MCM Output Cable Quality Assurance Procedure

Toshiyuki Shiina

The University of Alabama in Huntsville

PHENIX-MVD-99-4, PHENIX Note 372

1. Introduction

2. Setup and Procedure

a) Continuity Test

b) Short Test

3. Result

Appendix A. MCM to Power Communication (or

Daughter) Board Pin Assignments

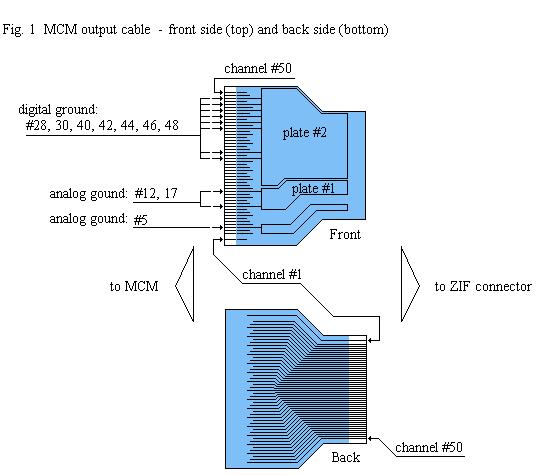

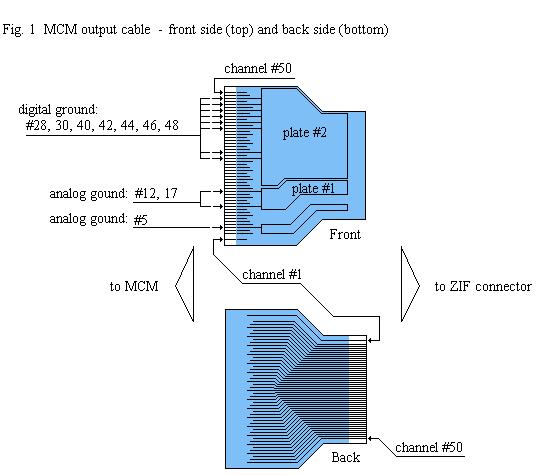

1. Introduction

This note documents the setup of the probe station and the procedure for

the electrical inspection of the 249 final production MCM output cables.

The electrical inspection is conducted after a brief (~ 5 min/cable) visual

inspection which searches for discontinuities. Only output cables

which pass the visual inspection should proceed to the electrical QA test.

2. Setup and Procedure

A handheld multimeter (FLUKE model #8020 B) was used to measure resistance

of traces. Continuity of a trace is assumed to be good when the resistance

reading is less than 0.5 Ohms, and insulation is

assumed to be good when the multimeter gives the overload reading ( > 20

MOhms.

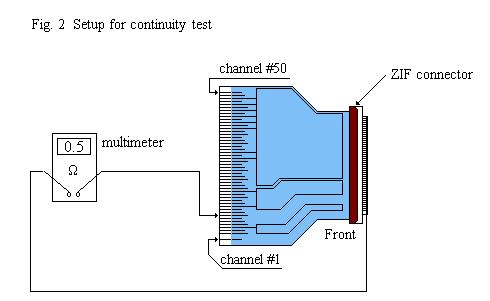

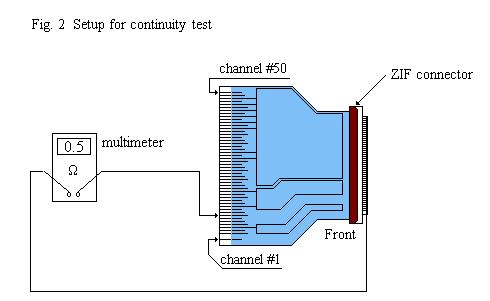

a) Continuity Test

A ZIF connector (1ea Elco 50-contact, .5mm pitch

surface mount horizontal ZIF, 0.4 amp, model #

04-6240-050-003-800) was used to short one end of an MCM output

cable. (All the pins of the connector were soldered together. [Fig.

2] ) The shorted pins were connected to the negative pole of the

multimeter. And the positive pole was connected to a probe which

was used to make a contact to a trace of the output cable one by one to

complete the circuit for good continuity.

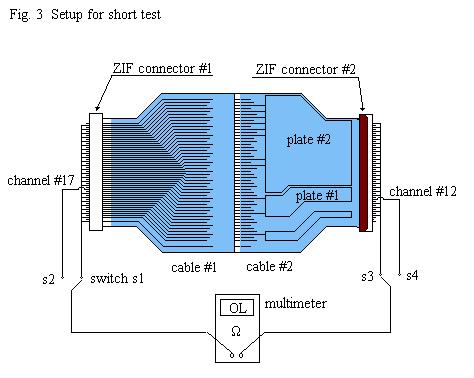

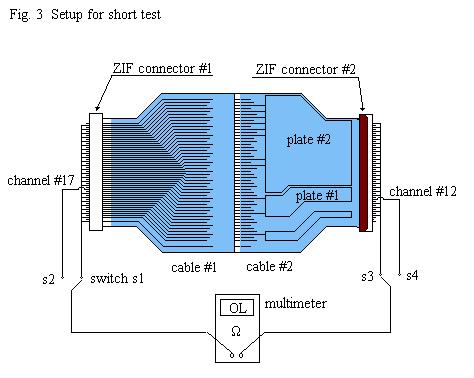

b) Short Test

Two MCM output cables were tested for shorts at

one time. Cable #1 was connected to the connector #1 whose odd numbered

pins were shorted (except pin #17) and cable #2 was connected to the connector

#2 whose even numbered pins were shorted (except pin #12). The pin

#17 in the ZIF connector #1 was extended separately to avoid the short

circuit through the ground plate #2. The pin #12 was extended separately

in the ZIF connector #2 for the same reason. Two cables were pressed

against each other so that each trace of cable #1 made good contact to

the matching trace in cable #2. A set of two cables was tested for

shorts in three different configurations as follows.

Configuration 1: switch #1 - closed,

switch #3 - closed

The test voltage was applied

between the even numbered traces except #12 and the odd numbered traces

except #17.

Configuration 2: switch #2 - closed, switch

#3 - closed

The test voltage was applied between

the even numbered traces and the trace #17 .

Configuration 3: switch #1 - closed, switch

#4 - closed

The test voltage was applied between

the trace #12 and the odd numbered traces.

3. Result

All 249 production MCM output cables were thus tested

and numbered. No discontinuous trace was found among 12201 traces

(= 49 traces * 249 cables). Two cables were found to have shorts.

(cable #1 and #143)

They will not be used in the final assembly of MVD.

Appendix A. MCM to Power Communication (or Daughter)

Board Pin Assignments

MCM Output Cable Connector

(1ea Elco 50-contact, .5mm pitch surface mount horizontal ZIF, 0.4 amp,

model #

04-6240-050-003-800)

1. sil_bias (silicon detector bias)

2. (no connection, no trace)

3. sil_bias_return (silicon bias return)

4. +5V analog, tgv preamp

5. analog gnd, tgv, amu, isum amp

6. ((spare)) (grounded on power-comm board)

7. discr sum out

8. discr sum out gnd

9. +5V analog: comparator

10. analog gnd, comparator

11. +5Vanalog, amu, isum amp

12. analog gnd, tgv, amu, isum amp

13. - 5V analog, isum amp

14. +2.5V, Vmid

15. mcm temp sensor

16. preamp spy

17. analog gnd, tgv, amu, isum amp

18. amu spy

19. serial enable

;SEN

20. read back enable

;RBEN (enables mirror register read back)

21. serial clock

;SCLK (XCLK)

22. serial data in

;SDIN (XDIN)

23. serial data out

;SDOUT (xilinx done when PROG asserted)

24. serial latch

;SLATCH

25. xilinx program

;PROGB (clears FPGA program)

26. mcm_rst

;MCMRST (resets all data registers)

27. +5V, digital, HM & ADC

28. digital gnd, HM & ADC

29. +5V, digital, HM & ADC

30. digital gnd, HM & ADC

31. mode bit 0

32. mode bit 1

33. mode bit 2

34. mode bit 3

35. mode bit 4

36. mode bit 5

37. lvl-1 accept

38. digital gnd

39. mcm_DATA_OUT_clock

;4X Beam Clock

40. digital gnd

41. MCM_DATA_OUT_1

;serial data link #1

42. digital gnd

43. MCM_DATA_OUT_2

;serial data link #2

44. digital gnd

45. 9.5 MHz beam clock

46. digital gnd

47. 38 MHz clock

;4X Beam Clock

48. Digital Gnd

49. PECL clock A

;for ADC

50. PECL clock B

;for ADC

Note: 38 Mbit/sec MCM Data_Out and clock go to LVDS chips which are

mounted on the Power/Communication circuit board and Daughter board.