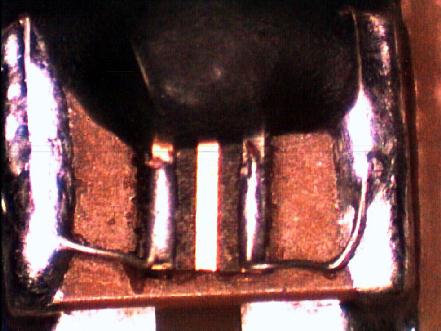

A surface mount cap (yellow) is soldered to a bridge piece (not shown). A kapton tab (brown) with 5 copper/gold strips (white) is glued to the to of the cap. Wires (blue) are soldered from the tab to the cap ends. Wire bonds (black) are bonded to the top half of the strips, and covered with encapsulant (dotted line).

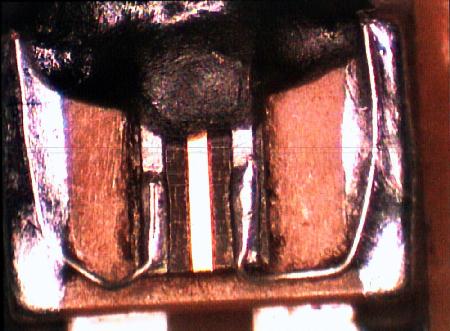

This is an assembly which appears not to be overheated. Note the appearance of the hand-soldered connections.

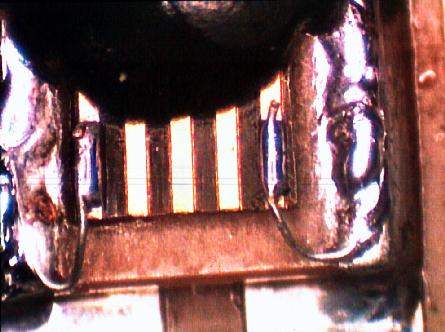

This assembly has discolored PC board (light brown), but the solder has not slumped. The wire bonds are OK.

This is an assembly that has discolored (dark brown and black) PC board on the back. Note the solder has re-melted an slumped down. Also, one of the wire bonds (under the encapsulant) between the tab and the MCM is broken. This could have happened as the cap is no longer firmly attached to the base when the solder is in a liquid state. Movement of the cap floating in solder can break the wirebonds.