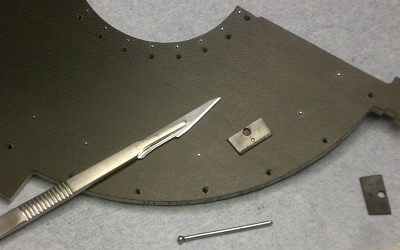

If there is a glue shoulder, use the tip of the scalpel to clean all around the base of the pin. Repeat the test until the pedestal no longer tips when touched.

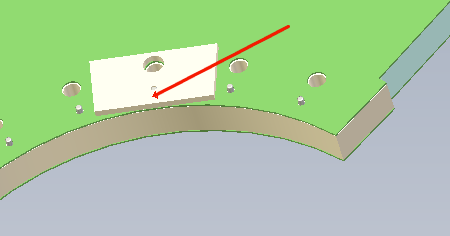

When you have checked all 24 pins on a side, take a fresh small pedestal and repeat the procedure for all pins. Graphite is very soft, and the first pedestal may have worn during the first round. I marked the used pedesals with an 'X'. Repeat on the other side of the disk.

Bigger →