ps

ps ps

ps

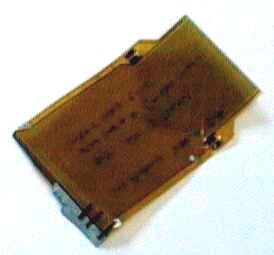

In B is the same assembly, rotated so that the strips are now oriented horizontally.

In C, the Kapton cable is folded over the top of the Silicon to the left. The location of the fold is indicated by the arrows in B and C. We are looking at the back of the Kapton, MCM and output cable.

In D, the cable is folded at 45° such that the cable points down again, and is again face up. The assembly is now 5 cm shorter than in A.

ps

ps

We have glued up some silicon with kapton, and are looking at the folding and mounting procedures.

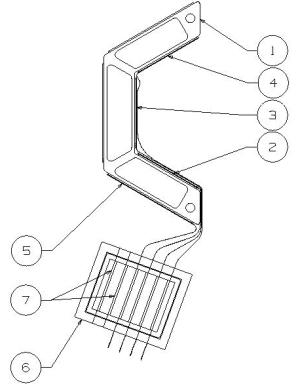

4.2) Is the cable long enough? To first order, the length of cable 'used up' by the folding process is a

square

of 52 mm. Recall that we start with an 'inner-top' detector assembly, (4) in the figure below, and want to do the

folding and then place the silicon in the 'inner-middle' position, (3) in the figure. However, there are at least

2 additional length penalties: the first is the gentle bend that the IT cable takes between (3) and (2), and the

fact that the IT MCM position is the rightmost one in the plenum, whereas the IM sits 6mm further to the left.

In Jan's 3-D model the sum of these effects is that the IT cable is 2 mm too short if

the MCM is in the IM slot. However, if the IT position is not occupied, then there would

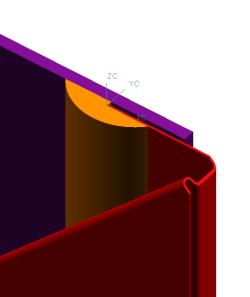

be no problem. The modeling also showed that in the location where the two folds meet, a

notch needs to be cut out of the cable's edge, as can be seen in the renderings.

| This is what happens if you carefully try to fold the cable close to the silicon. The silicon does not survive this, and also delaminates from the kapton. |

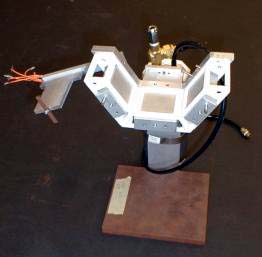

| Toshi Shiina took the problem as a challenge, and with his intimate knowledge of our silicon assembly systems, many of which he helped design and build, and his superb craftsmanship, has come up with specialized jigs and tools with which we can, in principle, so far, do the job. |

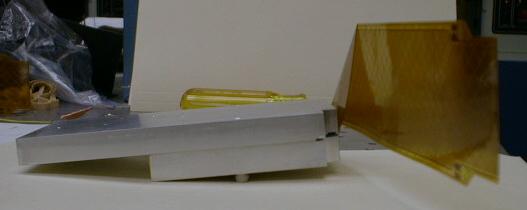

| This jig has 1/2mm-wide jaws to hold the kapton close to the silicon. The silicon itself is protected in a well behind the jaws. This allows one to fold the kapton 90° within 1 mm of the silicon edge, without putting any stress on the silicon itself. |

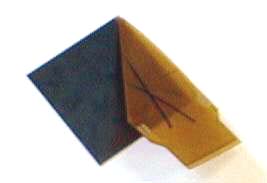

| This is a test assembly where the kapton was folded using this jig. Note the silicon is unbroken. |

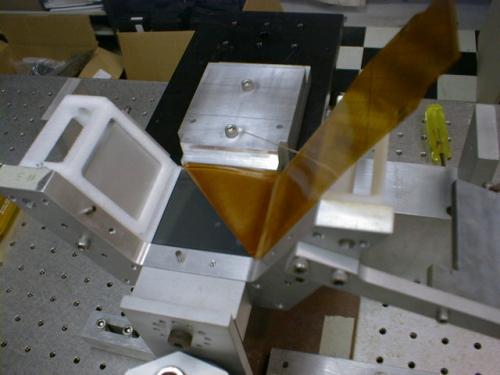

| This shows the mounting fixture, with heavy blocks holding a C-cage. Various vacuum pickup fixtures need to be modified to handle the rotated silicon, with the folded cable (90°) attached. |