| Sat 19 January 2013

Stave xxx-01 is one of the bad leakers, though we were not

able to precisely pinpoint the location.

I milled away the carbon face sheet, you can see some of

the thin foam remaining on the tube on the right of the worked area.

Then I milled away the top surface of the Al tube, and cleaned the burrs.

The inside surfaces are pristine, no marks of any kind.

|

| | A picture taken through Sal's microscope also does not reveal

any more details. (The two green spots on the left are markers in the

microscope optics).

|

|

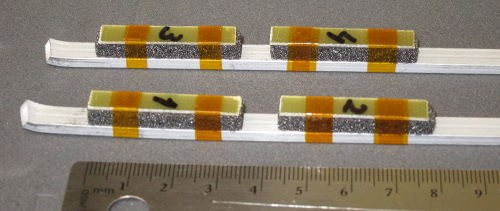

| I cut 4 pieces of the carbon foam, and 4 pieces of G4, and

assembled 4 Aluminum-Carbon sandwiches. I used one of the tubes from

LBL, not the new straight tubes we bought.

|

|

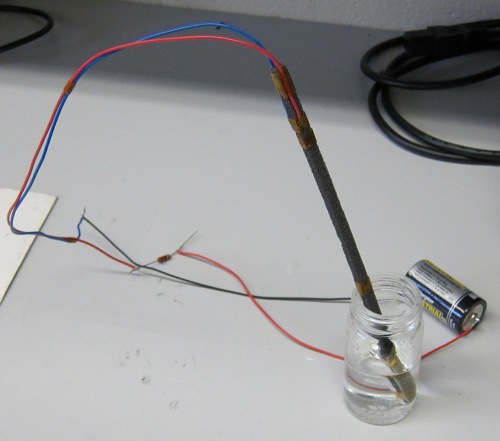

| I immersed the assemblies in tap water. Start time Sat 19 January 2013, 13:00.

We have to decide when to remove each of the samples (Perhaps 1st in 1 week, 2nd in 2 weeks,

3rd in 4 weeks, 4th in 8 weeks).

|

|

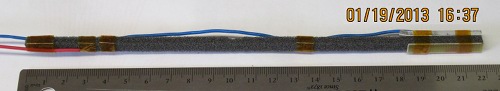

| In order to speed up the corrosion, Walter suggested to pass a current trough the

Al-C interface. So I made a sansdwich of a carbon foam stick with a piece of Al tube,

|

|

I hooked up 2 versions, with a 24 ohm resistor in series with a 1.5 V battery:

- +1.5V connected to the carbon - Start 16:00, initial current 45.7 mA.

- +1.5V connected to the Al - Start 16:30, initial current 42.5 mA)

|

|

|

On Tuesday, the currents were still roughly the same, but whitish

stuff had appeared at the carbon/Al interface. This is very weak stuff,

which detaches and floats to the bottom when the fluid moves a little.

|

|