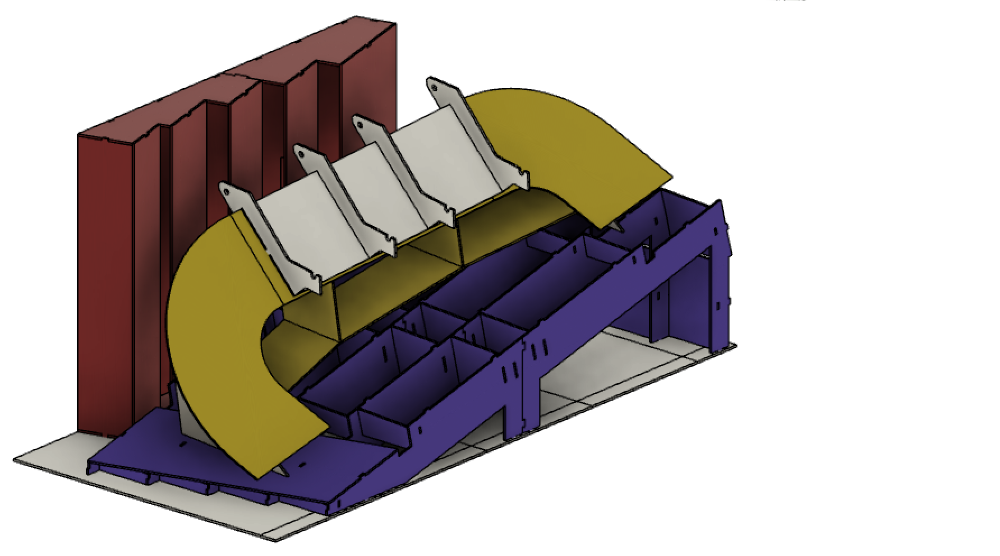

magnet coil brackets on the tilted coil and on the tapered bar

|

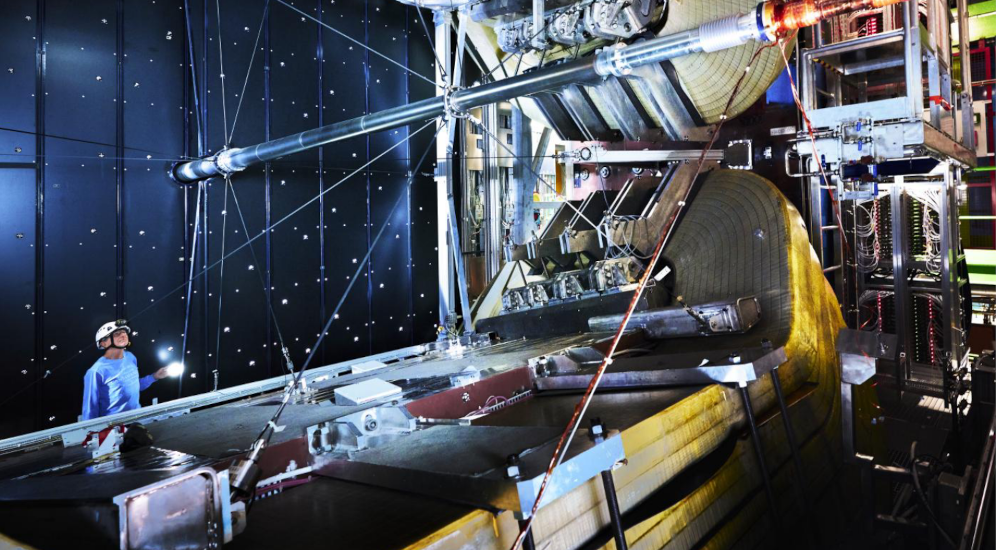

| If we cut along vertical planes that make an angle of

15° wrt the beampipe, we can make a slice that is 2.5m wide and

about 4m deep

|

|

| (in progress)

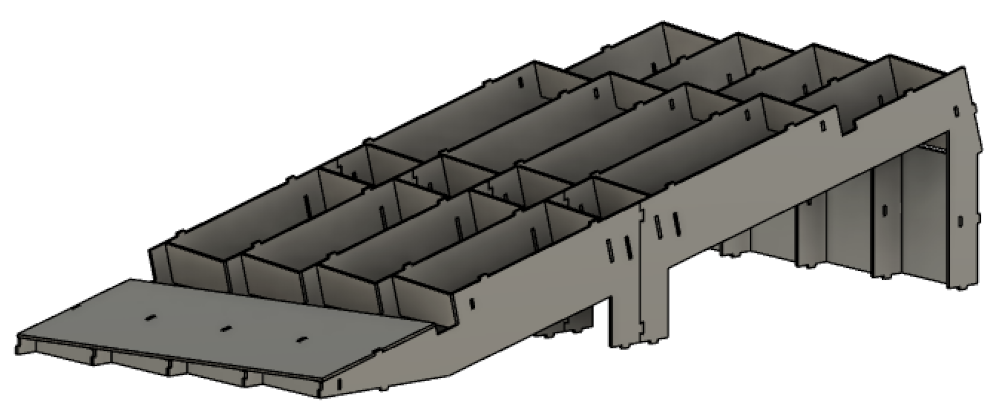

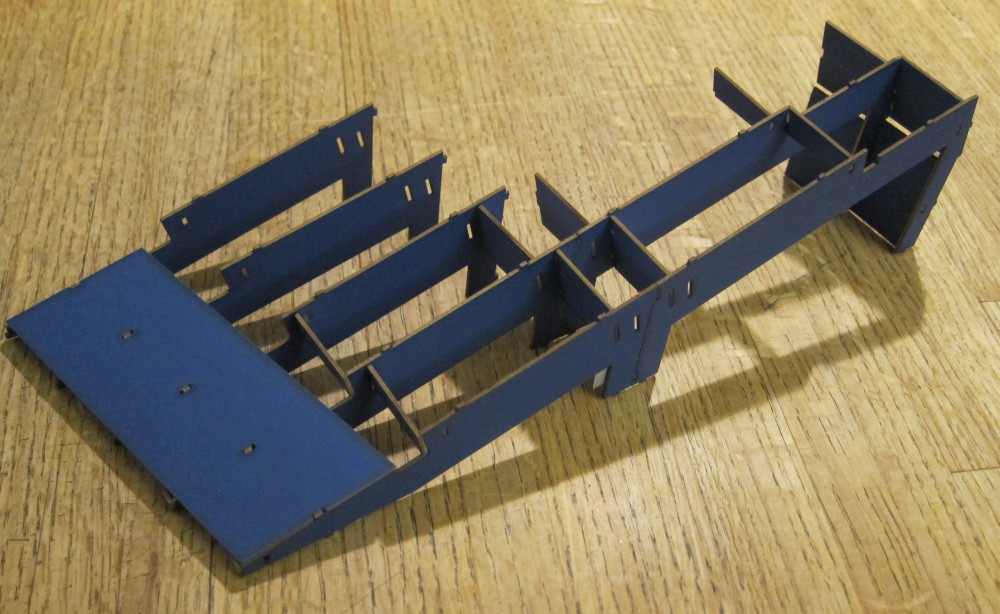

step file of plywood model

LHCb_half_partial_7_8_23.step

|

|

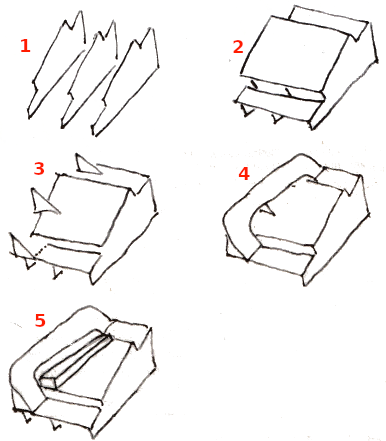

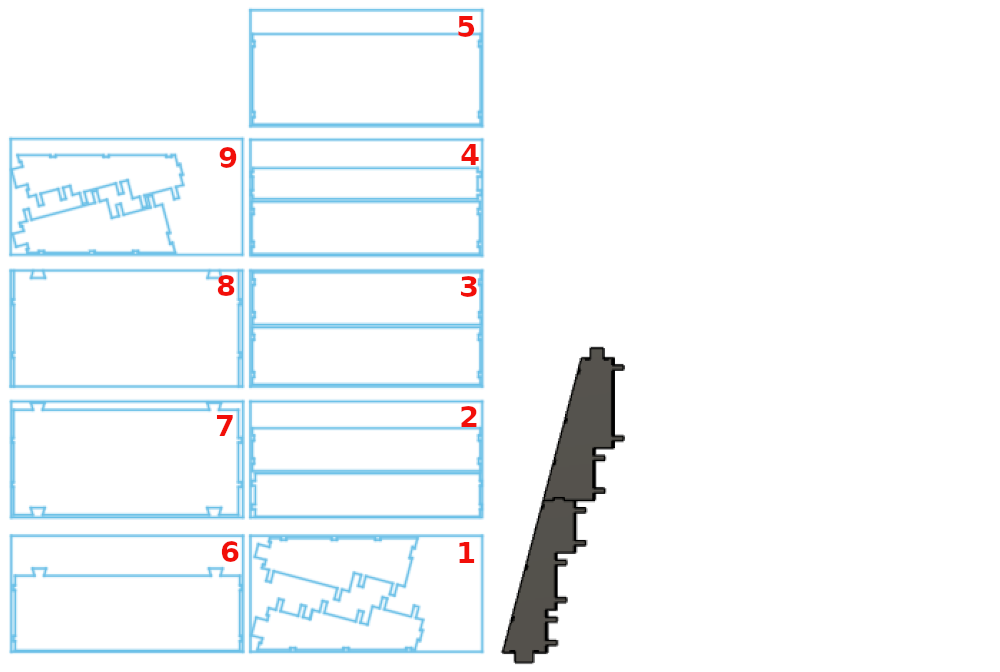

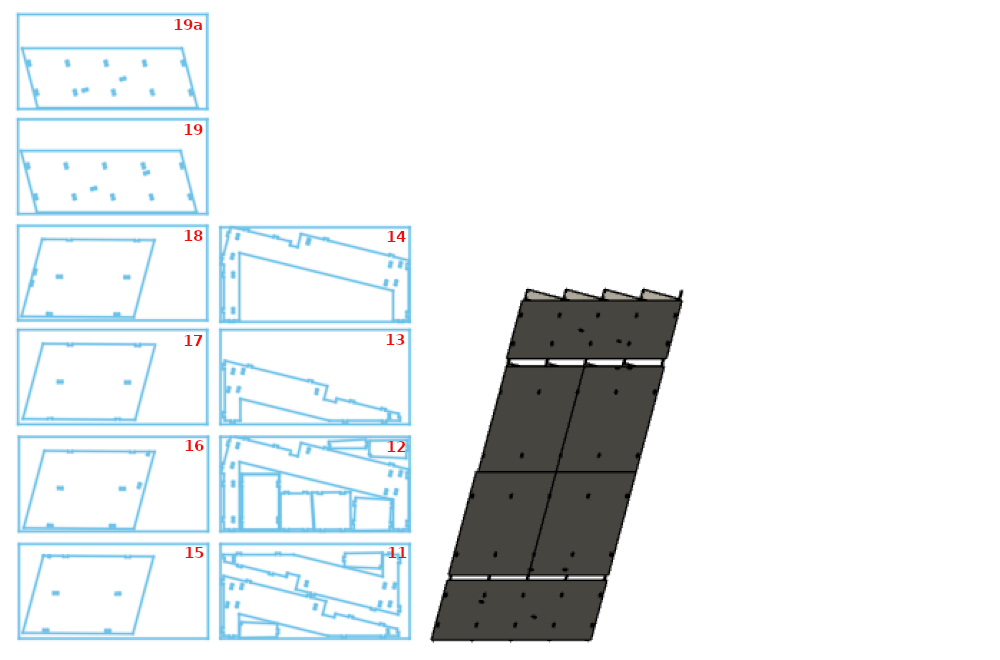

| The magnet wall subassembly

(

from this STEP file) fits on 9 4'×8' sheets.

sheet1.dxf

sheet2.dxf

sheet3.dxf

sheet4.dxf

sheet5.dxf

sheet6.dxf

sheet7.dxf

sheet8.dxf

sheet9.dxf

Scale 6% (1mm / 0.71")

|

|

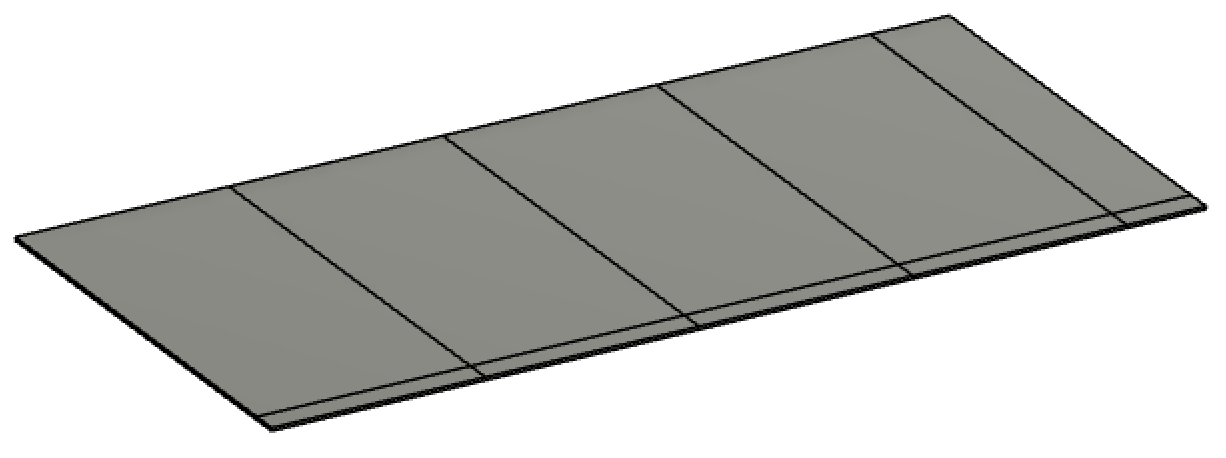

Footprint subassembly (needs tab pockets)

4 full sheets

4 6" stips

1 18* strip

1 6x18" piece

|

|

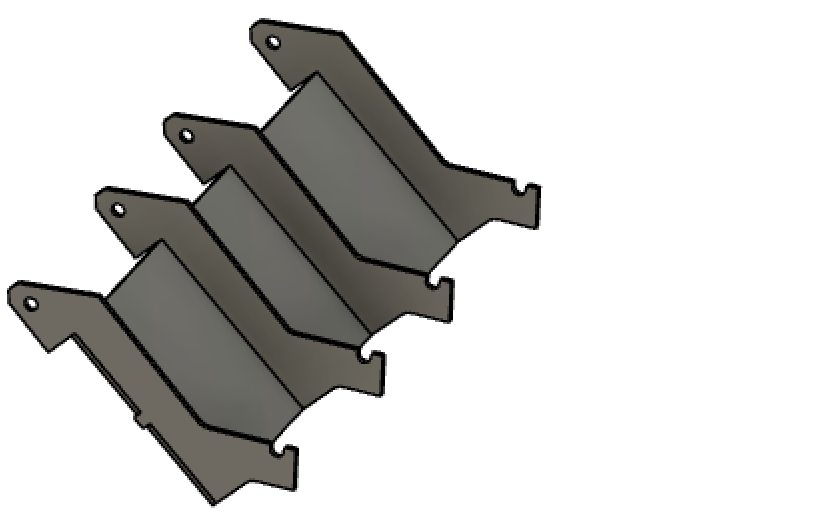

Lower magnet subassembly

brace1a

brace1b

brace1sup1

brace1sup2

brace1sup3

brace1sup4

brace1sup5

brace1sup10

magflatsa

|

|

4×8 sheets for the lower magnet subassembly

sheet11.dxf 2x

sheet12.dxf 4x

sheet13-19a.dxf 1x

Scale 6% (1mm / 0.71")

|

|

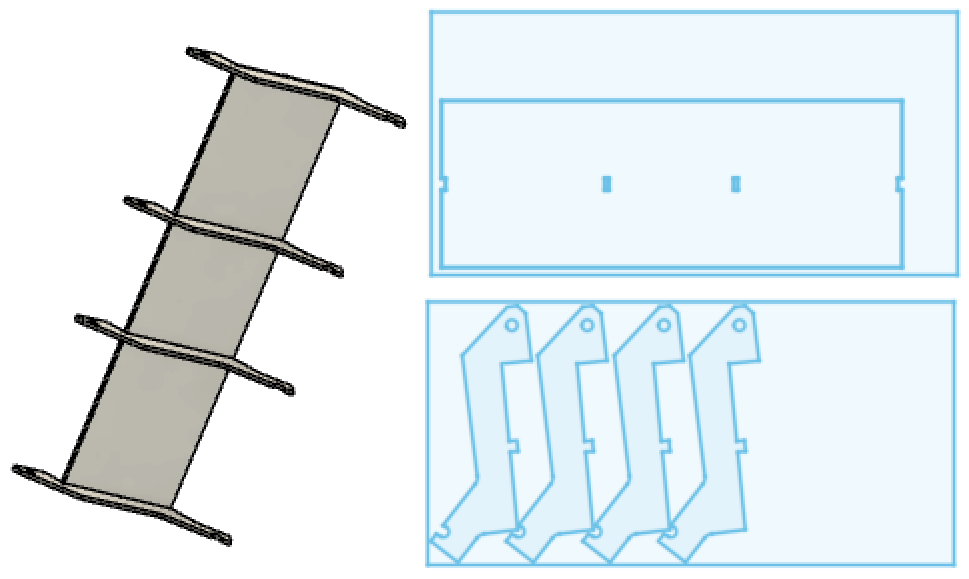

Magnet arms subassembly

sheet21.dxf

sheet22.dxf

|

|

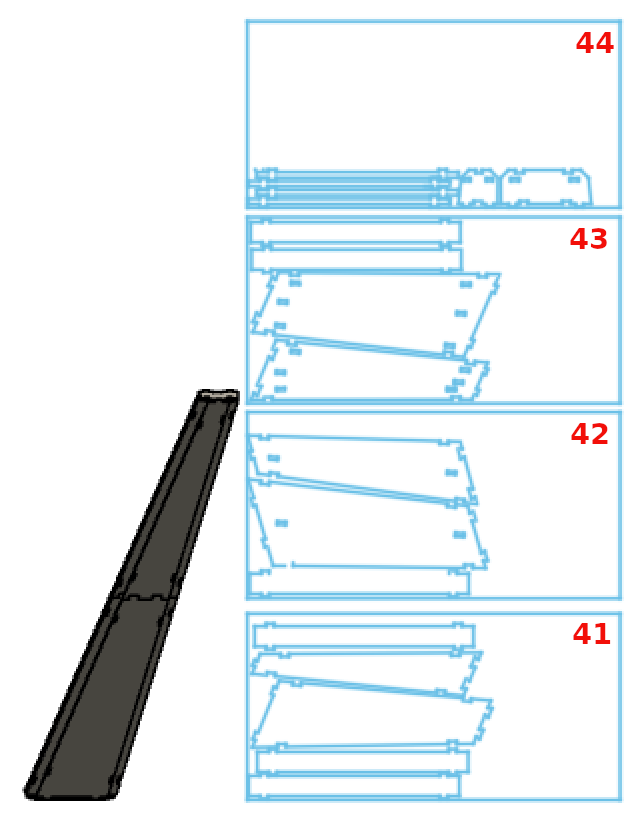

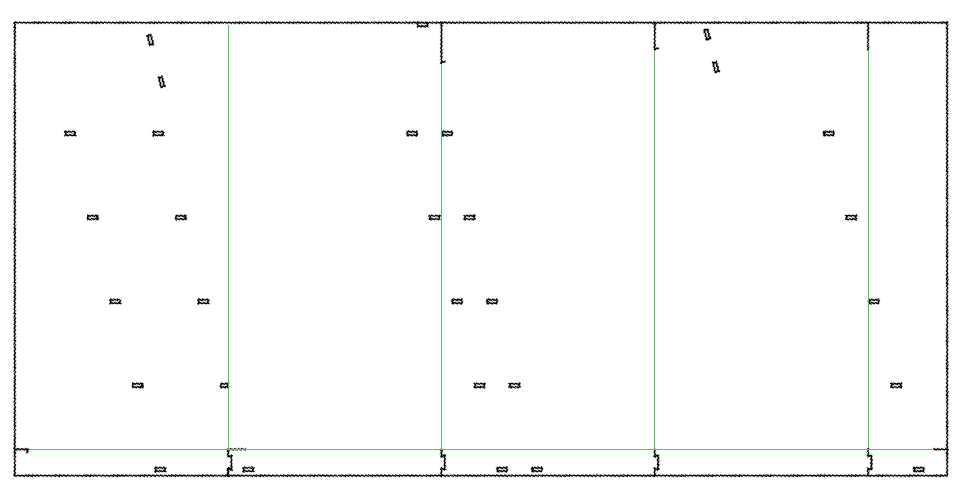

| Bar, no flange

sheet41.dxf

sheet42.dxf

sheet43.dxf

sheet44.dxf

|

|

| Magnet coil

sheet51.dxf

sheet52.dxf

sheet53.dxf

sheet54.dxf

sheet55.dxf

|

|

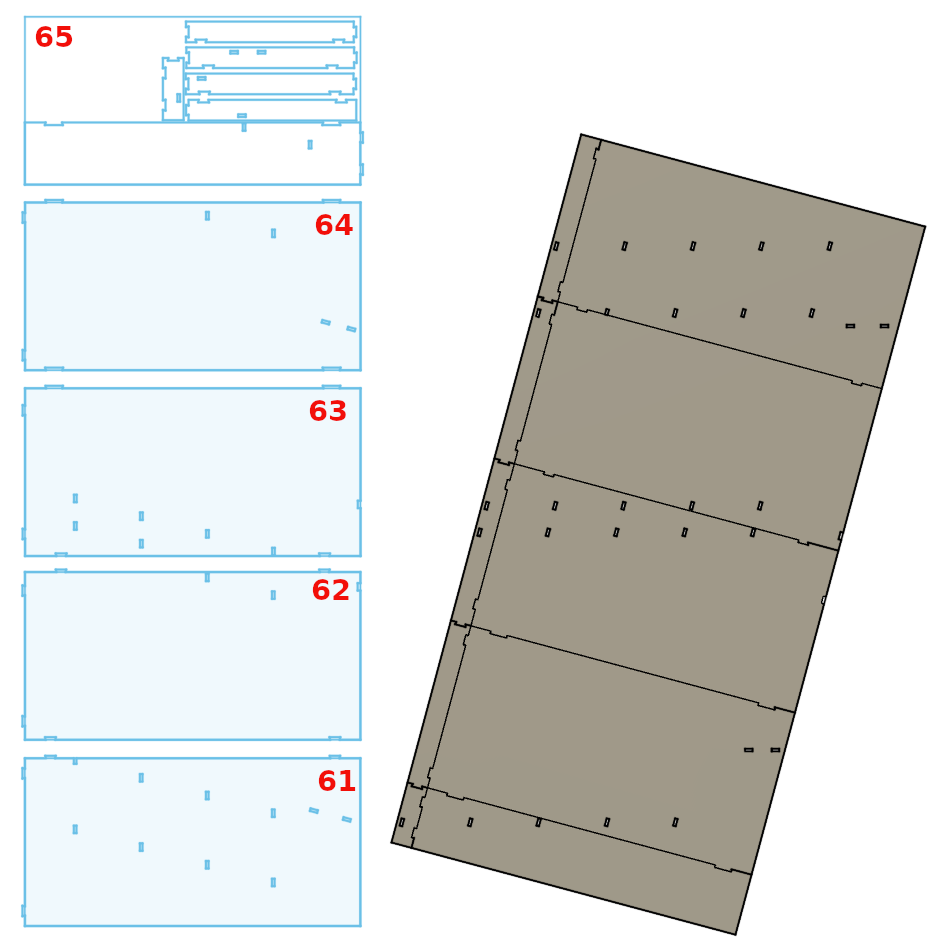

| Floor

floor.dxf

sheet61.dxf

sheet62.dxf

sheet63.dxf

sheet64.dxf

sheet65.dxf

Note sheets 61-64 are full sheets, and the tabs

protrude. Likely no problem - we can do without the tabs.

|

|

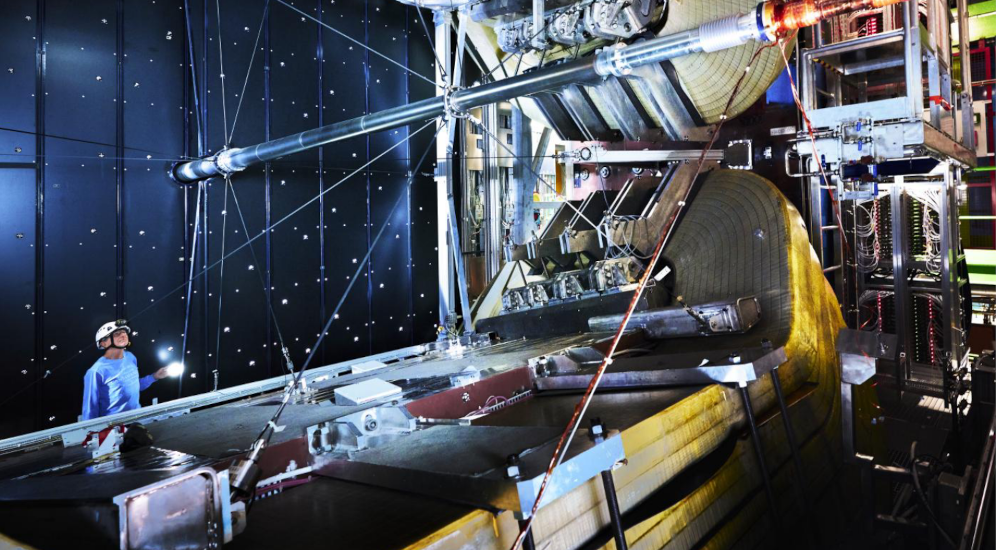

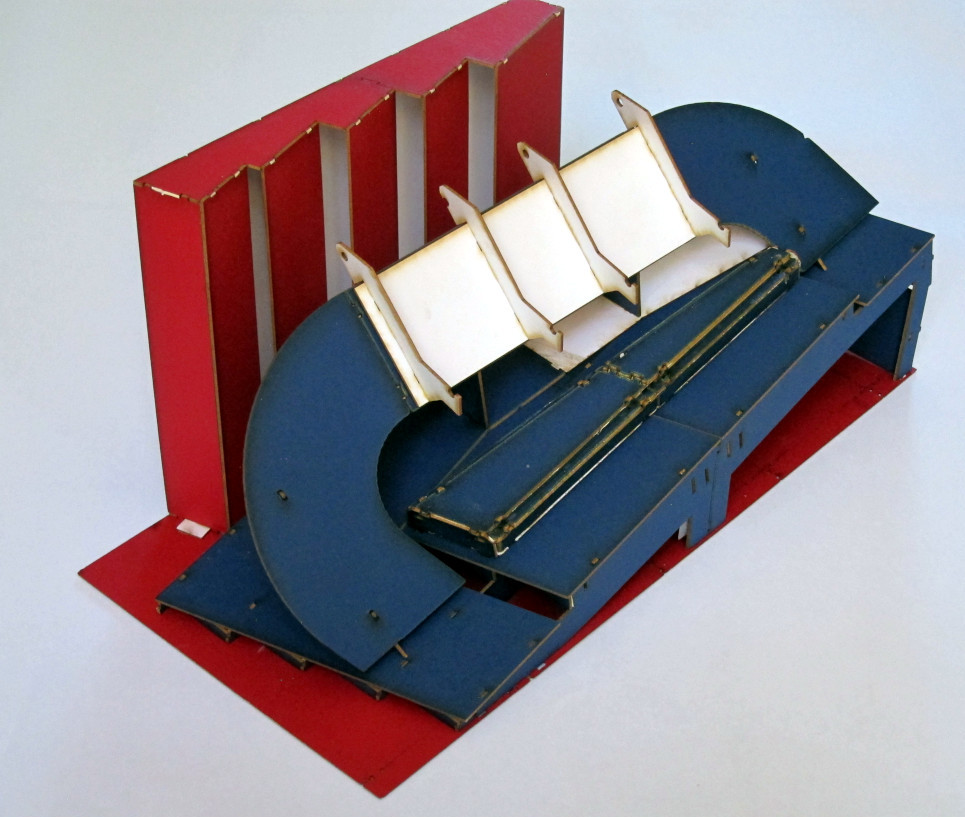

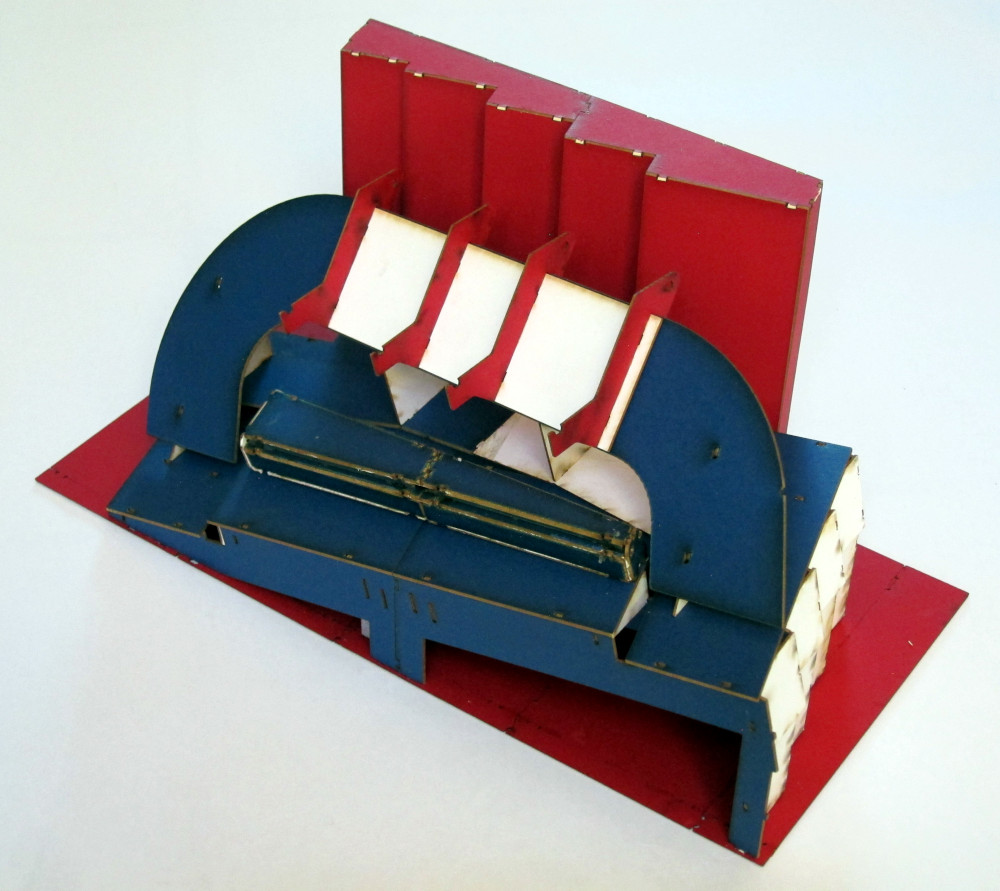

| Model, scale 6:100, model size 15.5×32×14.5 cm

The whole thing takes 42 4×8 sheets, one or two less if you

move things around a bit.

|

|

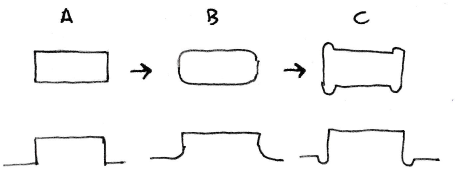

| The holes and tabs in the dxf files are as in A. If the router

follows this path, the holes and tabs will come out as in B. You

want to add little lines to cut shapes like C. Does the cutter

software add these automatically? We could add the lines and let the

cutter do it, or we can square the holes with a jig saw.

|

|