Here is a movie that was taken by Jimmy Labounty during the installation preceeding run-13. A wire is connected to a union in a cooling line, and the alligator clip at the end of this wire sparks to a grounded piece of copper tape.

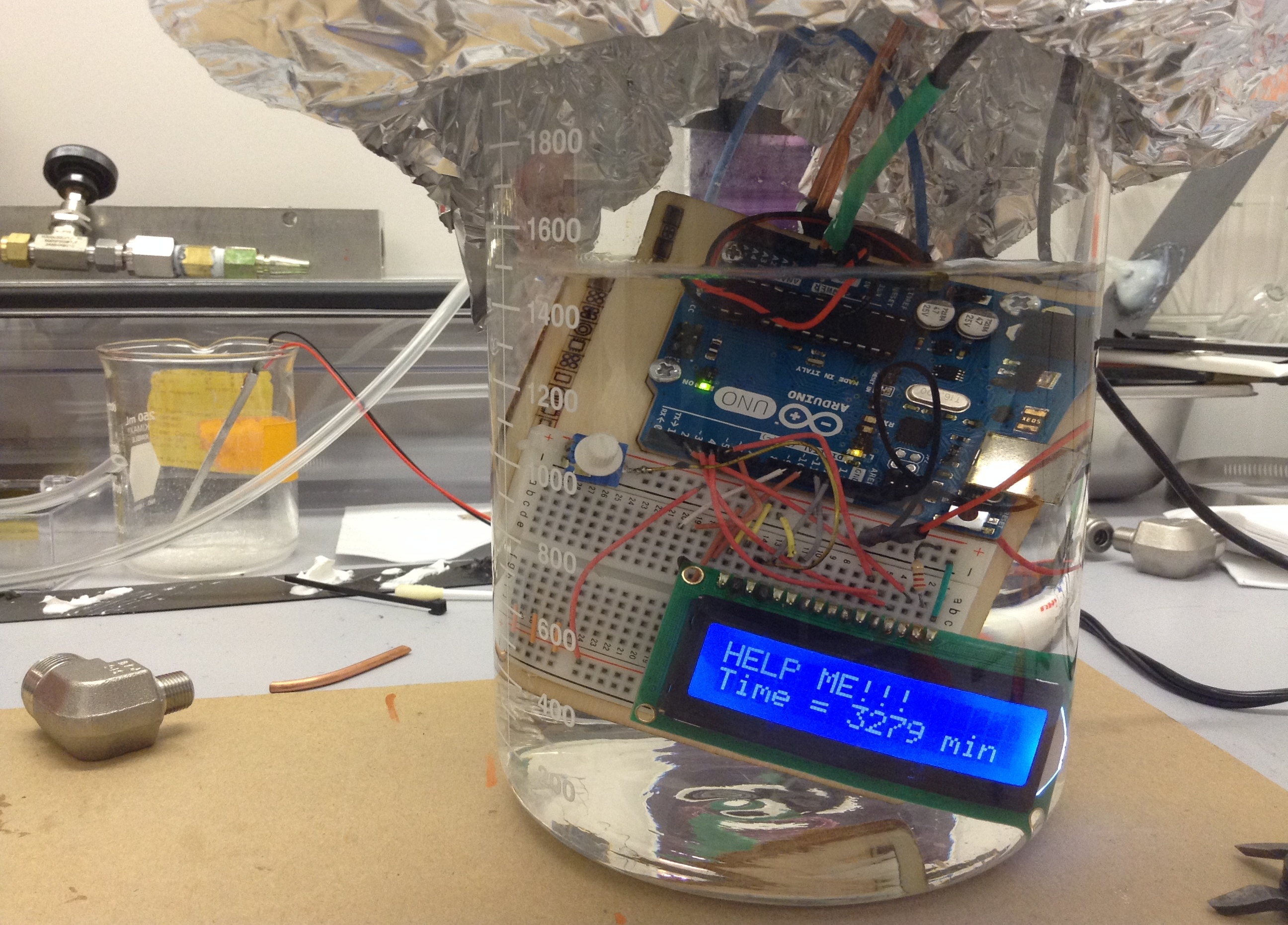

A small test setup was built, modeled on a tabletop Van de Graaff generator. The idea is that friction in the upgoing Teflon tube causes charge separation, which is picked off inside the top 'sphere'. This charges up and discharges to a grounded copper rod which is placed a few mm from the charge collector. Counting the number of sparks per minute is a crude relative measure of the effect.

Supply, return and grounding rod are tied together to ground

At the top, the hoses are connected with brass fittings, which touch the inside of the can.

A small Remcor chiller circulated the Novec. Supply pressure is about 8 psi, return pressure about 3 psi. The temperature can be varied between room temperature and 0°C.

From Rob Pisani, November 2013: Here is a nice video for you. I'm filling up the chillers and of course, the tank is charging up (a lot). Photo is of the set up. Drum and flex line are isolated. I had to run a ground wire to the valve on the drum. The pump is the same we used in the FVTX lab. The flex line on the output of the pump is grounded. The pump housing and impeller are plastic. As you can see from the frequency, there is a lot of charge being collected. the gap is about 2-3 mm.

Click to play → |

January 2014, from ROb Pisani:

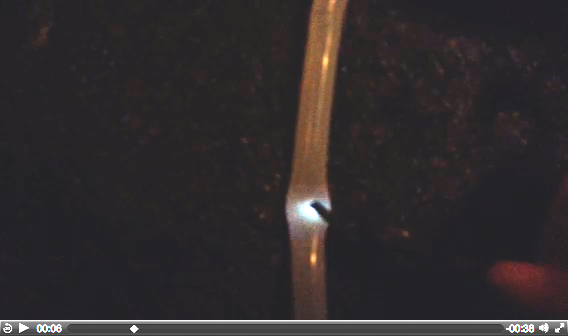

Here are some videos from todays repair. The first is me moving a flashlight along a tube where Novec was leaking. as you can see, a spark jumped out from the point. This charging up only happened at the output of the big wheels as before. The only difference with this area is that it comes out of the aluminum big wheel, to Tygon to Teflon to stainless. Sparking always happened 6-9 inches downstream of the Tygon inside the Teflon (7 tubes out of 20) at the output, you can feel the static on the Teflon tubes with your hand. I checked everywhere else and there was no noticeable charge buildup.

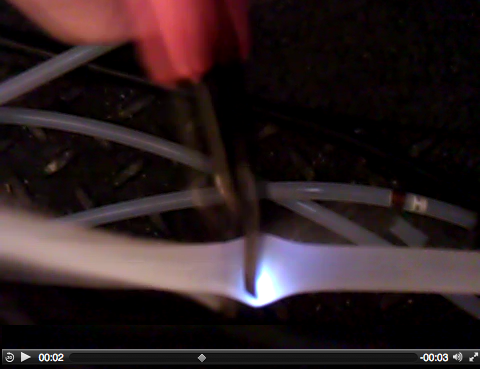

The second is even more interesting. We drained the system and were cutting damaged lines out of the system. One I was cutting up a piece to fit in a bucket. It discharged was I cut it. This piece was sitting on the table for about 20+ minutes. The video shows me snipping into the Teflon tubing every inch. I was the ground at this point. Every cut generated a spark. This tube was just sitting on the table. It had built up a lot of charge and was not dissipating. Even after 2 hours, this would happen. Very odd.

We ended up covering those lines with foil to hopefully dissipate the charge buildup. Im going to look into possibly replacing these lines with flexible stainless.

From Rob:

During today's access, we found some small leaks in the Teflon lines of the cooling system similar to those in the past. As before, the damaged lines were on the output of the big wheels (all 4 locations, 6 to 9 inches from the tygon connection point) Sparking at damaged areas was audible and visible (and recorded) . Static charge could be felt easily on the outside of those lines at all 4 locations. No charging or damage was found in any other locations. The damaged lines were replaced. In addition, the lines exiting the big wheels were covered with aluminum and grounded to help dissipate the charge before it does damage. Chiller was run at 13C first to check for charging. None was found after running about an hour. The High temp chiller was then set to its operating temp of 10C and reinspected.

I attached a video of one of the spark points. I believe that at the point we took the video, we had started warming up the cooling loop for the repair. the sparking was noticeable at 10C as well as at 13C.

Comment from Mike:

Not much to add except I have attached a short video of you cutting a very short section of Teflon tube we just removed from the detector. As you see in the video, the approximately 12" piece of tubing holds its charge for a while after being isolated from the detector. At this point, we have grounded or shielded most of the detector. The Teflon supply lines at the top of the detector don't seem to be affected by this phenomenon. As you, Jimmy and I discussed, maybe we should consider swapping out the lower Teflon with flexible SS. I worry though, about the inside wall of some of these flex lines. They are not what you would call "smooth".

On 2/19/2014 5:58 PM, Robert Pisani wrote:

>

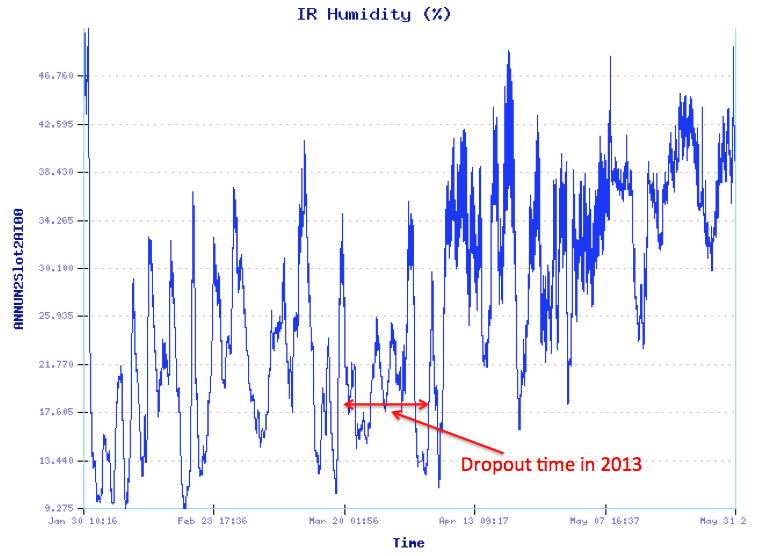

During the March 4 2014 discussion, the issue of ambient humidity came up. Melynda made this plot:

The low humidity may have made sparking more frequent, leading to the ROC dropout problems seen in that period. Also see Rob's pptx for this meeting, and these notes:

Found something interesting, extruded teflon's Dielectric

can be lower than film teflon. For our materials

Teflon is 1/32" thick, Tygon is 1/16" wall

*Dielectric Constant K

*Extruded teflon 2.1 (could be lower depending on

extrusion defects)

*Polyflow 2.26 (for example)

*Tygon (PVC based) 4.5

*Kapton 3.9

*Mylar 3.2

Our teflon tube may actually be the weakest link for breakdown.

****************************************

Robert Pisani

10 March 2014, from Rob:

Its alive! Check out the attached film. I was able to wire up a neon bulb and use it to search for charge in the set up in my lab. Very simple setup, tank to SS to tygon to pump to teflon to tygon to teflon to tank. Just a simple loop at room temp with different materials. Both the 1/8" and 3/16" tygon are in the loop. There is a SS coupling between everything. One interesting thing is that you can see the charge with the bulb without touching the coupling and charge builds up quickly. both the teflon and tygon generate charge. IF you leave it on for a while, you can get it to light up by going near the tube, not just the coupling. (say a few mm) Cant tell if one is worse than the other yet. this was a quick test.

From: Robert Pisani, Mon, May 19, 2014:

I finished up the testing of the anti-static additives that Hubert acquired. The Chemical is 3M's FC-4400. Sorry for the drawn out explanation, I just want to document the results with everyone.

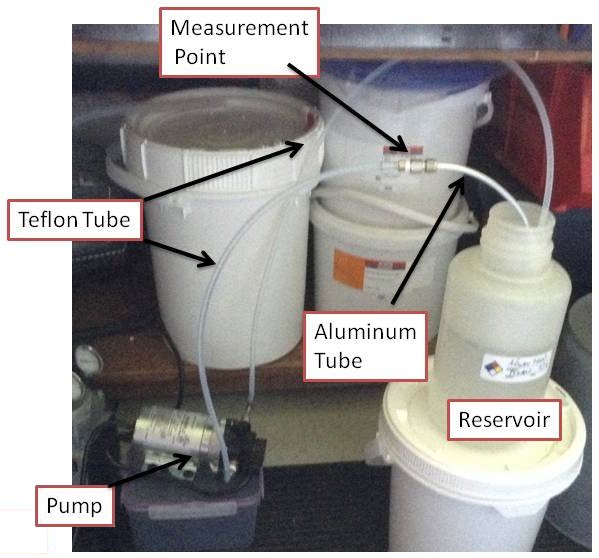

I set up a pump in my room with novec 7200 reservoir. Loop had a 1/4" Aluminum tube in the reservoir that was connected to the pump using a teflon tube. Another teflon tube then went from the pump back into the reservoir. Very simple loop (see attached Pict).

First test, turned the pump on with clean Novec. I immediately was able to measure a charge building on the Aluminum Tube. I grounded it a few times and the charge returned. I then added a few drops of the FC-4400 to the reservoir which contained about 6 quarts of novec. After about 30 seconds, the charge stopped building and actually dissipated. I ran this loop probably 20 times for as long as 2 hours and it never built up a charge. I also ran the fluid through a charcoal filter for many hours and still no charging.

To confirm the results, I set the loop up again with all new items (tubing, fittings pump and reservoir). When I turned on the system, the aluminum tube started charging immediately again. Repeated it a few times by discharging it. After confirming it was charging regularly, I then added 100mL of the old Novec containing the additive to the new reservoir which contained 3 quarts clean Novec. The charging stopped and actually started dissipating. I ran it for a few hours, and again no charging at all.

Conclusion, the FC-4400 works in extremely small concentrations. Only problem, I dont think I have a conclusive way to test its compatibility with our system in such small concentration. Probably will do nothing since we are possible looking at ppm levels.

On material compatibility: Jason M. Kehren (Senior Product Development Engineer 3M Electronics Markets Materials) wrote on 6/24/14:

FC-4400 is very stable and I would not expect any compatibility issues. However, we have not done any testing in a system like you will be using. Typically, the FC-4400 is used as an antistatic additive in polymer systems. I would not expect any issues with metals. We use metal reactors in the process of making FC-4400 with no issues. Additionally, the FC-4400 is used in metal extrusion equipment at temperatures ranging from 150 to 300 C with no reported issues. As the intended use of the FC-4400 is for polymer systems, I would not expect any compatibility issues with the polymers you mention.

One item that could be an issue is FC-4400 absorbing into the polymers. The main concern with this would be losing the performance that you are looking to gain by adding in the FC-4400 as it is no longer in the fluid.

Material compatibility tests: What has been done already (I think) is:

- Does it attack carbon composite surfaces

- Does is attack PEEK

- Does it attack our epoxy

- Does it leave a conducting residue

- Does it affect a silicon detector if a residue is deposited

'Most damage is on metal parts. Tin was removed form several pins. It collected on others. And this is at 5 volts. I don't know what the discolored coating on the parts are. It's not there when the board is soaked in clean Novec. 10 drops completely dissolves in the Novec with some string. The Arduino is not recoverable. I tried cleaning the board with different solutions and no luck.'