|

Fernando Garzon Ph D, F.E.C.S

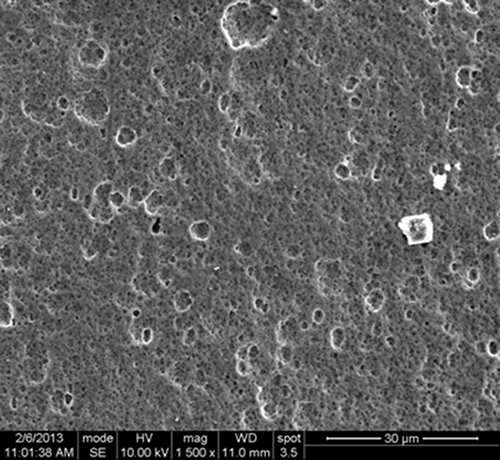

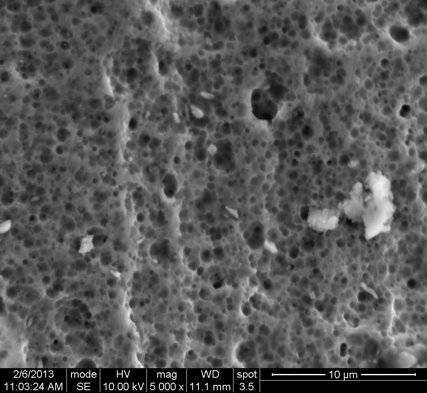

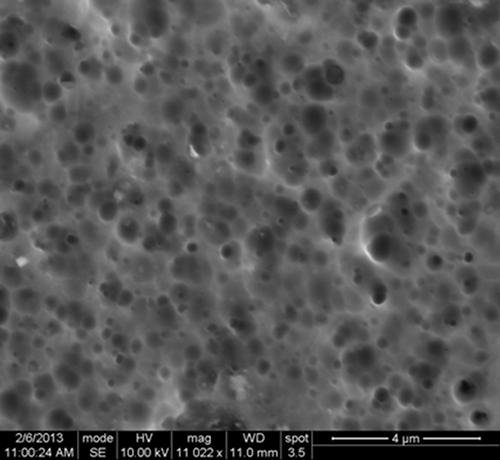

President of The Electrochemical Society: Attached is the SEM EDX (explanation) analysis of the cooling channel. As you can see the material is deeply pitted by galvanic corrosion. X-ray spectroscopy also detected the presence of silver. Perhaps silver filled high thermal conductivity epoxy was used in the construction? In any case it appears to be a pretty straight forward case of galvanic corrosion between the dissimilar components in electronic contact with each other and a wet environment. [Silver eopxy is indeed used, between the tube bend and the Aluminum end block, grounding the tube and the carbon foam]. |

|

Wed Feb 06 22:32:41 2013

Filter Fit Chi-squared value: 24.711 Errors:+/-1 Sigma

Correction Method: Proza (Phi-Rho-Z)

Acc.Voltage: 10.0 kV Take Off Angle: 37.1 deg

Element Element Wt.% Atom % Atom %

Line Wt.% Error Error

C K 1.67 +/-0.03 3.74 +/- 0.06

O K 0.73 +/-0.03 1.23 +/- 0.05

Al K 94.31 +/-0.34 94.21 +/- 0.34

Ag L 3.30 +/-0.11 0.82 +/- 0.03

------------- --------------

Total 100.00 100.00

|

|

| xxx |

|

Hubert Van Hecke Last modified: Thu Feb 7 19:27:09 EST 2013