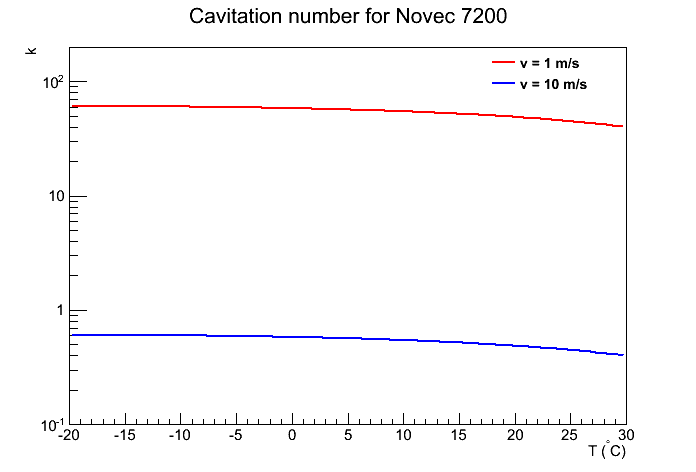

const Double_t pressure = 48263.3011; // 7 psi

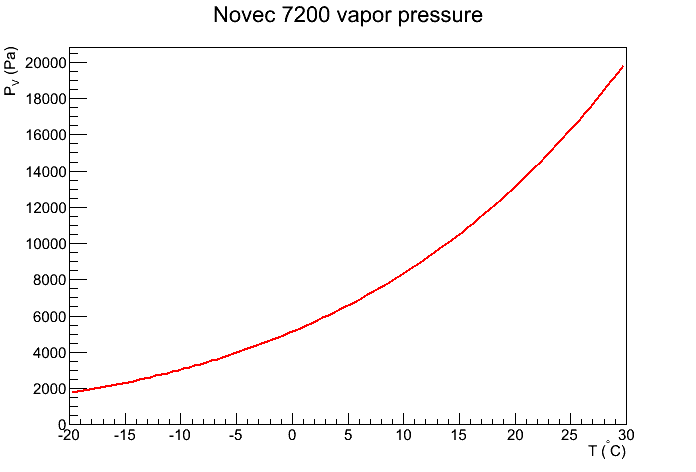

Double_t vapor( Double_t *t, Double_t *par = NULL )

{

// vapor pressure in Pa

Double_t tt = t[0];

// cout << "vapor T: " << tt << endl;

return TMath::Exp( 22.289 - (3752.1/(tt+273.0)) );

}

Double_t density( Double_t *t, Double_t *par = NULL )

{

// density in g/ml to kg/m^3

Double_t tt = t[0];

Double_t rho = 1.4811 - 0.0023026*tt;

// cout << "density T: " << tt << endl;

return 1000.0*rho;

}

Double_t cavitation( Double_t *t, Double_t *par )

{

Double_t tt = t[0];

Double_t p = par[0];

Double_t v = par[1];

cout << "p: " << p << " v: " << v << " T: " << tt

<< " vapor pressure: " << vapor(t)

<< " density: " << density(t) << endl;

Double_t k;

k = 2.0*(p - vapor( t ) )/(density( t )*TMath::Power(v,2));

return k;

}

Int_t drawvapor ( void )

{

TF1 *p;

p = new TF1( "p", vapor, -20.0, 30.0, 0 );

p->SetTitle("Novec 7200 vapor pressure");

p->GetXaxis()->SetTitle("T (^{#circ}C)");

p->GetYaxis()->SetTitle("P_{V} (Pa)");

p->GetYaxis()->SetTitleOffset( 1.5 );

p->Draw();

return 0;

}

Int_t drawk ( void )

{

TLegend *leg = new TLegend( 0.7, 0.8, 0.89, 0.89 );

leg->SetFillColor(0);

leg->SetBorderSize(0);

TF1 *k;

k = new TF1( "k", cavitation, -20.0, 30.0, 2 );

k->SetTitle("Cavitation number for Novec 7200");

k->SetParameter( 0, pressure );

k->SetParameter( 1, 1.0 );

k->SetLineColor( kRed );

leg->AddEntry( k, "v = 1 m/s", "L" );

k->Draw();

TF1 *kk;

kk = new TF1( "kk", cavitation, -20.0, 30.0, 2 );

kk->SetLineColor( kBlue );

kk->SetParameter( 0, pressure );

kk->SetParameter( 1, 10.0 );

leg->AddEntry( kk, "v = 10 m/s", "L" );

kk->Draw("same");

k->GetXaxis()->SetTitle("T (^{#circ}C)");

k->GetYaxis()->SetTitle("k");

k->GetYaxis()->SetRangeUser(0.1,200.0);

leg->Draw();

return 0;

}

Followup from ROB:

Some system specs for now just to put them out there. Delta P across all staves in loop 24psi (input is 24psi. output at detector is very close to Zero) Head pressure from the Manifold to the detector is reading around 7-8psi which is about what we see when we are flowing. I'm putting in a gauge tomorrow to get a real number. Staves are hooked up as follows, 2 staves in parallel. That pair is in series with another pair that is in parallel. So is if every stave is the same, the pressure drop of the first pair should be from 24psi to 12psi, the second pair should be 12psi to almost zero. Flow rates. Typically we are flowing a total of around 20gph through the loop. Since we split the flow, each stave sees around 10 gph. The Al tubing is 5mm by 10mm. From that, if I did it right, the velocity is 0.21m/s. This is the average velocity in the Al tube. The fluid accelerates when it leaves the first pair of staves and travels in the 1/8" OD tube and whenever it enter and exits a stave. John, can you put that velocity into your macro and see that that looks like. Rob