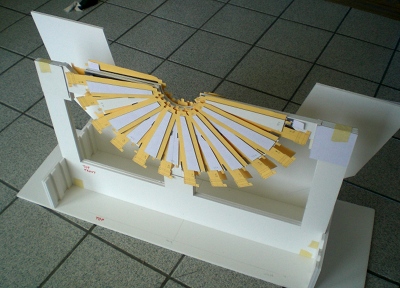

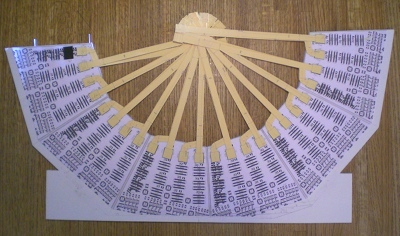

| Station 2. You can see the modules in 4 layers,

2 front and 2 back. The modules are detachable. The HDIs have

not yet been bent.

Click to enlarge→

|

|

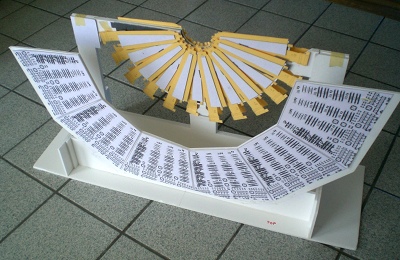

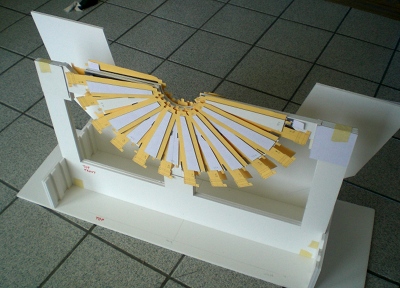

| Station 2 mounted in the stand. The back plane is the

central part of the big wheel.

Click to enlarge→

|

|

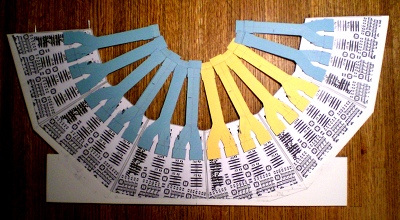

| View from the back, showing the ROCs.Only the inner

part of the boards, where the connectors are located, is represented.

Click to enlarge→

|

|

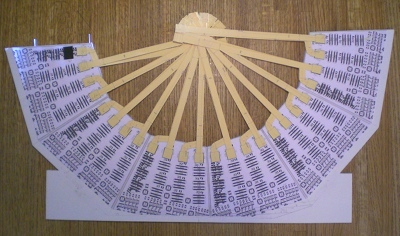

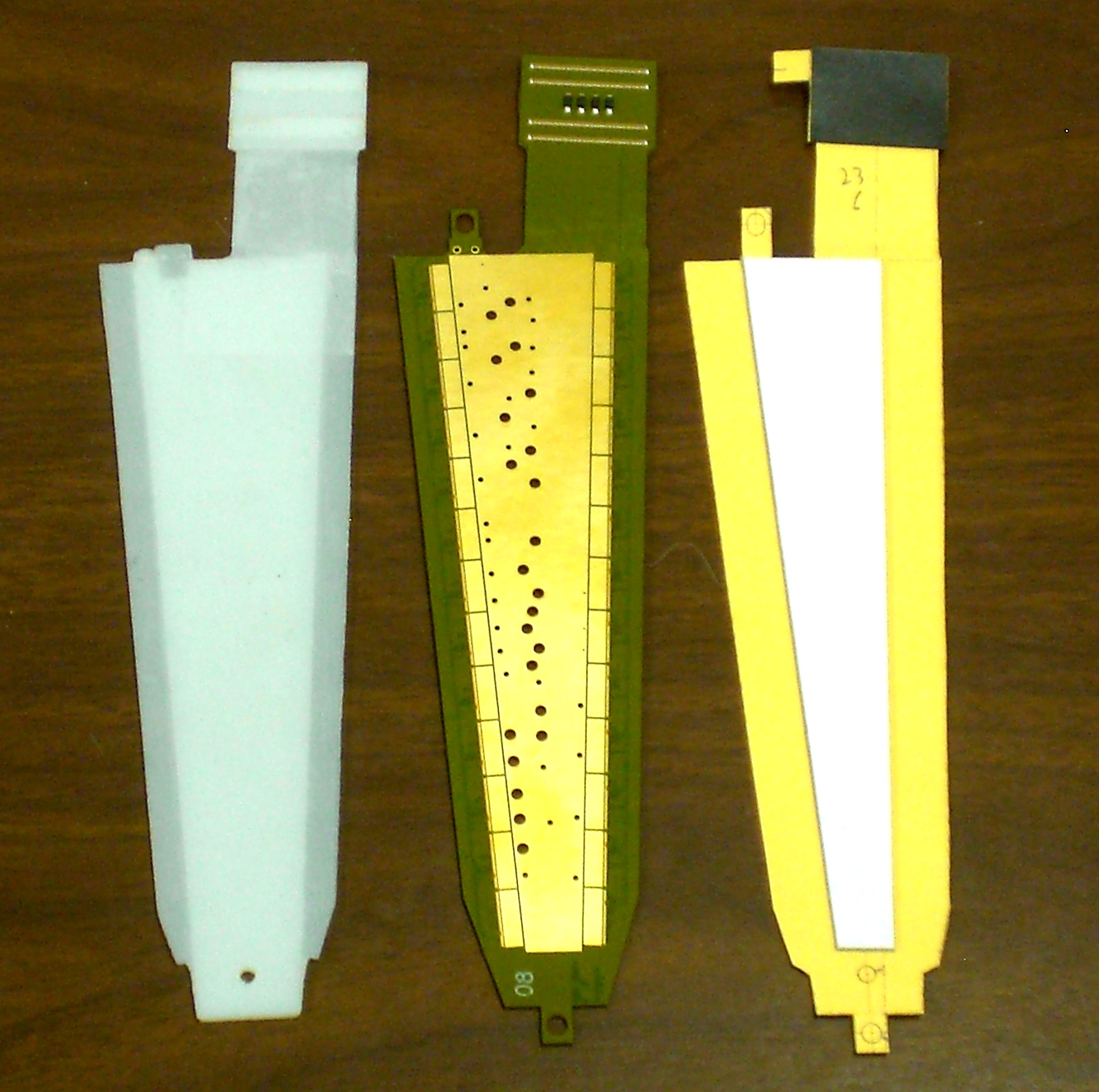

| This is the ROC board, with the station-1 cables attached, before

they are bent. On the top left, a station-2 connector pair is

modeled with refrigerator-magnet material.

Click to enlarge→

|

|

| This is the ROC board, with the station-2 cables attached, before

they are bent.

Click to enlarge→

|

|

| View of the corner of station 1, with bent cables attached.

Click to enlarge→

|

|

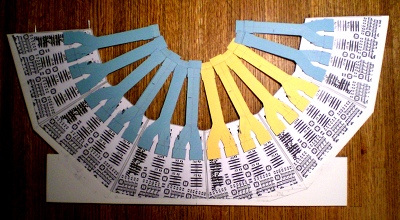

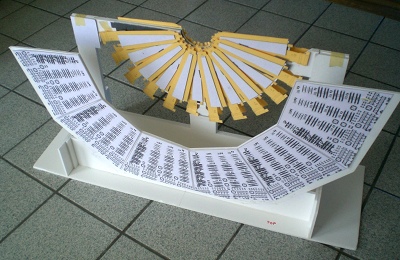

| Station 1, 2 and the ROC boards

Click to enlarge→

|

|

| Station 1, 2 and the ROC boards

Click to enlarge→

|

|

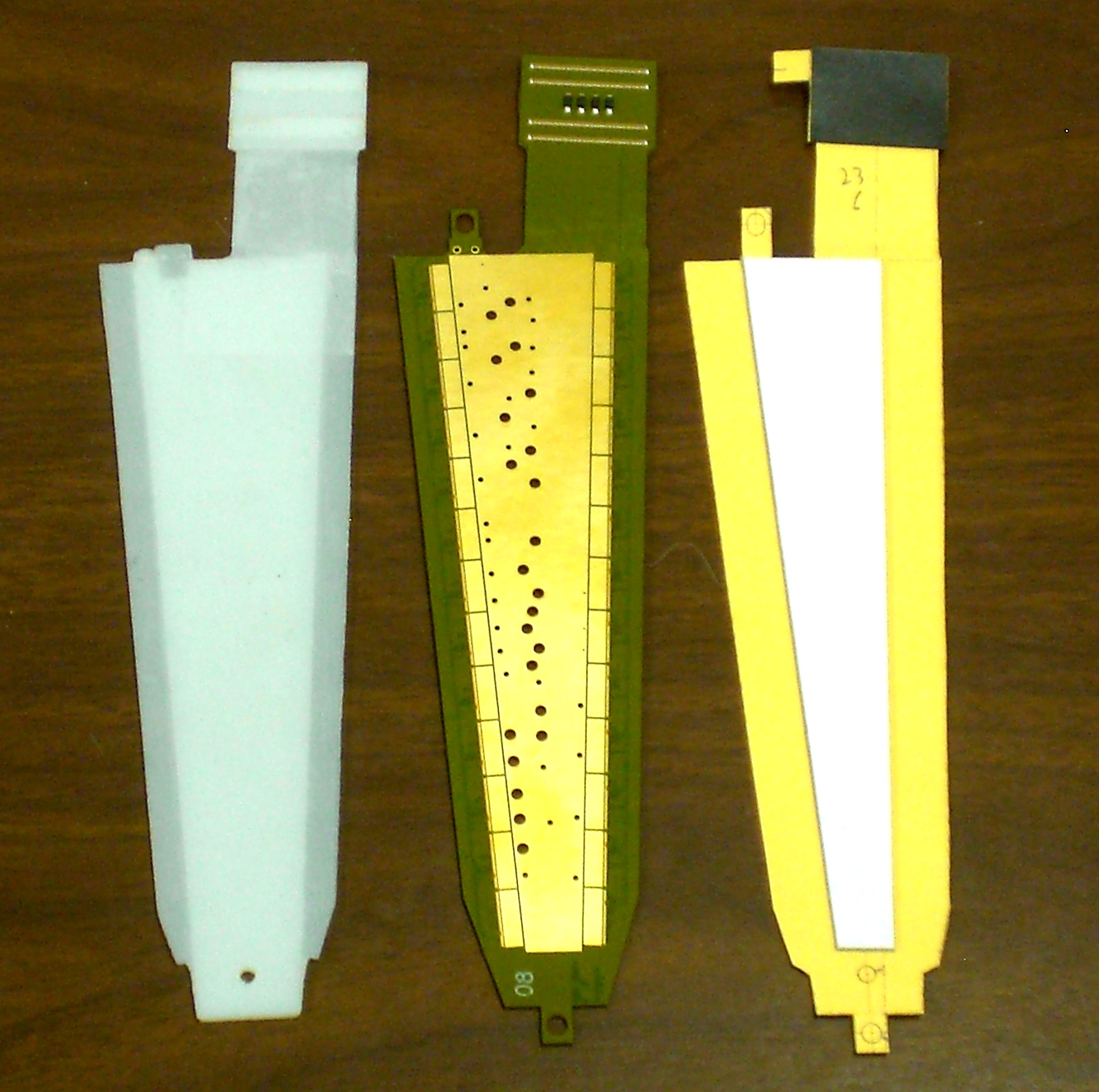

| One detector module, as a rapid-prototype, an HDI prototype

and a paper-and cardboard version.

Click to enlarge→

|

|

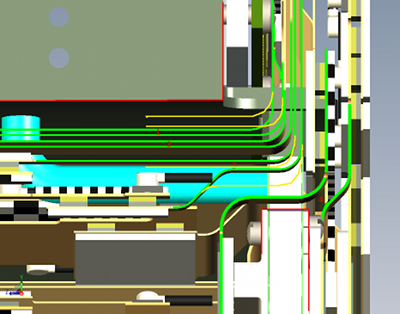

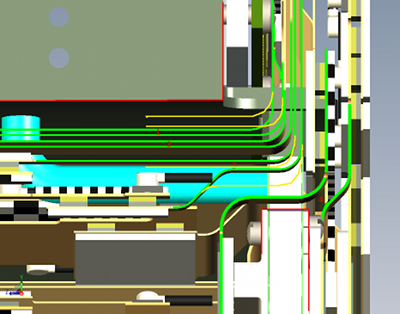

Of all assembly procedures, the bending of the HDIs and the

extension cables likely will have the largest errors/tolerances.

The cables are very stiff.

The most critical bends are in the extension cables (shown in green)

where they approach the

big wheel, and make a 90° turn from running in the z-direction to

going radially out to their connector attachments. Eight cables are nested as

they make this turn. In the current model, there is ~0.5 mm space between

adjacent cables. If the bend locations are off by more than this, it could

prevent a cable from reaching its connector.

The space available in this region is between the edge of the cage, and

the edge of the station-4 support board, both outlined in red. The radial

distance is about 16 mm. If we bend the cables in slightly different

locations (sketched in yellow), we can increase the inter-cable space

to 1-2 mm. To first order, the length of the cables remains the same.

Click to enlarge→

|

|