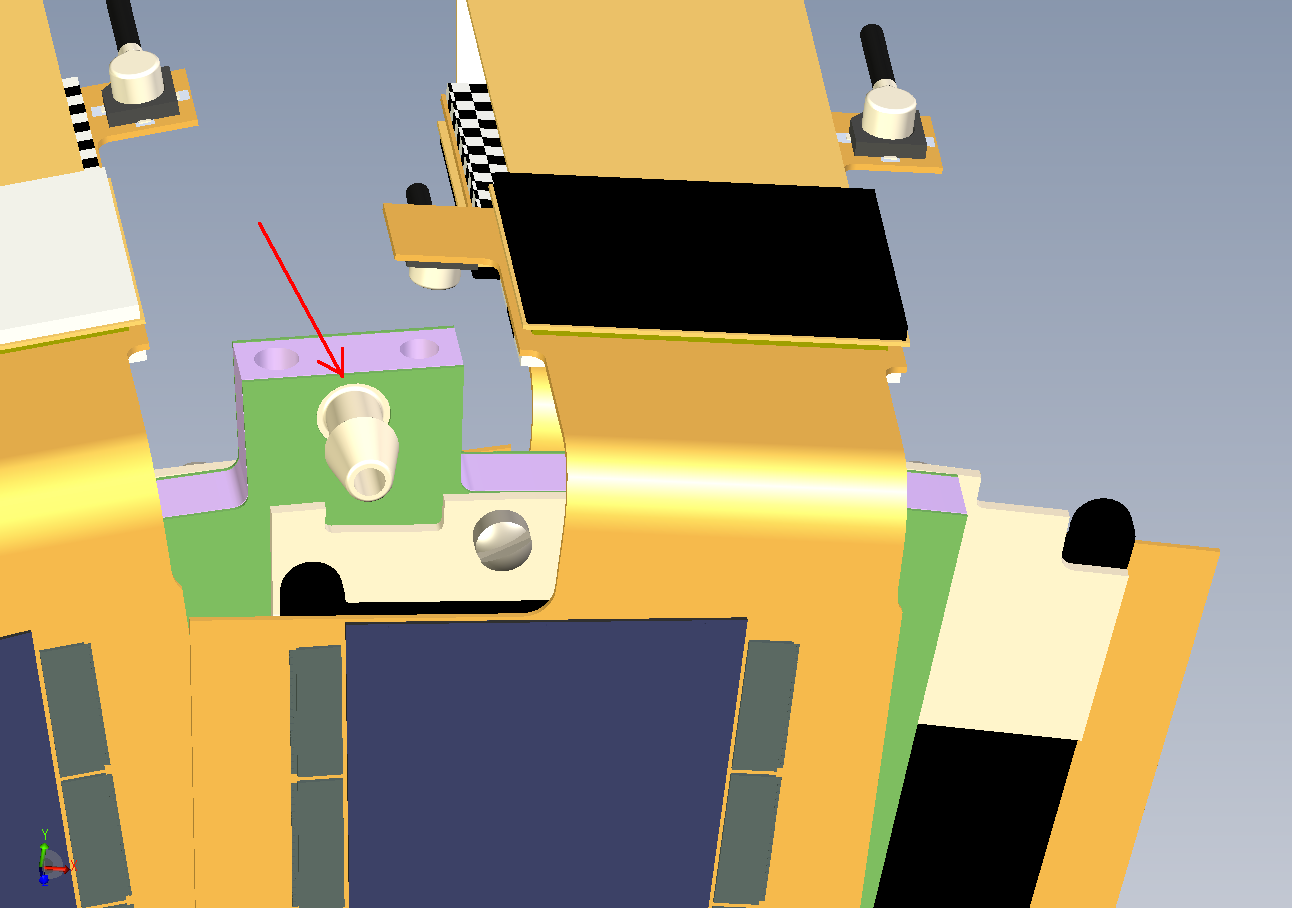

| There is concern about the strength of the glue joint between the

peek core material of the half-disk edge,

and the surface carbon sheet, in the vicinity of the hose barb. If

coolant leaks

would occur, this would be the weakest spot.

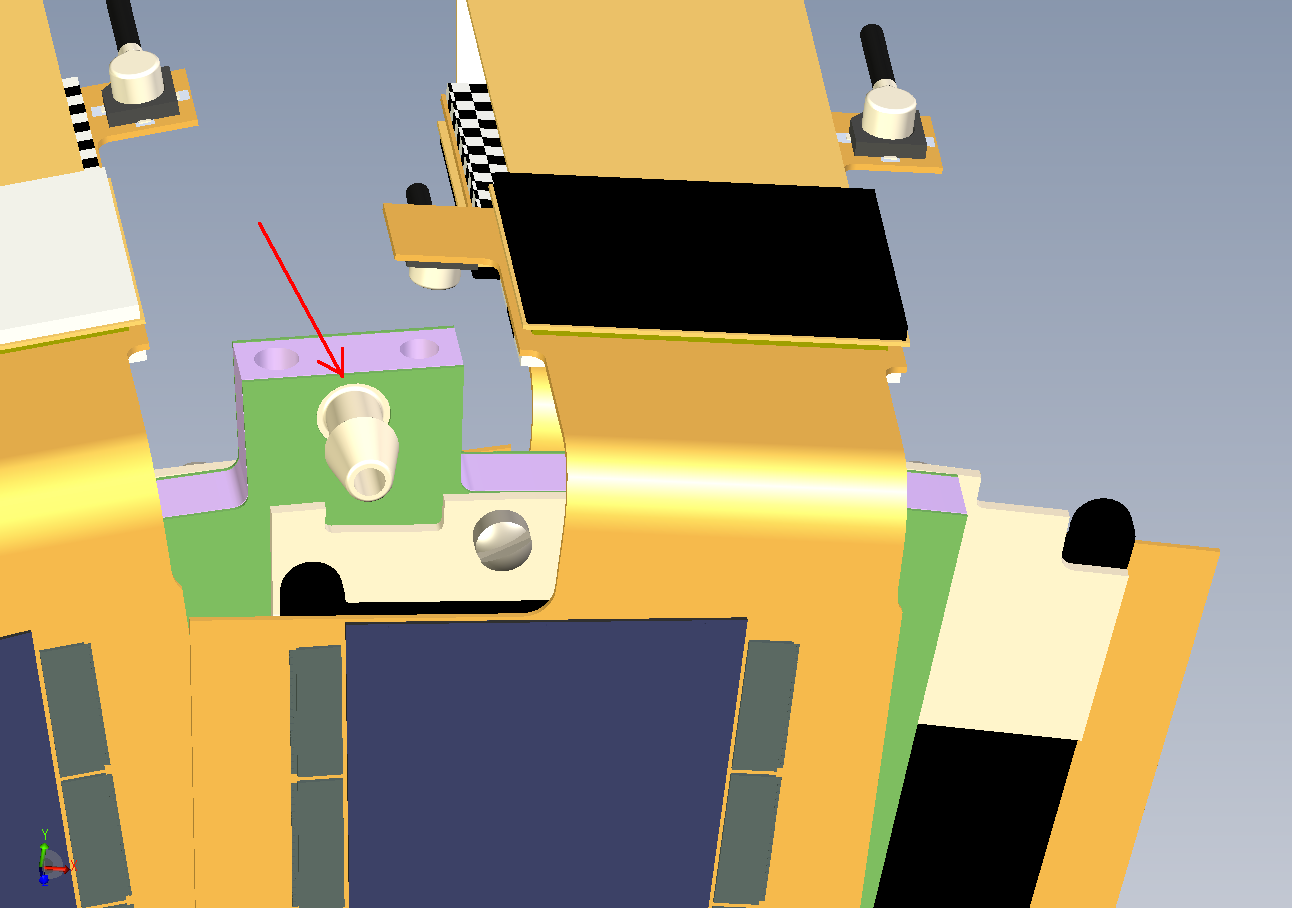

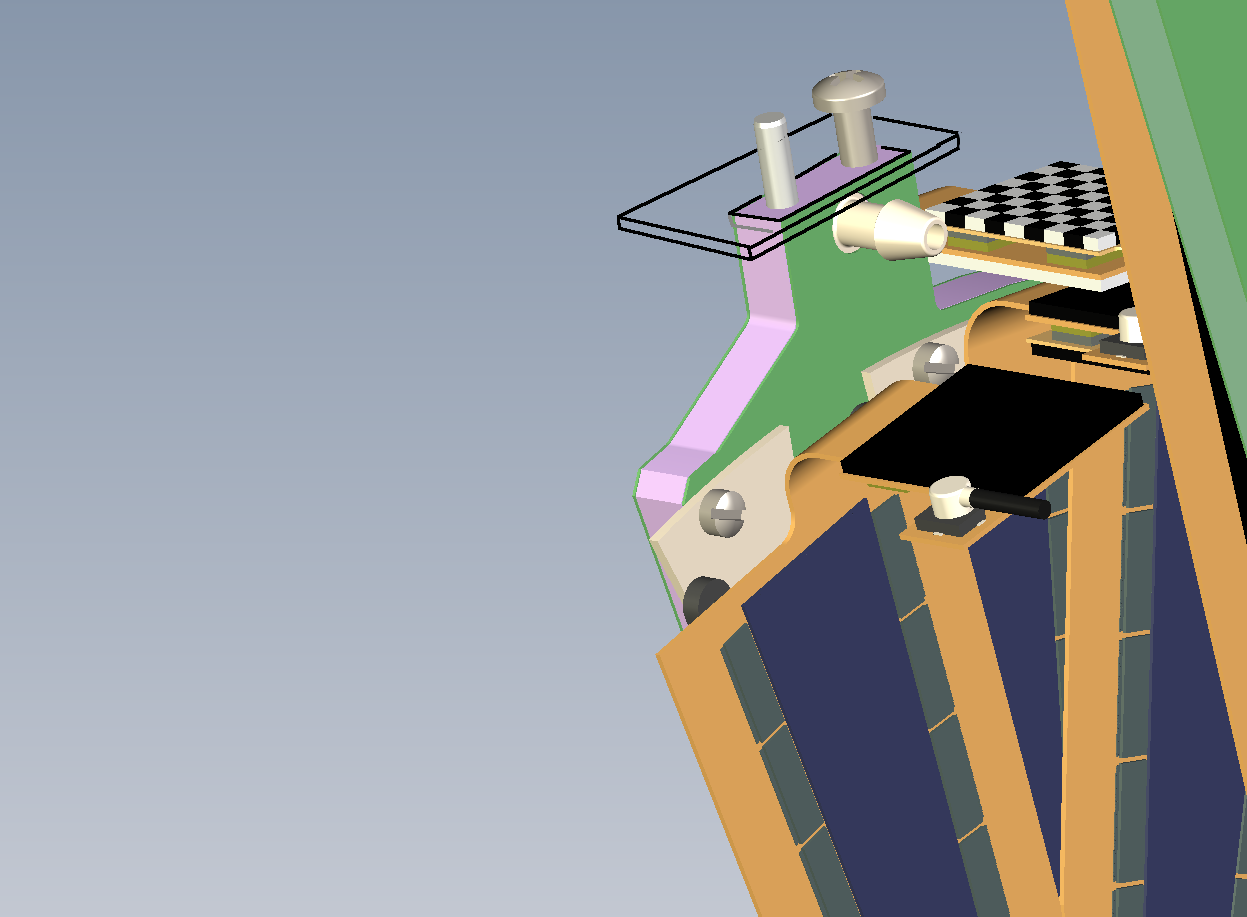

The vicinity of the mounting tabs on the disk side is

relatively unobstructed by HDIs and extension cables. Shown here

is the top tab of station 3.

The two holes in the top of the tab are where the mounting

pins/screws go.

|

|

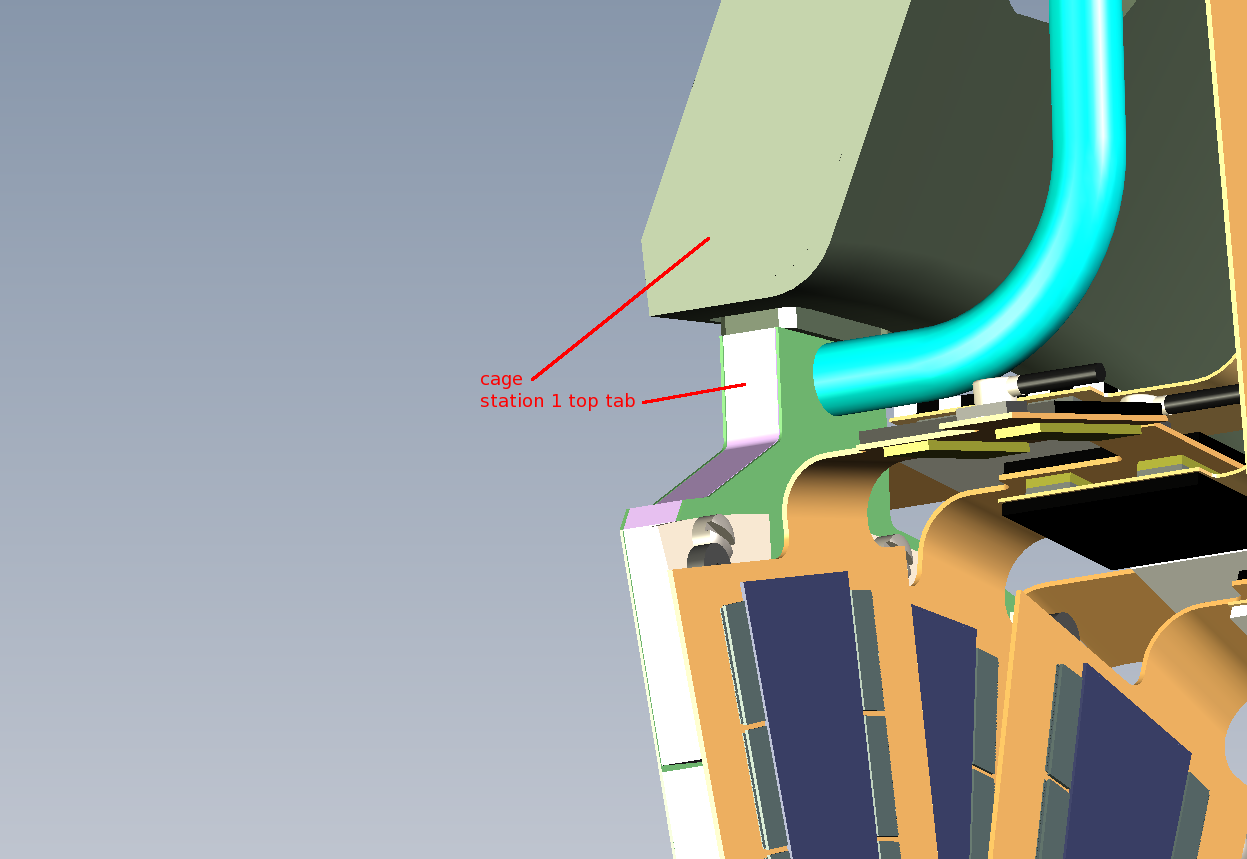

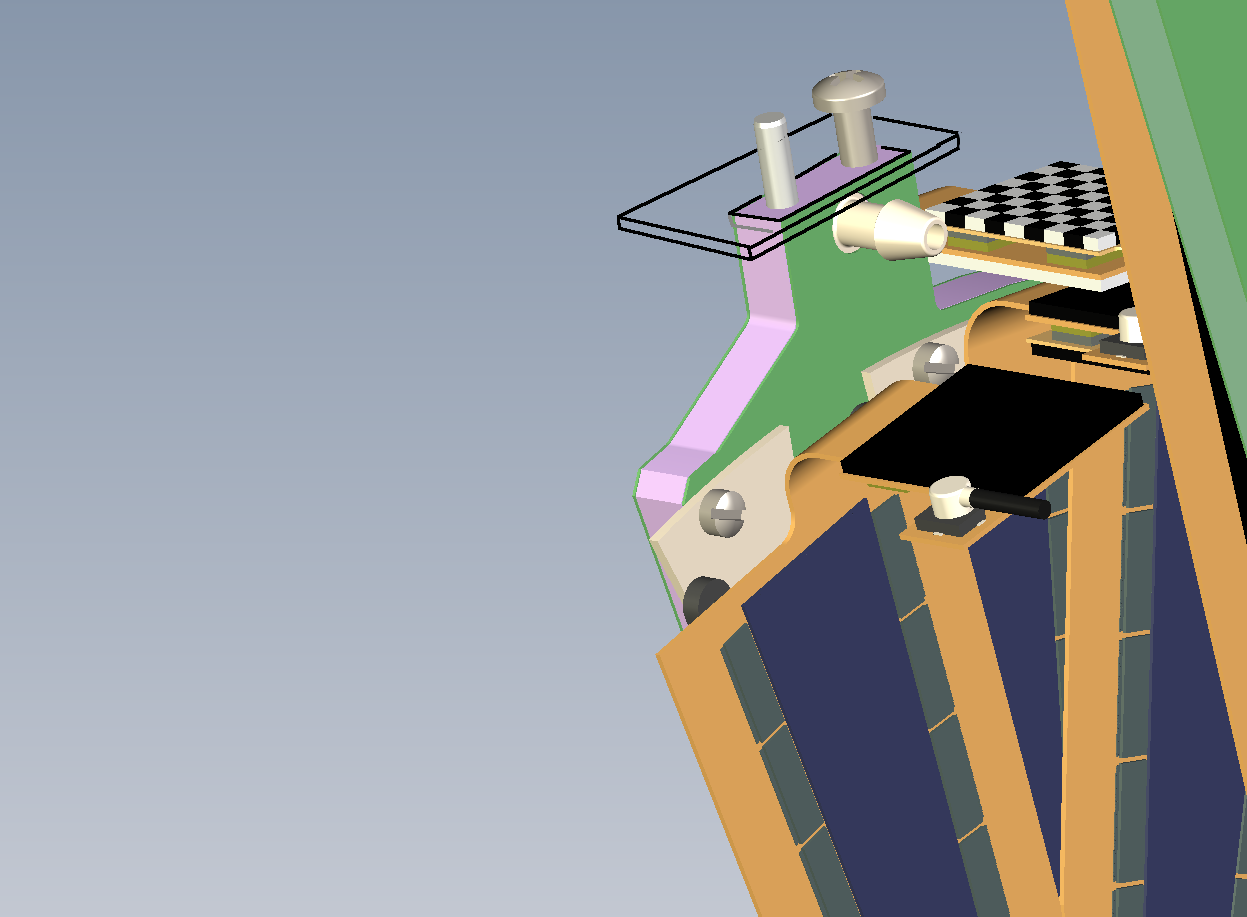

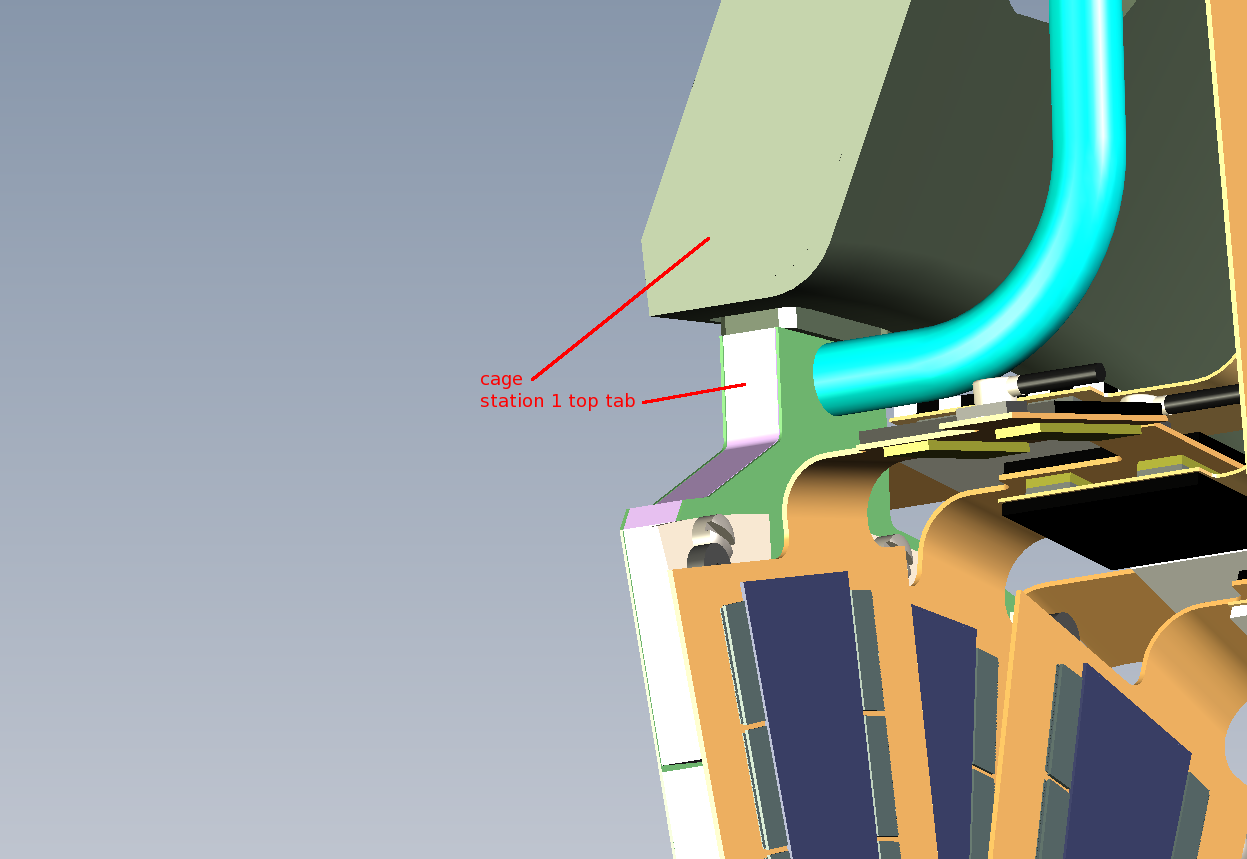

| The way the disks meet the cage, there is no way to put a clamp

over the top of the tab, since it would be in between the

tab and the cage. This is the top of station 1.

|

|

| In this view of the same area, the cage has been made invisible.

There is not a lot of space for a clamp, which I drew in black,

that wraps around the top as shown.

The thickness is limited to where it touches the barb (1.22 mm),

though you could make it thicker and file out a notch for the barb).

The width (z) here pushes the hose out a little,

(1/3 of the distance to the barb is 1.41 mm).

On the sides and the front the clamping plate can be a little wider.

|

|

|

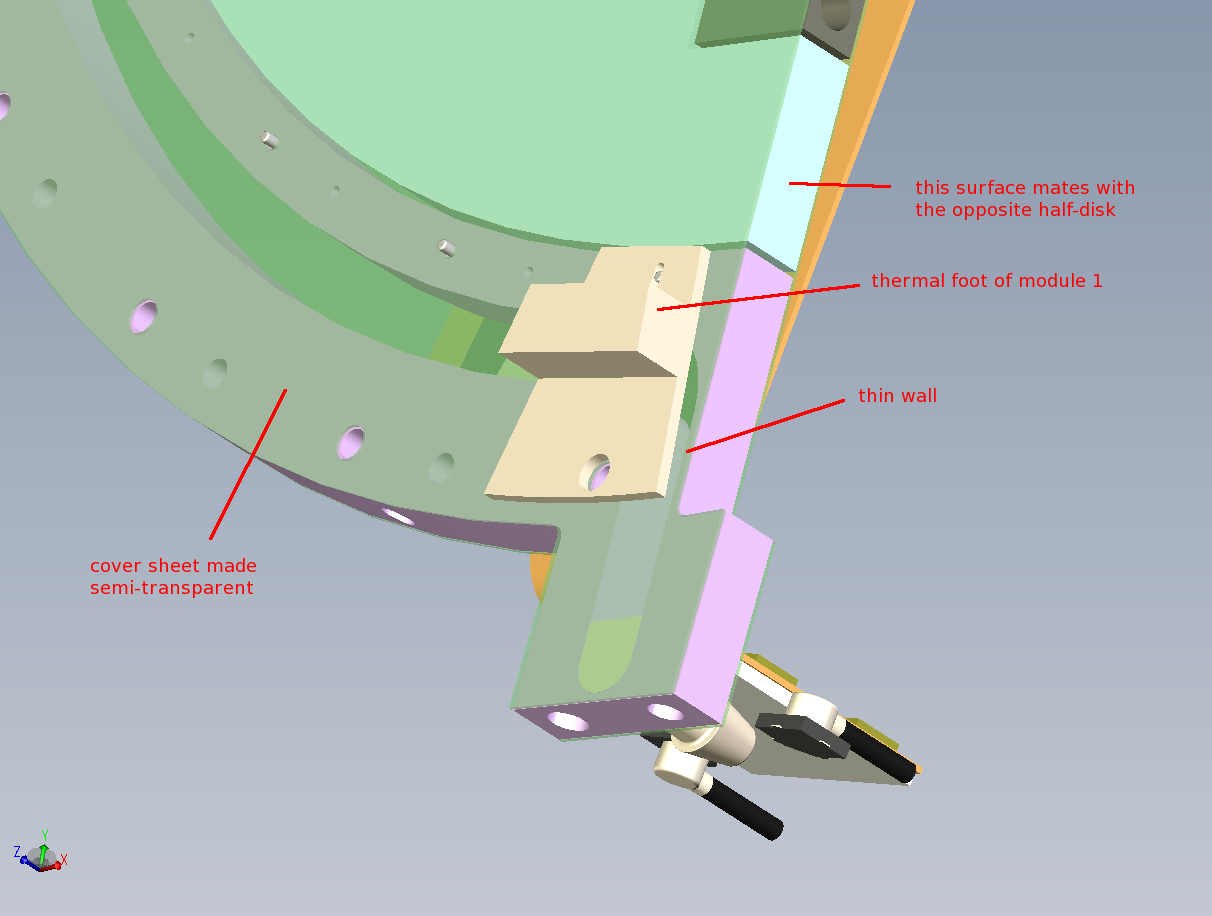

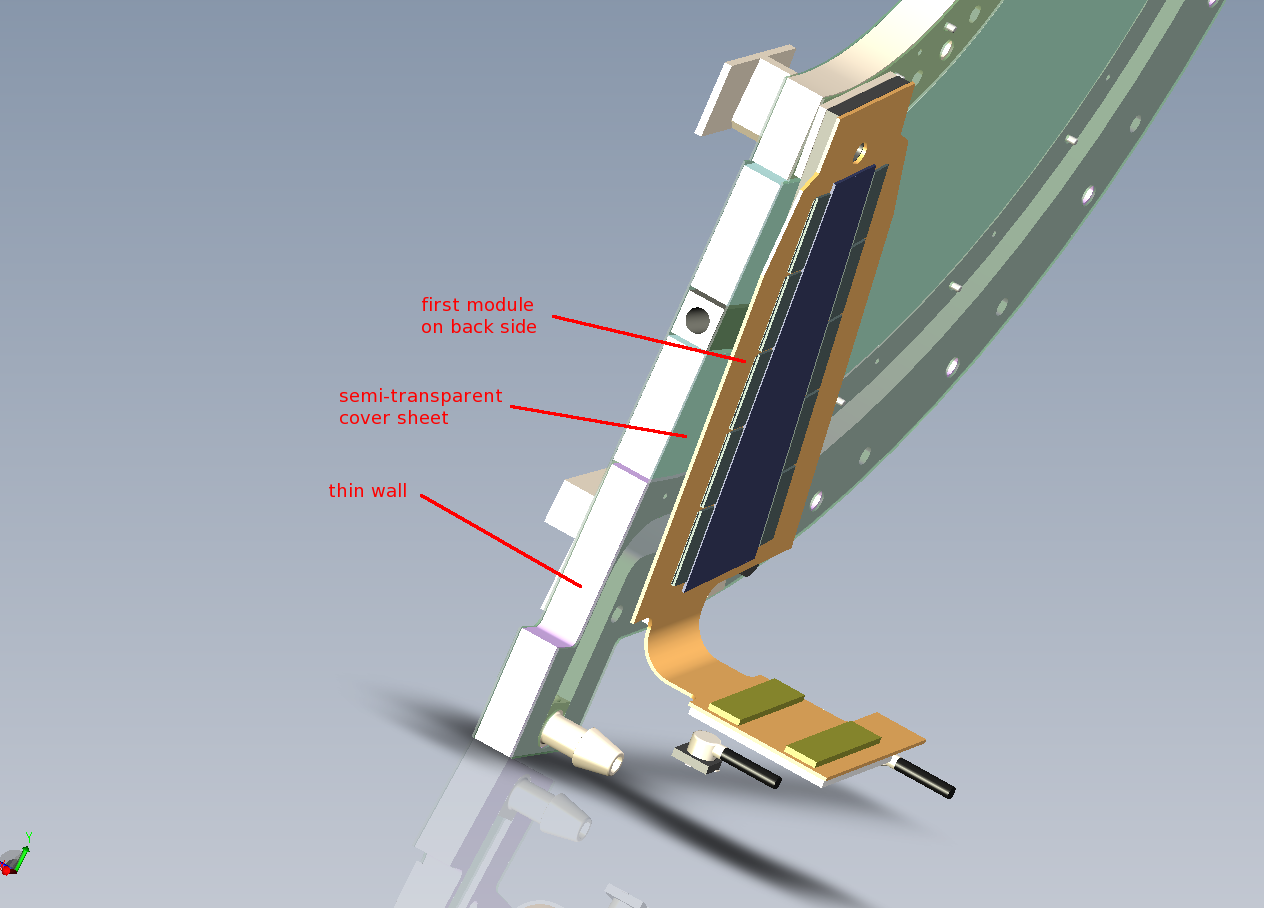

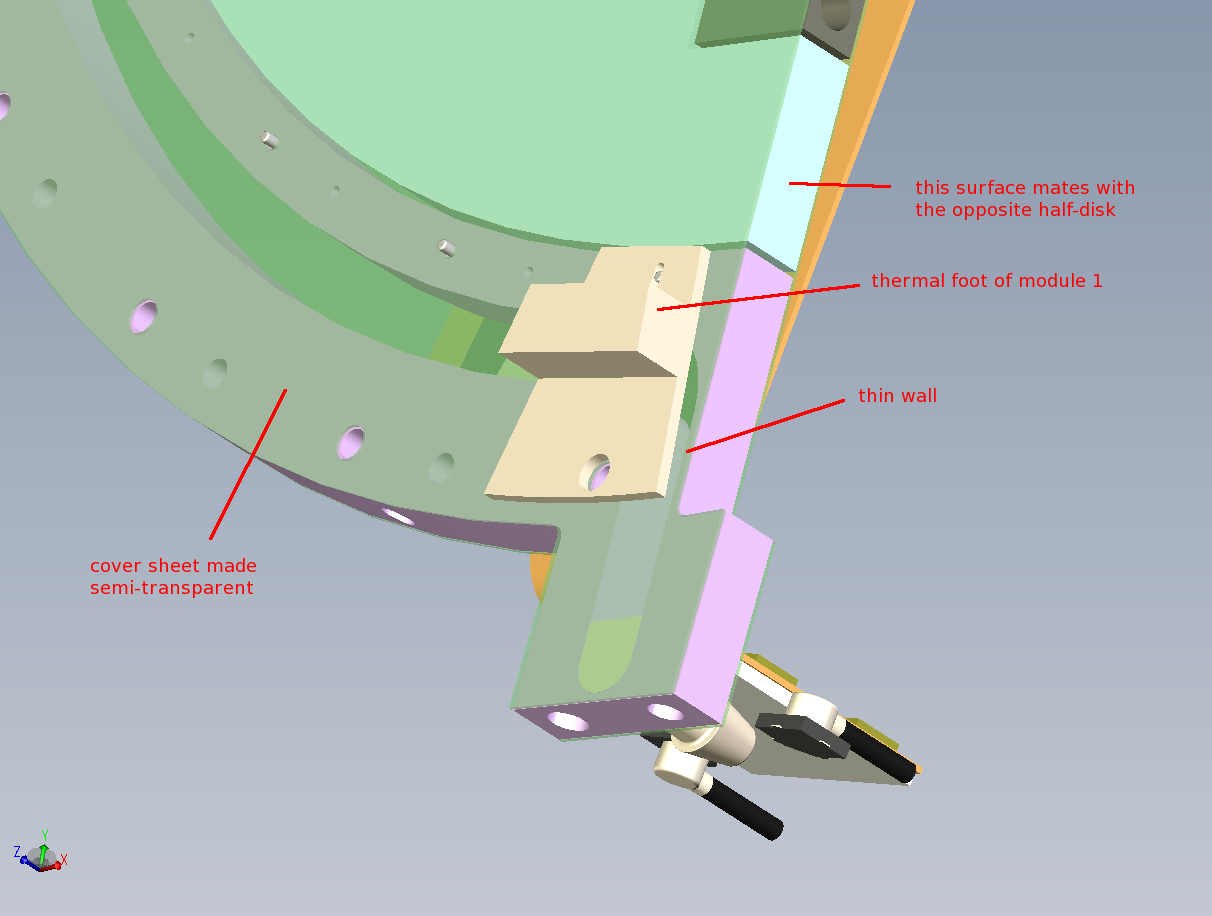

| Another weak spot is on station 1 bottom, where there is a very

thin wall. One thing that constrains a solution is that the

mid-plane edge of the half-disk mates with the half-disk on the opposite

side, so we cannot place a bracket or clamp across this thin wall. Using

tape to wrap this section would be a compromise between preventing a leak

and incurring a 100 um gap between the two halves.

The tape would have to extend under the foot (shown in white) of the

first module. This is not ideal, but on the other hand the foot

would help keep the tape from sliding or creeping.

|

|

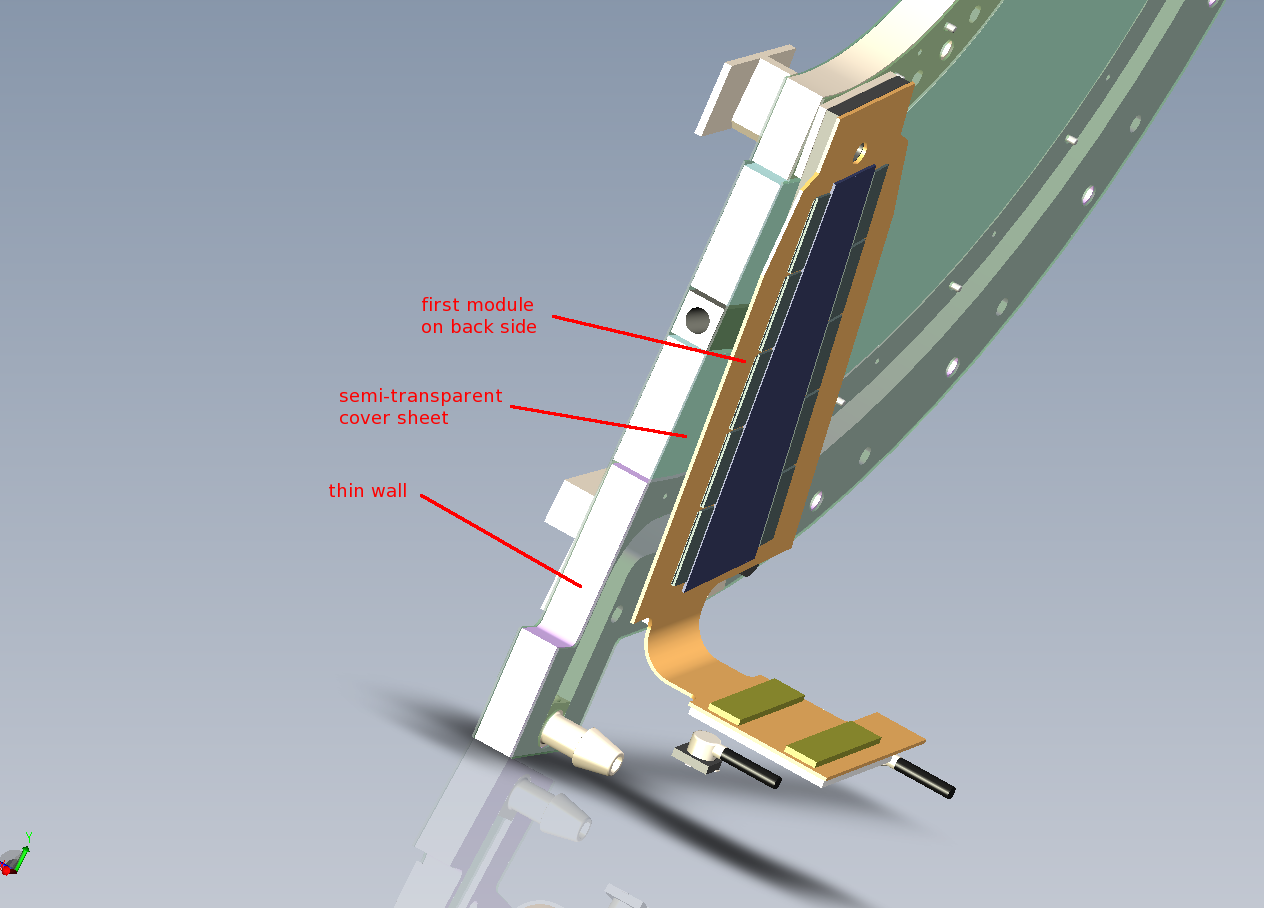

| On the backside, there is a bit more space for the tape.

|

|