- Prepare the box:

- Drill 4 holes in the top for 10-24 rod

- Cut big hole in the bottom. If using saber saw, support the sheet

well, or the welds on the box will shake loose. Alternative: use

dremel tool.

- Fit the extender box. Drill about 18 holes for self-tapping screws, mount

the extender box, and remove it again for now

- Cover up unused holes, move drain hole.

- Put in 5 sides of foam. Cut 0.25" relief pattern for copper tubes,

using the paper template. Cut holes and small funnel shape for

drain pan.

- Put in the lexan air hose output adapters

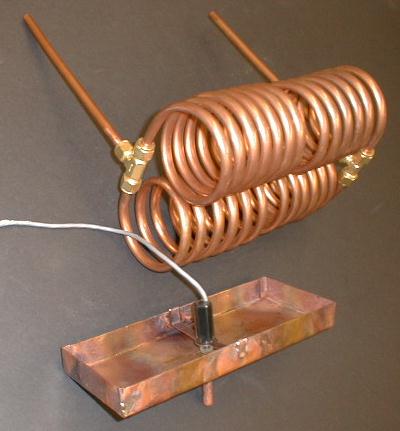

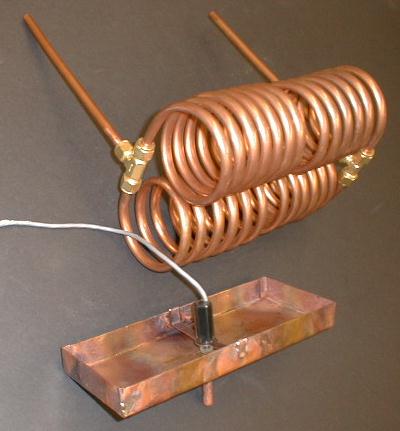

- Assemble and mount drip pan:

- The finished pan is 3.75×10×1" copper sheet; cut extra

0.25" tabs for lap joint at the corners

- Braze the four joints - test for leaks

- Hammer a profile in the bottom using the carved 2x10 block

- Drill a hole in the center, and use a countersink bit to hammer

a funnel shape; drill out to just under 3/8"

- Use countersink to shape the end of a 3-4" piece of 3/8 copper

tubing, hammer into hole

- Braze drain tube in place

- Make a bridge for the level sensor. Strip of copper, 1/4" pipe

thread tap. Folds to go over drip pan edge.

- Braze into place, screw sensor into tapped hole.

- Put drip pan assembly into the box, thread signal cable out.

- Assemble and mount coils:

- trim coil ends and assemble coils and straight pieces with

swagelock (1.25 turns) so that coils fit closely alongside each

other.

- space loops in the bottom coil such that there is space in the

center for the level sensor

- slide coils into the box

- slip on the mounting adapters, screw into place

|