Flow tests

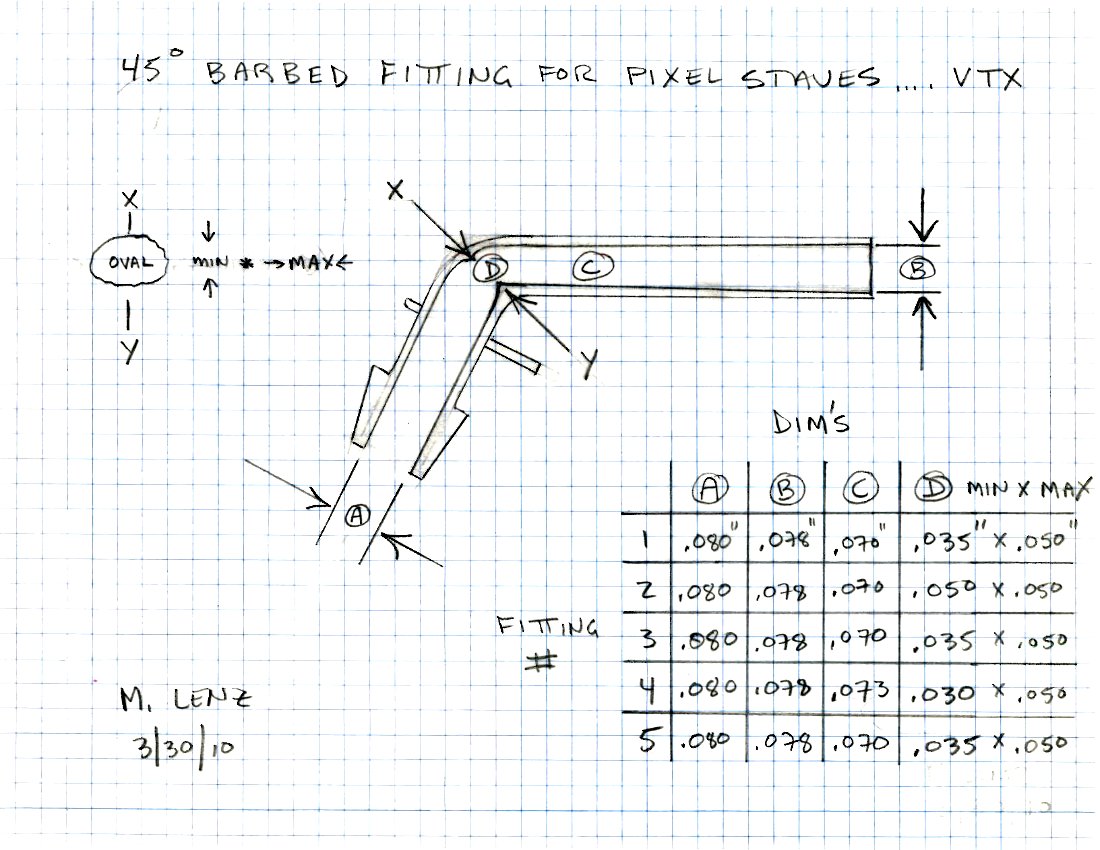

Cooling fluid enters the VTX barrel omega pieces through plastic inserts which

are glued into the omega pieces, make a 45° bend and have a hose barb on

the outside. The target flow rate is 22 cc/second. The cooling fluid is

3M HFE 7200,

which has a viscosity 0.6 times that of water.

The inner diameter of the channel through this connector piece is 2mm, the

smallest channel by far in the system, dominating the flow resistance.

The staves are mocked up with a 20-cm piece of 3/16" ID hose. Two connectors

are glued back-to back, so they form a circular cross section, and the pair

is glued into the hose. One of each pair is plugged with a toothpick. Five

of these 'staves' are daisy-chained together.

Effect of viscosity and density

|

Earlier we had done a simpler test by mounting a single connector at the

bottom of a 1/2" ID vertical tube, which had a funnel on top,

and by timing how long it took to fill a

2-liter measuring cup. We did this both for water and HFE 7200. The column

height (top of fluid in the funnel to the entry into the connector) was

138 cm.

Water:

-----------------

liters time

-----------------

1.0 3m 41s 221s

1.5 5m 50s 350s 129

2.0 7m 40s 460s 110 avg 120sec/500cc = 4.17 cc/sec

HFE 7200:

-----------------

liters time

-----------------

0.5 1m 44s 104s

0.5 1m 45s 105s

1.0 3m 33s 213s 108

1.5 5m 29s 329s 116 avg 112sec/500cc = 4.46 cc/sec

Since the HFE has density 1.42, and viscosity 0.6, we had expected

the HFE times to be 2.4 times faster. We saw only a 7% decrease in time.

Here is the explanation by Don:

Pressure drop is affected by changes in viscosity and density, but the

pressure drop is comprised of frictional pressure drop, which is a function

of both viscosity and density, and inertial pressure drop (pressure drop due

to changes in flow as in elbows and fittings), which is a function of density

only. Viscosity is greatly affected by temperature differences but density

is only mildly affected by temperature.

|

|

|

Why is the flow so low?

|

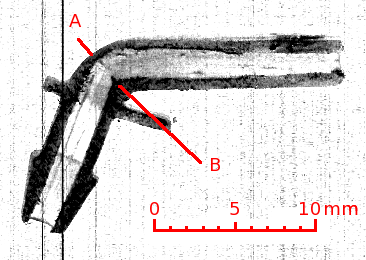

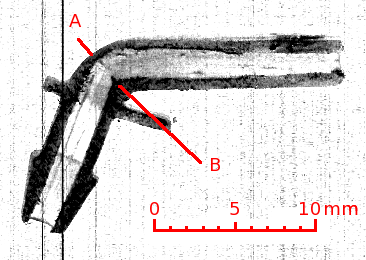

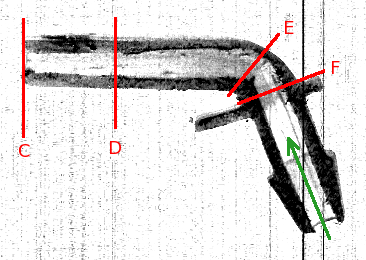

| I sanded a barb down to the midplane, and made this image

(400% on the copymachine, scan, invert colors). You can see that the outer

radius of the channel curves (A), but the inner radius does not curve. In

addition, there appears to be a ridge, or thin wall, in line with the red

line AB, which further constricts the channel at the bend. You can feel this

wall with the tip of a needle. When I cut another barb just below AB, the

opening in this plane could be seen. It is approximately a

1mm × 1.5mm

oval.

|

|

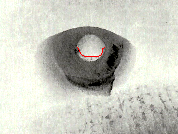

| In this picture of the cross section I tried to indicate

the edge of the obstruction in red.

|

|

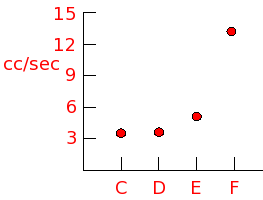

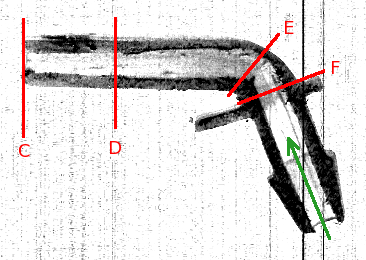

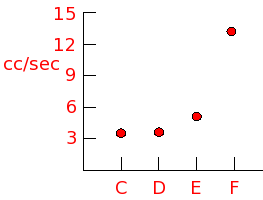

I did 4 runs where I progressively cut off more and

more from the barb, as indicated on the photo:

C no cut 3.8 cc/sec

D cut halfway the inserted section 3.7 cc/sec

E cut just downstream of the obstruction 5.0 cc/sec

F cut just below the flange 13.5 cc/sec

(raw data below)

|

|

|

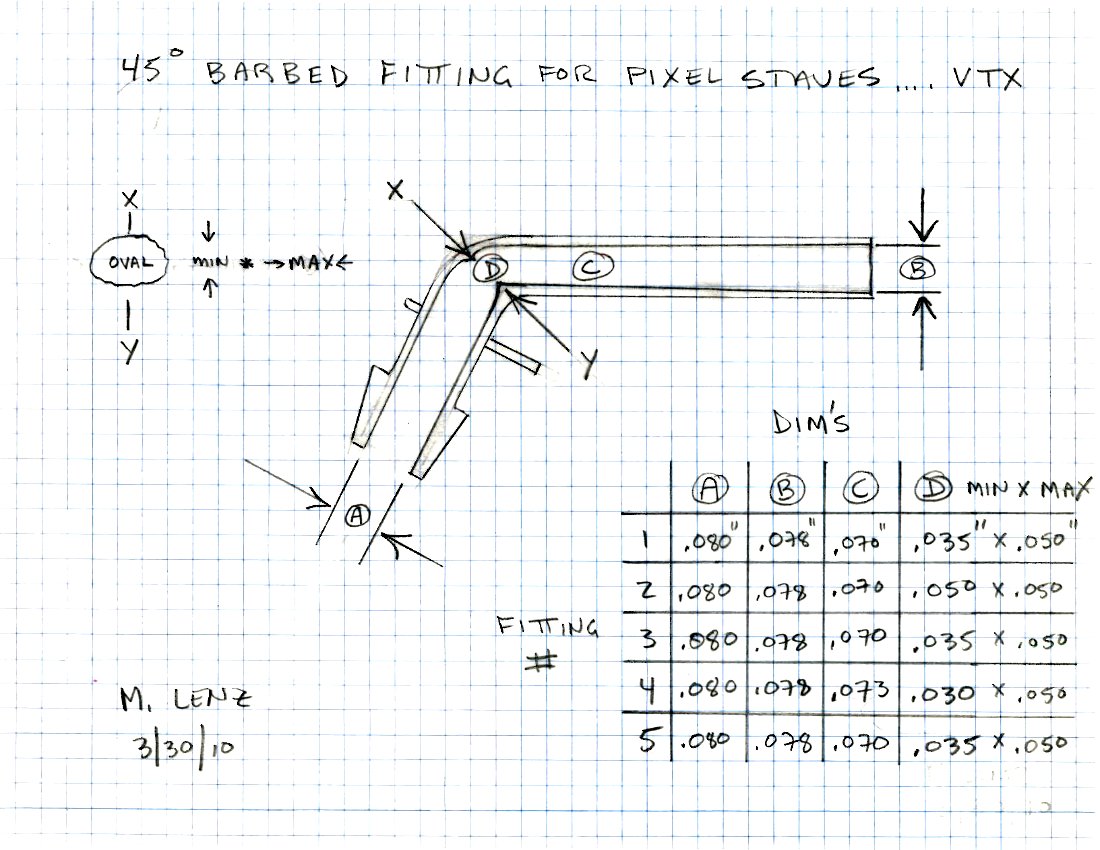

Also see a ppt of a photo by Mike Lenz

from 29 Mar 2010.

bigger →

(I enhanced the contrast)

|

|

|

Mike also sectioned and measured some barbs

bigger →

|

|

|

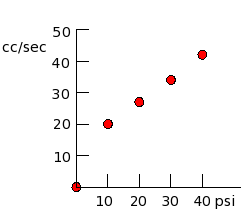

Flow test with Stripixel stave

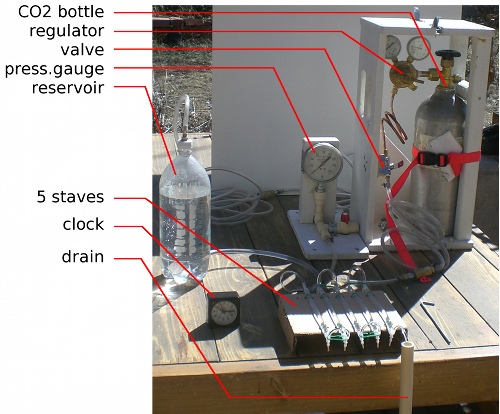

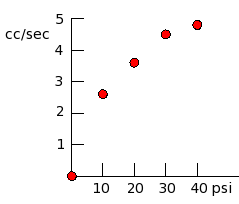

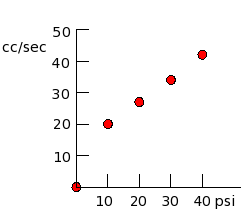

Using the CO2 rig shown on top, I measured flow through a stripixel stave,

for pressures between 10-40 psi.

press. flow

-------------------

10 psi 19.6 cc/sec

20 27.0

30 33.7

40 42.3

-------------------

This stave is 39.5×3.6×0.5 mm

|

|

Raw data:

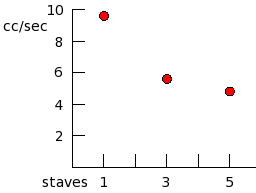

5 staves 30 psi

-------------------------------------

liters min:sec, seconds from 0

run 1 run 2 run 3

--------- --------- ---------

0.0 0:05 000 0:29 000 0:05 000

0.1 0:29 024 0:51 022 0:26 021

0.2 0:50 045 1:12 043 0:50 045

0.3 1:11 066 1:34 065 1:11 056

0.4 1:35 090 1:57 088 1:33 088

0.5 1:57 105 2:19 110 1:55 110

0.6 2:19 134 2:41 132 2:17 132

0.7 2:42 157 3:01 152 2:29 144

0.8 3:04 179 3:26 177 3:02 177

0.9 3:29 204 3:51 202 3:27 197

1.0 3:49 224 4:11 226 3:47 222 4.5 cc/sec = 0.27 l/min

5 staves 20 psi

--------------------------

l min:sec

run 1 run 2

--------- ---------

0.0 0:26 000 0:01 000

0.1 0:53 027 0:28 027

0.2 1:20 054 0:55 054

0.3 1:47 081 1:23 082

0.4 2:16 110 1:51 110

0.5 2:42 136 2:17 136

0.6 3:09 163 2:45 164

0.7 3:37 191 3:12 191

0.8 4:05 219 3:40 219

0.9 4:35 249 4:10 249

1.0 5:00 274 4:36 275 3.6 cc/sec = 0.22 l/min

5 staves 10 psi

--------------------------

l min:sec

run 1 run 2

--------- ---------

0.0 0:12 000 0:40 000

0.1 0:51 039 0:-- ---

0.2 1:29 077 1:55 075

0.3 2:09 117 2:34 114

0.4 2:48 156 3:14 154

0.5 3:26 194 3:52 192

0.6 0:-- --- 4:30 230

0.7 4:45 273 5:09 269

0.8 5:22 310 5:47 307

0.9 6:07 355 6:31 351

1.0 6:42 390 7:07 387 2.6 cc/sec = 0.15 l/min

5 staves 40 psi

--------------------------

l min:sec

run 1 run 2

--------- ---------

0.0 ---- --- 0:05 000

0.1 0:07 000 0:26 021

0.2 0:26 019 0:50 045

0.3 0:45 038 1:11 056

0.4 1:05 058 1:33 088

0.5 1:24 077 1:55 110

0.6 1:43 096 2:17 132

0.7 2:02 115 2:29 144

0.8 2:22 135 3:02 177

0.9 2:44 157 3:27 202

1.0 3:01 174 3:47 222 4.8 cc/sec = 0.29 l/min

3 staves 30 psi

--------------------------

l min:sec

run 1 run 2

--------- ---------

0.0 0:52 000 0:27 000

0.1 1.08 016 0:44 017

0.2 1.25 033 1:01 034

0.3 1.43 051 1:19 052

0.4 2.00 068 1:36 069

0.5 2.17 085 1:53 086

0.6 2.34 102 2:11 101

0.7 2.51 119 2:28 121

0.8 3.01 129 2:45 138

0.9 3.28 156 3:05 158

1.0 3.44 172 3:21 174 5.7 cc/sec = 0.35 l/min

1 staves 30 psi

--------------------------

l min:sec

run 1 run 2

--------- ---------

0.0 0:31 000 0:09 000

0.1 0:42 011 0:19 010

0.2 0:50 019 0:29 020

0.3 1:01 030 0:39 030

0.4 1:12 041 0:50 041

0.5 1:22 051 1:00 051

0.6 1:33 062 1:11 062

0.7 1:43 072 1:21 072

0.8 1:53 082 1:31 082

0.9 2:05 094 1:42 093

1.0 2:14 103 1:52 103 9.7 cc/sec = 0.58 l/min

barb connector full length

----------------------------------

ltr run 1 delta t run 2 delta t

-------------- -------------

0.5 15:44:57 - 15:56:50

1.0 47:10 133 59:10 140

1.5 49:30 144 01:25 135

2.0 51:33 122 03:35 130 266 sec/liter = 3.76 cc/sec

barb connector 5.5mm cut off

----------------------------------

ltr run 1 delta t

--------------

0.5 16:09:09 -

1.0 11:28 139

1.5 13:38 135

2.0 15:53 130 268 sec/liter = 3.73 cc/sec

barb connector cut after bend

----------------------------------

ltr run 2 delta t run 1 delta t

-------------- -------------

0.5 16:40:50 - 16:33:00

1.0 42:27 97 34:50 110

1.5 44:06 99 36:16 86

2.0 45:45 99 38:06 110 200 sec/liter = 5.0 cc/sec

barb connector cut in front of bend

----------------------------------

ltr run 1 delta t run 2 delta t

-------------- -------------

0.5 16:57:55 - 16:57:00

1.0 58:30 35 16:58:38 38

1.5 59:10 40 16:59:12 34

2.0 59:47 37 16:59:50 38 74sec/liter = 13.5 cc/sec

Stripixel stave:

stripixel stave 10 psi

--------------------------

l sec

run 1 run 2

----- -----

0.0 43 53

0.1 48 5 58 5

0.2 53 5 02 4

0.3 58 5 08 6

0.4 03 5 13 5

0.5 08 5 18 5

0.6 13 5 23 5

0.7 18 5 28 5

0.8 23 5 33 5

0.9 29 6 40 7

1.0 34 5 44 4 avg 5.1 sec/100cc = 51 sec/l = 19.6 cc/sec

stripixel stave 20 psi

--------------------------

l sec

run 1 run 2 run 3

----- ----- -----

0.0 07 23 30

0.2 14 7 31 8 38 8

0.4 22 8 38 7 45 7

0.6 30 8 46 8 52 8

0.8 38 8 52 6 59 7

1.0 45 7 59 7 06 7 avg 7.4 sec/200cc = 27.0 cc/sec

stripixel stave 30 psi

--------------------------

l sec

run 1 run 2 run 3

----- ----- -----

0.0 05 05 09

0.2 11 6 11 6 -- 6

0.4 16 5 16 5 21 6

0.6 23 7 23 7 27 6

0.8 28 5 29 6 33 6

1.0 34 6 36 7 38 5 avg 5.93 sec/200cc = 33.7 cc/sec

stripixel stave 40 psi

--------------------------

l sec

run 1 run 2 run 3

----- ----- -----

0.0 41 44 51

0.2 47 6 49 5 55 4

0.4 51 4 55 4 01 4

0.6 56 5 59 4 05 4

0.8 01 5 04 5 10 6

1.0 06 5 10 6 16 4 avg 4.73 sec/200cc = 42.3 cc/sec

Mar 2010 HvH