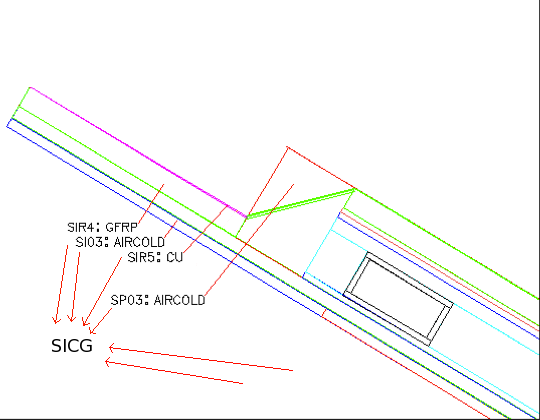

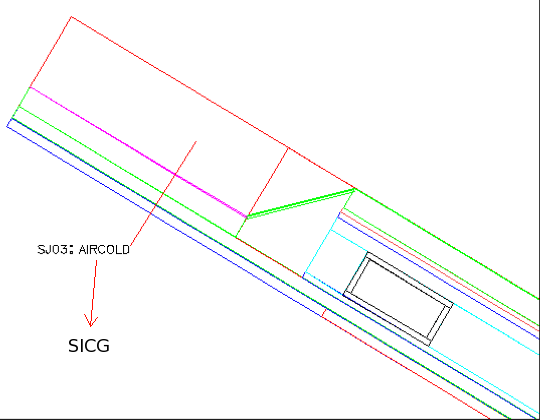

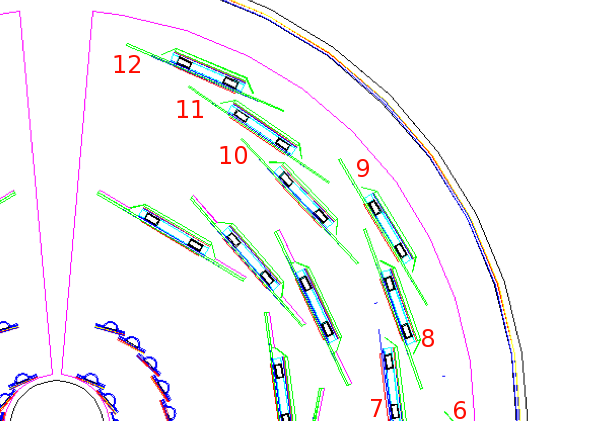

So I grouped the elements that make up a ladder together into a holder volume, so that you can move this single volume around.

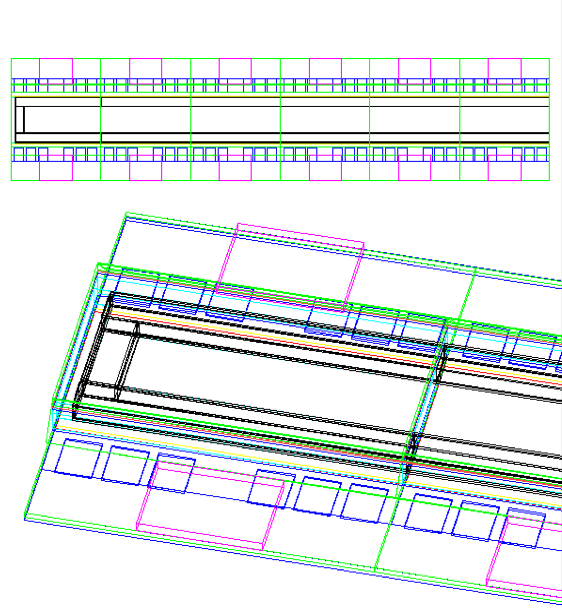

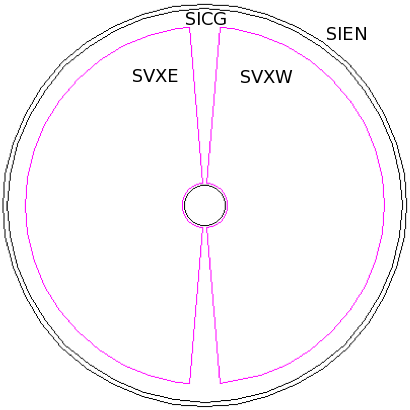

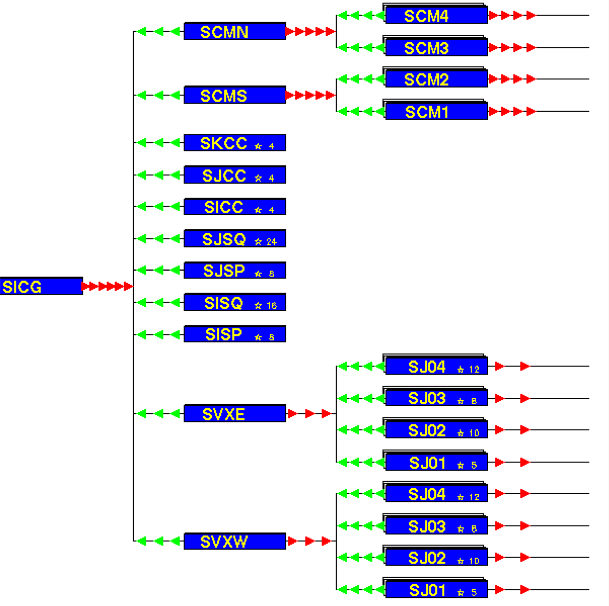

Right: In the new organization, all elements making up the layer 3 and 4 ladders are placed in a single holder volume, SJ03, SJ04 for layers 3 and 4, respectively.

GEANT> dcut sien 3 .1 -7 -45 5 5

GEANT> satt * seen 1 GEANT> satt sj04 seen 0 GEANT> satt sp04 seen 0 GEANT> next; draw sj04 80 140 0 40 3 2.0 2.0 GEANT> draw sj04 90 90 0 10 16 0.5 0.5

Group these together into SJ01 (for barrel 1) or SJ02 (for barrel2).

On the bottom, SVXE and SVXW are the barrel halves, each containing ladders SJ0x for barrels 1-4.

(The volumes in the middle, SKCC-SISP, are hoses, cables, manifolds, frames etc.)

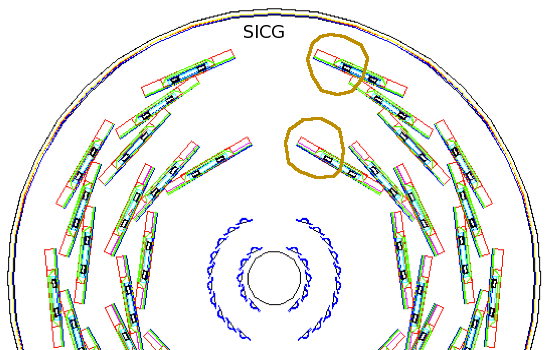

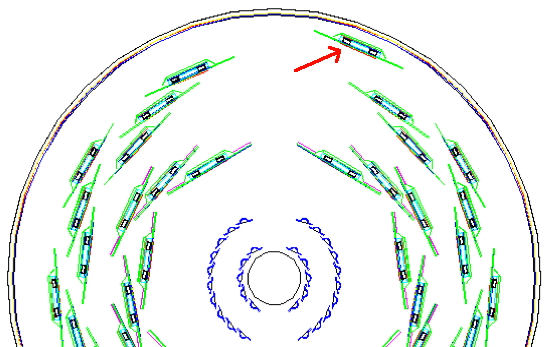

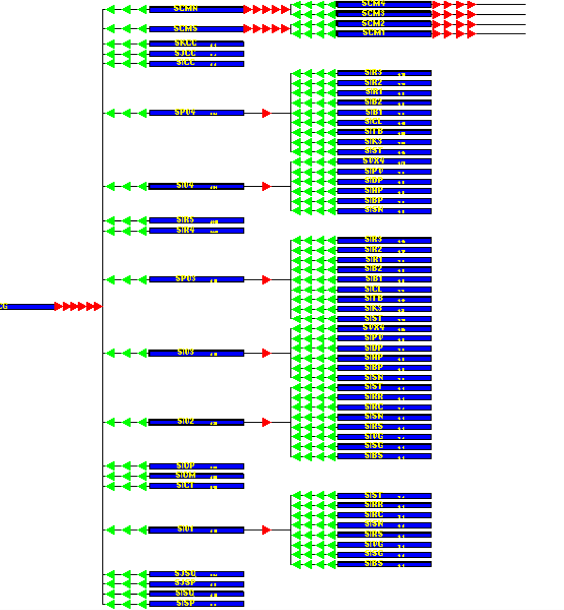

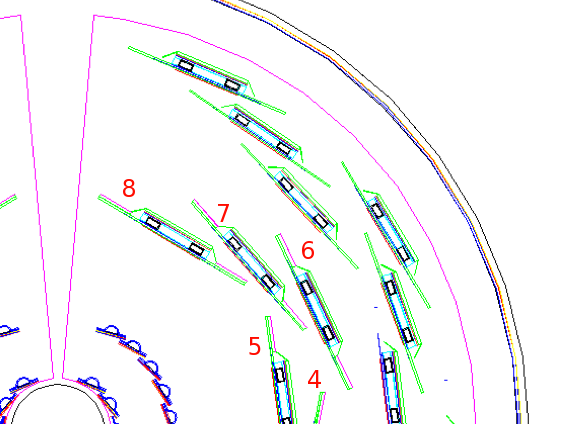

Here is the old organization, where many ladder elements were placed directly

into SICG. Almost impossible to read.

Here is the old organization, where many ladder elements were placed directly

into SICG. Almost impossible to read.

vtx/fvtx vtx ladder sensitive

hall enclosures east/west holder stave silicon

---------------------------------------------------------

HALL SIEN SICG SVXW SJ01 1 SI01 SISN

HALL SIEN SICG SVXE SJ01 6 SI01 SISN

HALL SIEN SICG SVXW SJ02 1 SI02 SISN

HALL SIEN SICG SVXE SJ02 11 SI02 SISN

HALL SIEN SICG SVXW SJ03 1 SI03 SISN

HALL SIEN SICG SVXE SJ03 9 SI03 SISN

HALL SIEN SICG SVXW SJ04 1 SI04 SISN

HALL SIEN SICG SVXE SJ04 13 SI04 SISN

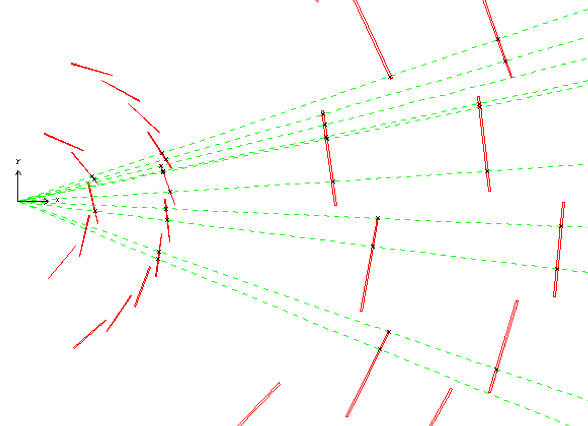

Single particle file cfmgmc.input

5 5 90 1 30 10 0. 0. 0. 0Picture:

GEANT> satt * seen 0 GEANT> satt sisn seen 1 GEANT> cfm_sngp GEANT> ptrig 1 GEANT> draw sicg 0 90 0 1 10 1 1 GEANT> dxyz GEANT> dhits GEANT> daxis 0 0 0 1

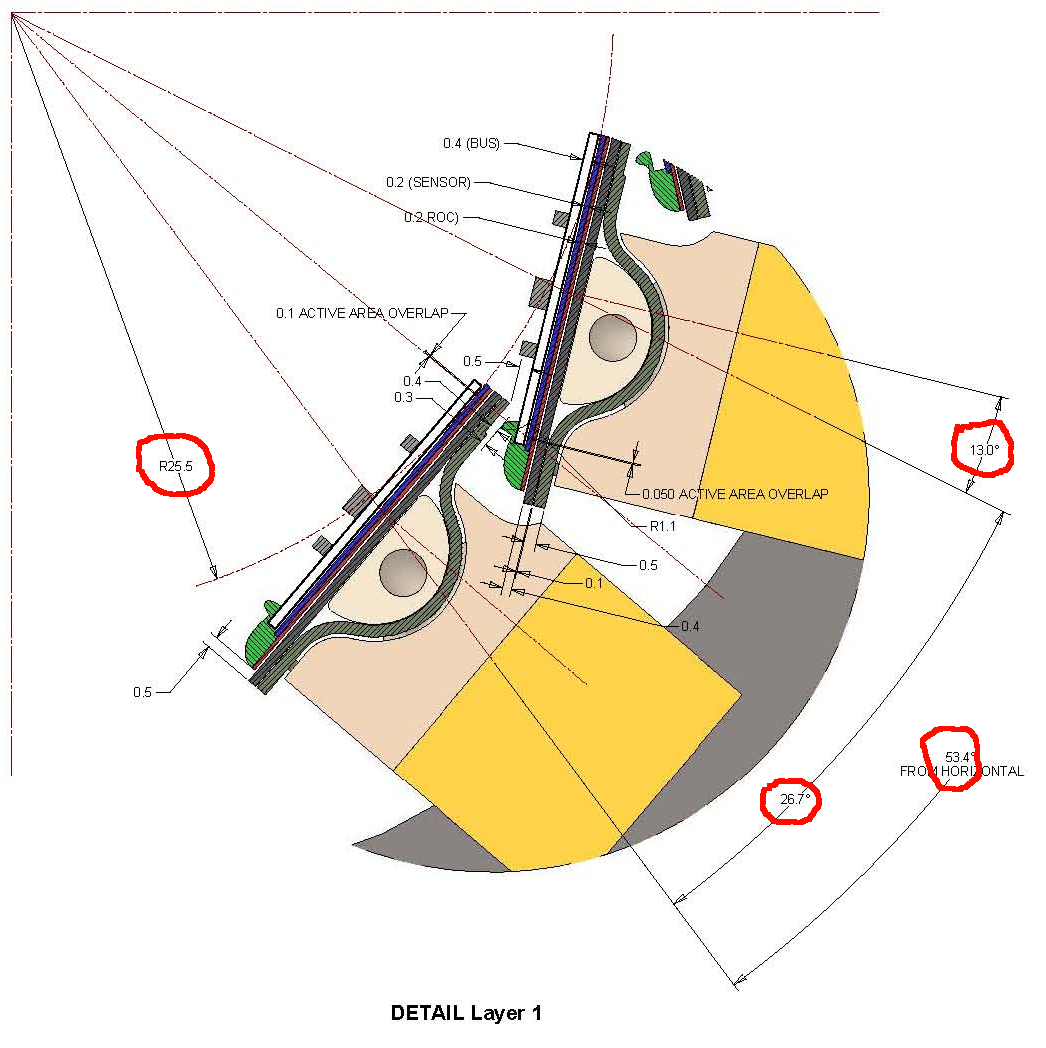

By reading svxPISA.par, you can make the table below:

ladder center tilt

radius angle angle

barrel, ----------- ------------ -----------

ladder old new old new old new

------------------------------------------------------

1 1 2.630 2.630 -53.400 -53.400 13.072 13.000

1 2 2.630 2.630 -26.700 -26.700 13.072 13.000

1 3 2.630 2.630 0.000 0.000 13.072 13.000

1 4 2.630 2.630 26.700 26.700 13.072 13.000

1 5 2.630 2.630 53.400 53.400 13.072 13.000

1 6 2.630 2.630 126.600 126.600 13.072 13.000

1 7 2.630 2.630 153.300 153.300 13.072 13.000

1 8 2.630 2.630 -180.000 180.000 13.072 13.000

1 9 2.630 2.630 -153.300 -153.300 13.072 13.000

1 10 2.630 2.630 -126.600 -126.600 13.072 13.000

-------------------------------------------------------

(output from compare1.f, which reads svxPISA.par)

This verifies that the barrel 1 ladders are placed correctly in the new organization. Note the tilt angle used to be off by a little.

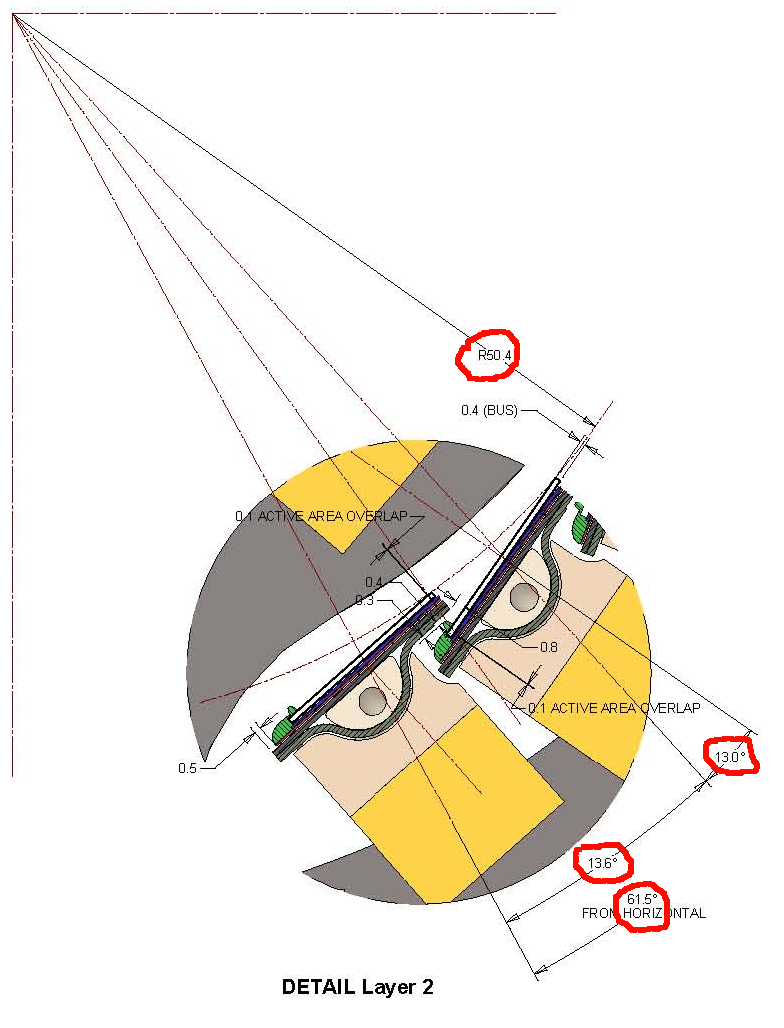

By reading svxPISA.par, you can make the table below:

barrel ladder sensor R angle tilt

----------------------------------------------

2 1 1 5.1300 -61.2000 13.0203 <- not 13.0000

2 2 1 5.1300 -47.6000 13.0198

2 3 1 5.1300 -34.0000 13.0202

2 4 1 5.1300 -20.4000 13.0201

2 5 1 5.1300 -6.7999 13.0202 <- not 5.12 cm

2 6 1 5.1300 6.7999 13.0203

2 7 1 5.1300 20.3999 13.0200

2 8 1 5.1300 34.0000 13.0199

2 9 1 5.1300 47.6000 13.0194

2 10 1 5.1300 61.2000 13.0195 <- not 61.5000

2 11 1 5.1300 118.8001 13.0195

2 12 1 5.1300 132.4000 13.0206

2 13 1 5.1300 146.0000 13.0199

2 14 1 5.1300 159.6000 13.0199

2 15 1 5.1300 173.2001 13.0203

2 16 1 5.1300 -173.2001 13.0199

2 17 1 5.1300 -159.6001 13.0197

2 18 1 5.1300 -146.0000 13.0199

2 19 1 5.1300 -132.4000 13.0195

2 20 1 5.1300 -118.8001 13.0200

------------------------------------------------

Note the discrepancies. What is going on?

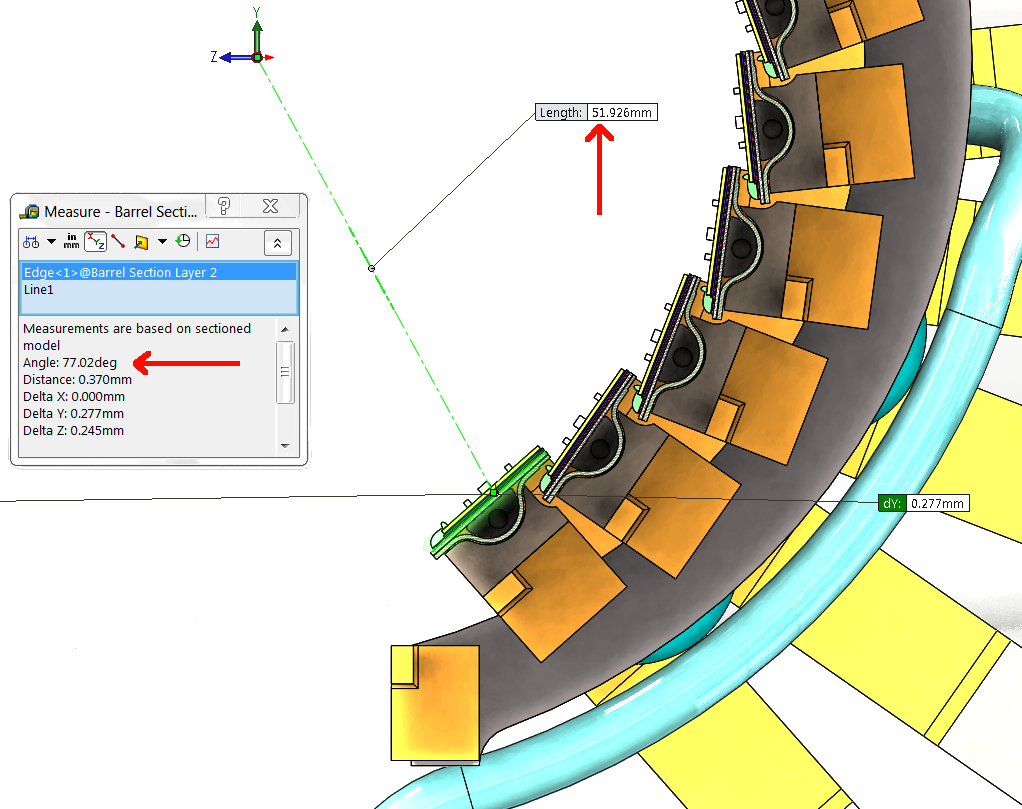

(12) So Walt and I went to the VTX 3D model and measured the distance from the origin to the center of the silicon sensor (51.926 mm), and the angle of the sensor w.r.t. the radius to the silicon center (77.02°). This means the tilt angle is 12.98°, not 13.02°. The radius of the circle tangent to the silicon surface is now 50.55 mm (was 50.4). The ladder-to-ladder angle was measured to be 13.626°

Entering these values in phnx.par, we now get:

ladder center tilt

radius angle angle

barrel, ----------- ------------ -----------

ladder old new old new old new

-------------------------------------------------------

2 1 5.130 5.193 -61.200 -61.317 13.057 12.980

2 2 5.130 5.193 -47.600 -47.691 13.057 12.980

2 3 5.130 5.193 -34.000 -34.065 13.057 12.980

2 4 5.130 5.193 -20.400 -20.439 13.057 12.980

2 5 5.130 5.193 -6.800 -6.813 13.057 12.980

2 6 5.130 5.193 6.800 6.813 13.057 12.980

2 7 5.130 5.193 20.400 20.439 13.057 12.980

2 8 5.130 5.193 34.000 34.065 13.057 12.980

2 9 5.130 5.193 47.600 47.691 13.057 12.980

2 10 5.130 5.193 61.200 61.317 13.057 12.981

2 11 5.130 5.193 118.800 118.683 13.057 12.981

2 12 5.130 5.193 132.400 132.309 13.057 12.980

2 13 5.130 5.193 146.000 145.935 13.057 12.980

2 14 5.130 5.193 159.600 159.561 13.057 12.980

2 15 5.130 5.193 173.200 173.187 13.057 12.980

2 16 5.130 5.193 -173.200 -173.187 13.057 12.980

2 17 5.130 5.193 -159.600 -159.561 13.057 12.980

2 18 5.130 5.193 -146.000 -145.935 13.057 12.980

2 19 5.130 5.193 -132.400 -132.309 13.057 12.980

2 20 5.130 5.193 -118.800 -118.683 13.057 12.980

-------------------------------------------------------

(output from compare1.f, which reads svxPISA.par)

Note the Barrel2 ladders have moved in r, phi and tilt.

ladder center tilt

radius angle angle

barrel, ----------- ------------ -----------

ladder old new old new old new

-------------------------------------------------------

3 1 11.765 11.765 -61.410 -61.410 0.000 0.000

3 2 10.360 10.387 -43.370 -43.370 0.000 0.000

3 3 12.848 13.143 -26.210 -26.210 0.000 0.000

3 4 11.765 11.765 -10.150 -10.150 0.000 0.000

3 5 10.360 10.387 7.890 7.890 0.000 0.000

3 6 12.848 13.143 25.050 25.050 0.000 0.000

3 7 11.765 11.765 41.110 41.110 0.000 0.000

3 8 10.360 10.387 59.150 59.150 0.000 0.000

3 9 10.360 10.387 120.850 120.850 0.000 0.000

3 10 11.765 11.765 138.890 138.890 0.000 0.000

3 11 12.848 13.143 154.950 154.950 0.000 0.000

3 12 10.360 10.387 172.110 172.110 0.000 0.000

3 13 11.765 11.765 -169.850 -169.850 0.000 0.000

3 14 12.848 13.143 -153.790 -153.790 0.000 0.000

3 15 10.360 10.387 -136.630 -136.630 0.000 0.000

3 16 11.765 11.765 -118.590 -118.590 0.000 0.000

-------------------------------------------------------

After code fixes, the radii have changed by 0.27, 0, 2.95 mm for inner, middle, outer ladders, and match the as-built drawings.

From compare3.f

Silicon thickness (from phnx.par) 0.625 mm.

Raw numbers from the as-built 3-D model, distances from the front face

of the silicon to (0,0,0):

Front surface Si volume center

---------------------------------------

inner 103.56 mm 103.87 mm

middle 117.34 mm 117.65 mm

outer 131.13 mm 131.44 mm

---------------------------------------

(14) Layer 4:

ladder center tilt

radius angle angle

barrel, ----------- ------------ -----------

ladder old new old new old new

-------------------------------------------------------

4 1 15.473 15.546 -65.130 -65.130 0.000 0.001

4 2 16.687 16.687 -52.690 -52.690 0.000 0.000

4 3 17.901 17.828 -41.120 -41.120 0.000 0.000

4 4 15.473 15.546 -29.080 -29.080 0.000 0.000

4 5 16.687 16.687 -16.640 -16.640 0.000 0.000

4 6 17.901 17.828 -5.070 -5.070 0.000 0.000

4 7 15.473 15.546 6.970 6.970 0.000 0.000

4 8 16.687 16.687 19.410 19.410 0.000 0.000

4 9 17.901 17.828 30.980 30.980 0.000 0.000

4 10 15.473 15.546 43.020 43.020 0.000 0.000

4 11 16.687 16.687 55.460 55.460 0.000 0.000

4 12 17.901 17.828 67.030 67.030 0.000 0.000

4 13 17.901 17.828 112.970 112.970 0.000 0.000

4 14 16.687 16.687 124.540 124.540 0.000 0.000

4 15 15.473 15.546 136.980 136.980 0.000 0.000

4 16 17.901 17.828 149.020 149.020 0.000 0.000

4 17 16.687 16.687 160.590 160.590 0.000 0.000

4 18 15.473 15.546 173.030 173.030 0.000 0.000

4 19 17.901 17.828 -174.930 -174.930 0.000 0.000

4 20 16.687 16.687 -163.360 -163.360 0.000 0.000

4 21 15.473 15.546 -150.920 -150.920 0.000 0.000

4 22 17.901 17.828 -138.880 -138.880 0.000 0.000

4 23 16.687 16.687 -127.310 -127.310 0.000 0.000

4 24 15.473 15.546 -114.870 -114.870 0.000 -0.001

-------------------------------------------------------

After code fixes, the radii have changed by 0.73, 0, 0.73 mm for inner, middle, outer ladders, and match the as-built drawings.

From compare3.f

Silicon thickness (from phnx.par) 0.625 mm.

Raw numbers from the as-built 3-D model, distances from the front face

of the silicon to (0,0,0):

Front surface Si volume center

---------------------------------------

inner 155.143 mm 155.455 mm

middle 166.555 mm 166.868 mm

outer mm mm

---------------------------------------

(15) Summary:

- The VTX Geant3 volume tree was reorganized such that

- All components that make up a ladder are placed together in a

holder volume (one per ladder)

- West VTX ladders are placed in SVXW, east in SVXE, and these

two are places in the (F)VTX cage.

- The VTX Pisa code can read a SQL database record containing small

displacements for each ladder, and for each of the VTX halves.

- The placement of the ladders was checked against the as-built

engineering drawings, and the code was corrected to match this geometry,

resulting in shifts and rotations wrt the previous version of the code.

(16) How to interface with the alignment system?

- PISA produces an output file svxPISA.par, which contains a description

of the position and orientation of each SVX sensor chip (x,y,z and

rotation matrix).

- svxPISA.par is read in by the offline code to establish the VTX

geometry.

- The alignment software operates on this geometry, and produces a new

svxPISA.par.

Now what is needed is a way to read this new file into PISA, so that

simulations can be run that match the data. This file cannot be used directly

to construct the VTX. However, by comparing svxPISA.par from an unmodified

PISA run with the version produced by the alignment software, you can easily

find the delta-x,y,z between the two files. These deltas can then be used

by PISA to position the ladders. So if you give PISA these two files, it can

produce the modified geometry. The procedure is:

- Run PISA unmodified to make a 'clean' svxPISA.par (just start/stop,

no need to generate any events)

- Run PISA again, this time giving it both the 'clean' and the

modified versions of svxPISA.par.

Also see: Fix the offline software to

recognize the new hierarchy.