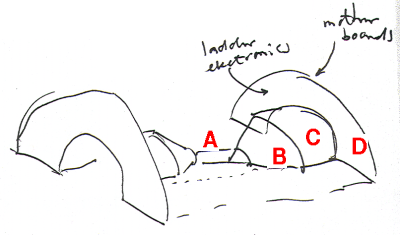

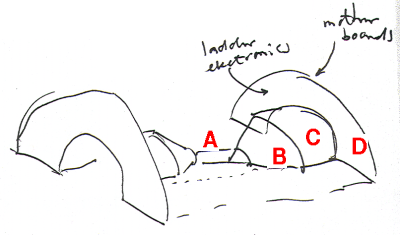

Cartoons of an assembly that allows sequential mounting of barrel layers

1,2 and 3,4, and independent mounting of endcaps.

Start with an assembly consisting of

- beam pipe cover

- barrel ladder support cone

- endcap radial outer cover cylinder

- endcap electronics carrier board

You can now mount the barrel ladders. Ladders are fixed to support

cone B, cables are guided along B and C, and electronics are mounted to

the inside of the carrier board D.

|

|

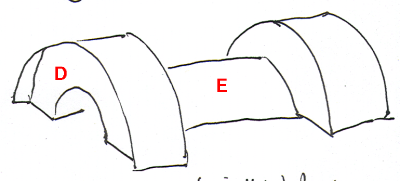

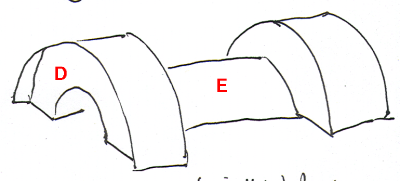

| An outer cover is mounted over the assembly, which can

have either 2 or 4 layers in it. The outer surface of the carrier board is

still visible.

|

|

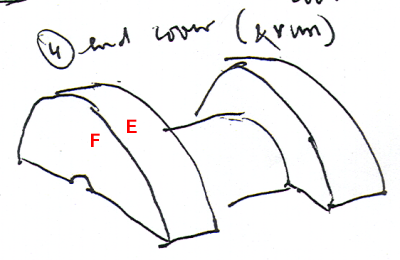

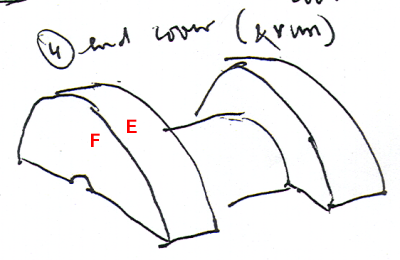

| An endplate cove F is mounted. Barrel is ready to run.

|

|

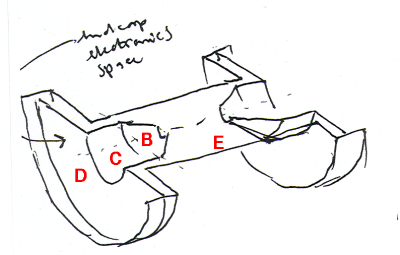

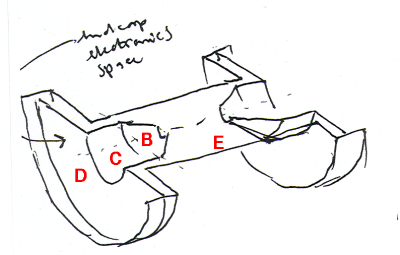

Alternatively, you can turn the assembly over, and

mount the endcaps inside cone B and cylinder C, with electronics mounted

on the other side of carrier board D.

After this, mount the endplate F (from the previous picture). In addition, you

can add beampipe covers over the endcaps. These go between beampipe cover

A (from the top picture) to the endplates F.

|

|

The carrier boards D are the main anchor plates. These can be made very

stiff and hold the connections to the external mount points.

For strength, a series of posts going radially out from the joint between B

and C can connect to outer cover C. The posts need to go in between barrel

cables, pipes etc. Also posts parallel to the beampipe connecting outer cover

E to the carrier boards, at the inner radius (~20cm) of E.

The halves have little strength against twisting around the z-axis, but are

very strong against twist after the two halves are locked together.

Last update 17 June 2005 - HvH