Corrosion in the MVD liquid cooling system

The MVD liquid cooling system cools 3 rows of low-voltage regulator chips

(LDO) on each of the 4 endcap motherboards of the MVD. An aluminum tube (1) is

glued on the board (2) with thermally conducting glue directly opposite of the

LDO chips. Because of the severe mass constraints, and heat conductivity

requirements, aluminum was chosen over copper stainless steel or plastic.

Two short tube stubs, 0.25"OD protrude from the MVD. Custom-made

couplings

fit over these tube ends to make a water-tight connection and to make an

immediate 90° turn; the space available between the tube ends and the

magnet pole face is about 1cm. This is too short for any flexible tubing to

make a 90° turn without folding.

The MVD liquid cooling system cools 3 rows of low-voltage regulator chips

(LDO) on each of the 4 endcap motherboards of the MVD. An aluminum tube (1) is

glued on the board (2) with thermally conducting glue directly opposite of the

LDO chips. Because of the severe mass constraints, and heat conductivity

requirements, aluminum was chosen over copper stainless steel or plastic.

Two short tube stubs, 0.25"OD protrude from the MVD. Custom-made

couplings

fit over these tube ends to make a water-tight connection and to make an

immediate 90° turn; the space available between the tube ends and the

magnet pole face is about 1cm. This is too short for any flexible tubing to

make a 90° turn without folding.

The cooling circuit is a closed-loop,

no-pressure system, consisting of a

circulating pump, a heat exchanger, a can to trap air bubbles, and an air

bubble exhaust line. The plumbing is done in copper and flexible plastic

tubing.

postscript

|

The design calls for FC75 (1,

2,

3)

as the cooling liquid. This is a non-conductive,

non-corrosive liquid made for cooling electronics. However, the heat capacity

is about half of that of water. Also, any spill is a chemical spill incident.

The MVD is located about 5m above the pump-heat exchanger assembly, so filling

and priming the system without spills is not trivial.

Therefore, we would run the system initially with ordinary water, and after

no-spill filling procedures were worked out, we would do the paperwork and

switch to FC75.

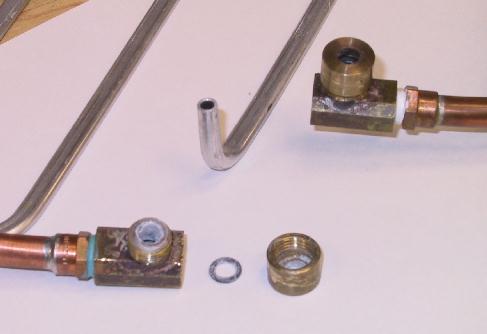

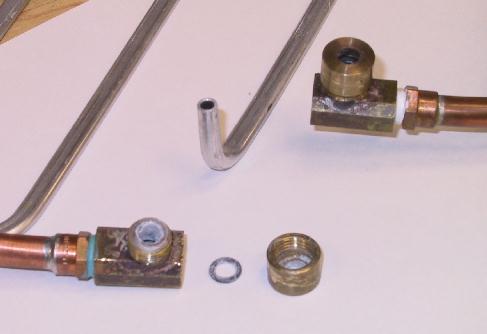

The custom couplings that connect the cooling tube to the supply and return

lines consisted of a a 90° piece, with a threaded part,

over which a cap can be screwed. These parts were made of brass. The aluminum

tube fits loosely through the cap and into the 90° piece. A small

O-ring gets compressed between the thread and the bottom of the cap, providing

a seal. In the picture, one such fitting is shown disassembled, one is

assembled, and a spare cooling tube is also shown.

The custom couplings that connect the cooling tube to the supply and return

lines consisted of a a 90° piece, with a threaded part,

over which a cap can be screwed. These parts were made of brass. The aluminum

tube fits loosely through the cap and into the 90° piece. A small

O-ring gets compressed between the thread and the bottom of the cap, providing

a seal. In the picture, one such fitting is shown disassembled, one is

assembled, and a spare cooling tube is also shown.

bigger -->

|

On November 26, work started in the hall in order to mount the NTC counters,

which would fit between the MVD and the pole face. Some of the work involved

replacing the couplings with different ones, which would be less prone to leaks

during installation - the little O-rings had given us trouble in the past.

Also, the couplings and tubes needed to be rearranged to clear the NTC. It

became apparent that some of the couplings had become frozen to the aluminum

tubes. Only with considerable effort could all the couplings be removed. They

had become welded together with oxides or other compounds (white, gray, black,

green). Some of this is visible in the photo above. Clearly these

encrustations had kept the system solid and leakproof, but cleaning this stuff

off showed that a lot of the aluminum had been eaten away.

(all photos)

Obviously, this was caused by galvanic corrosion between the aluminum tube and

the brass coupling. They were probably touching, or at least very close in all 8

locations (one supply and one return per quadant).

A measurement of the resistivity of a sample of the water retrieved from the

system was ~150 micromhos/cm. A sample of the local tap water tested at 100

micromhos/cm.

The new fittings were actually able to take care of the holes that are visible

in the photos. Two quadrants were reconnected and were not leaking when water

circulation was turned oback n.

What is not visible in these photographs is that in two locations,

a hole was found at the point where the tube enters the MVD, and there is

nothing that can be done to fix that on a short time scale. Thus two quadrant

could not be operated.

With half of the MVD out of commission, and the remaining tubing in unknown

condition, and perhaps not able to withstand the jostling of the NTC

installation plus 2 months of running, it was decided to pull the detector out.

We will remanufacture the cooling tubes in copper, and we will have copper and plastic

couplings. Also we need to replace the water with FC75 or propylene

glycol/water mixture (already in use for the DC alcohol bath), or another

liquid that prevents corrosion.

Assembly procedures (a subset):

Last update 30 Nov 2001 -HvH

back

The MVD liquid cooling system cools 3 rows of low-voltage regulator chips

(LDO) on each of the 4 endcap motherboards of the MVD. An aluminum tube (1) is

glued on the board (2) with thermally conducting glue directly opposite of the

LDO chips. Because of the severe mass constraints, and heat conductivity

requirements, aluminum was chosen over copper stainless steel or plastic.

Two short tube stubs, 0.25"OD protrude from the MVD. Custom-made

couplings

fit over these tube ends to make a water-tight connection and to make an

immediate 90° turn; the space available between the tube ends and the

magnet pole face is about 1cm. This is too short for any flexible tubing to

make a 90° turn without folding.

The MVD liquid cooling system cools 3 rows of low-voltage regulator chips

(LDO) on each of the 4 endcap motherboards of the MVD. An aluminum tube (1) is

glued on the board (2) with thermally conducting glue directly opposite of the

LDO chips. Because of the severe mass constraints, and heat conductivity

requirements, aluminum was chosen over copper stainless steel or plastic.

Two short tube stubs, 0.25"OD protrude from the MVD. Custom-made

couplings

fit over these tube ends to make a water-tight connection and to make an

immediate 90° turn; the space available between the tube ends and the

magnet pole face is about 1cm. This is too short for any flexible tubing to

make a 90° turn without folding.

The custom couplings that connect the cooling tube to the supply and return

lines consisted of a a 90° piece, with a threaded part,

over which a cap can be screwed. These parts were made of brass. The aluminum

tube fits loosely through the cap and into the 90° piece. A small

O-ring gets compressed between the thread and the bottom of the cap, providing

a seal. In the picture, one such fitting is shown disassembled, one is

assembled, and a spare cooling tube is also shown.

The custom couplings that connect the cooling tube to the supply and return

lines consisted of a a 90° piece, with a threaded part,

over which a cap can be screwed. These parts were made of brass. The aluminum

tube fits loosely through the cap and into the 90° piece. A small

O-ring gets compressed between the thread and the bottom of the cap, providing

a seal. In the picture, one such fitting is shown disassembled, one is

assembled, and a spare cooling tube is also shown.