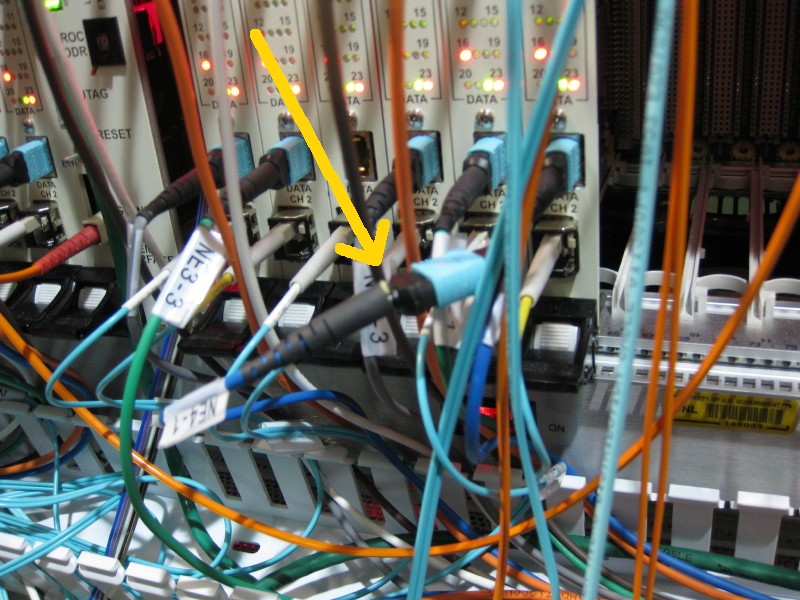

Several connectors broke. The force required to extract them is large, and there is very little

finger space. The connectors break where the rectangular body joins the round strain relief. Apparently

this is a weak point, and a design flaw of the connector imho. Note that among the connectors at the

FEM there are two that were apparently broken by the manufacturer and repaired with epoxy.

|

|

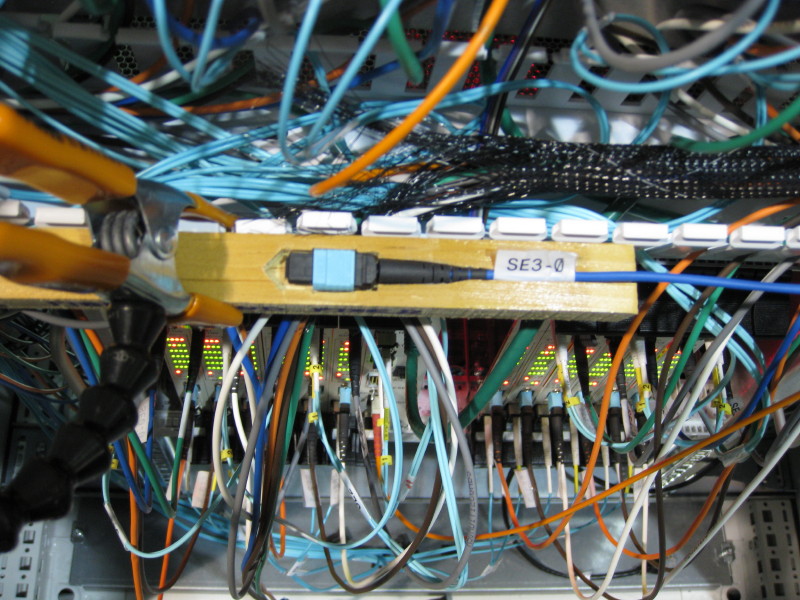

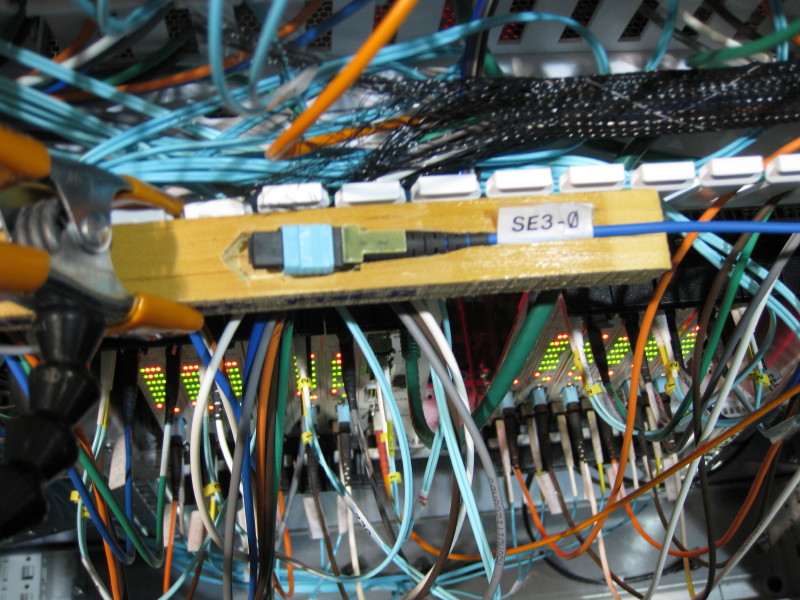

I made a jig to hold the connector and the cable. It is carved out to

hold them with a gentle squeeze fit.

|

|

Clamp the jig to the cable tray. Carefully extract the fiber and lay it in the jig

|

|

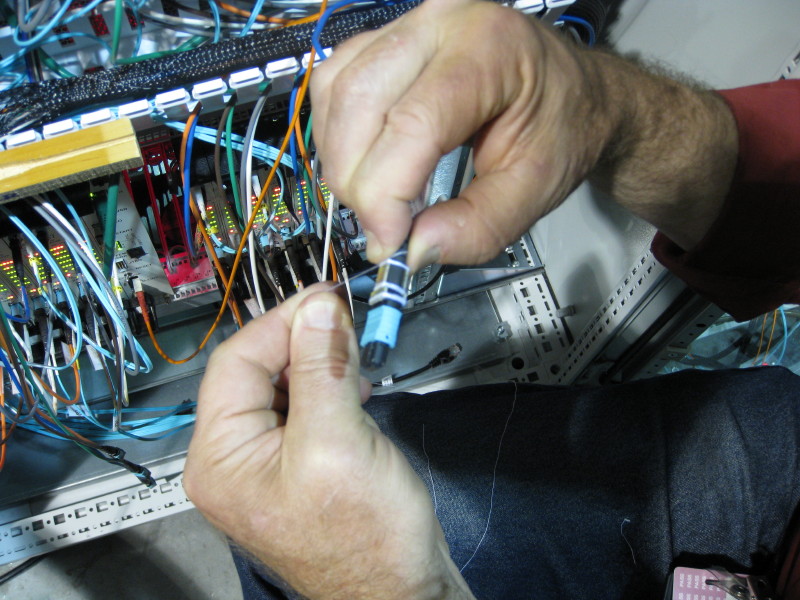

Pepare a T-shaped splint piece with 2-sided tape, and place it on the connector.

Gently press it down. Turn the cable over and place another splint on the other side.

The pieces are placed such that the blue sleeve can still be pulled back.

**Note added June 2013**: on one of the connectors I repaired in the IR (SE, bottom half), it

appears that the doublesided tape slipped. The repairs done in 2013 had the T's glued

with (Gorilla brand gel) superglue. Connectors repaired in 2013 have a narrow band of dark green tape

for identification.

The T is 9mm wide and 15mm tall. The top bar is 4mm, the post is 5mm wide, made out of thin G10

|

|

Wrap the assembly in 3 places: first on top of the T, then just under the top piece,

and last at the bottom of the T. Use cotton-polyester sewing thread and Elmers glue or

wood glue.

|

|

The thread is glued with elmers glue, once about halfway through each winding, and once at the end.

|

|

Finished connector, re-installed

|

|