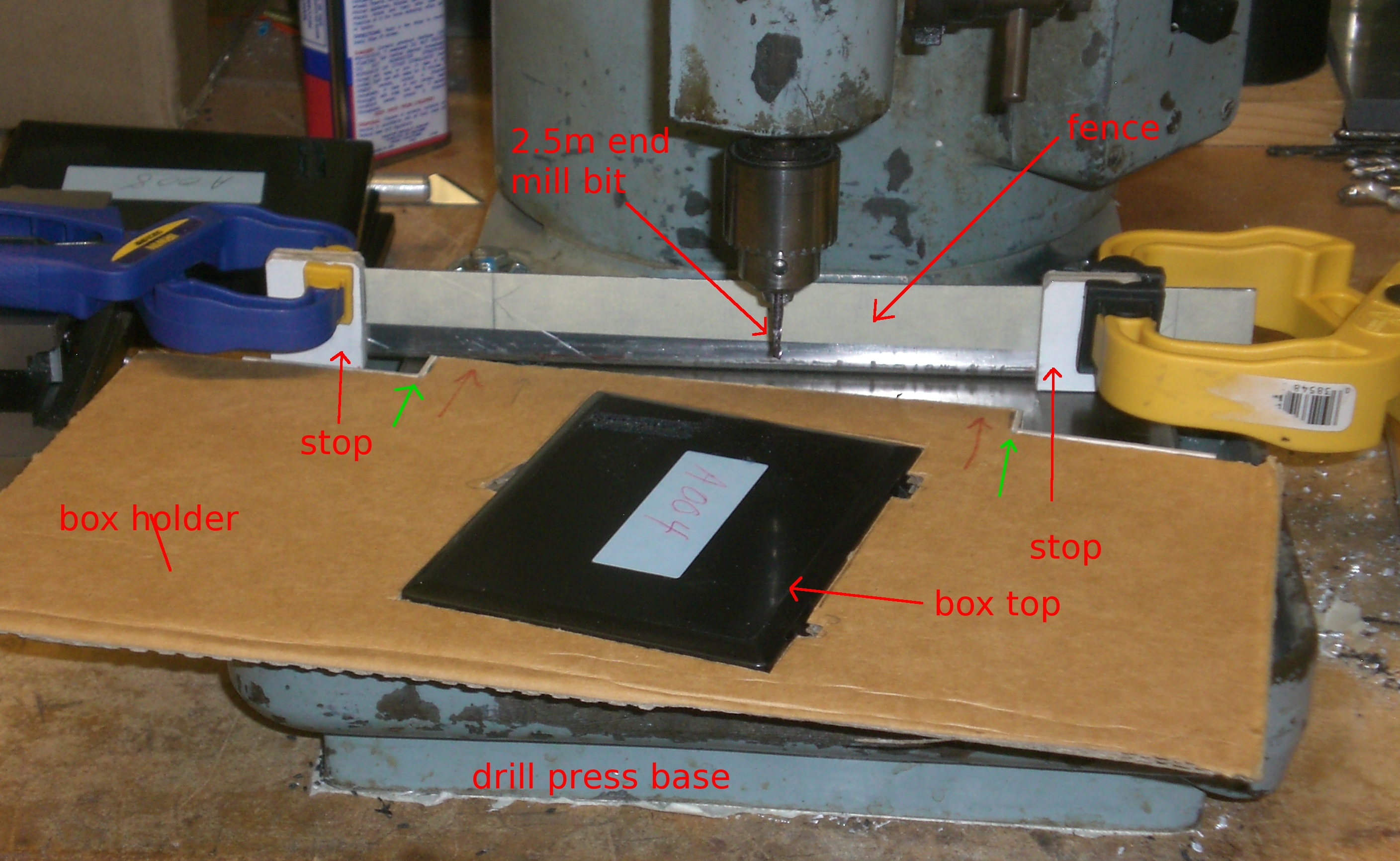

In the drill press base, there were 4 unthreaded holes. I glued T-nuts into the bottom of these holes, which take 1/4" threaded posts. I folded an Al strip and cut slots in it so that it makes a fence that mounts on the posts with wing nuts, and is adjustable.

In the picture, the fence is indicated, with two stops clamped onto it.

The cardboard holder has a space cut out so that it fits tightly over a box top. It holds it at an angle, slides against the fence and stops at the fence stops such that you can accurately cut one long edge of one of the slots repeatedly. After setup, you can process 2-3 tops per minute. Then you move the fence and cut the other long end of the slot. Next, you move the fence and mount it along the right-hand side of the base, and cut the short ends of the slots.

There are 3 different cardboard holders which which you can make all the cuts. For some cuts, you have to flip over the cardboard, or put the top in upside down.

Once we get the big boxes in, we can cut make cardboard holders for the big tops, and machine all of them quickly.

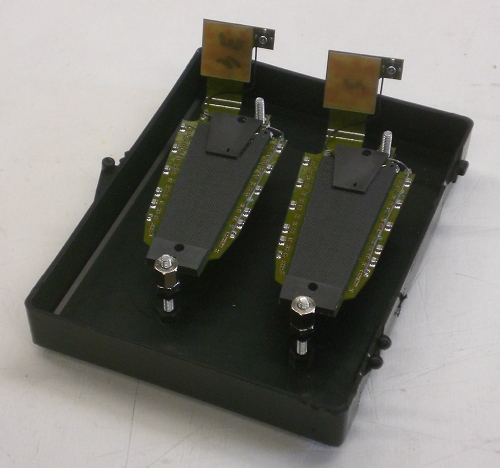

Bigger →