| The transceivers are held in a cage which is soldered

to the board. There are 8 solder points (A),

4 are indicated. The top

cover of this cage clips over the top of this bottom U-shaper part

and is soldered only in 3 places in the back (B).

The walls of the cage have tongues which are folded over the back of the cage

after the top is put on. Here (D) they are bent back

when the top was lifted up and off.

The triangular hole (C) is where a latch on the

underside of the transceiver catches.

|

|

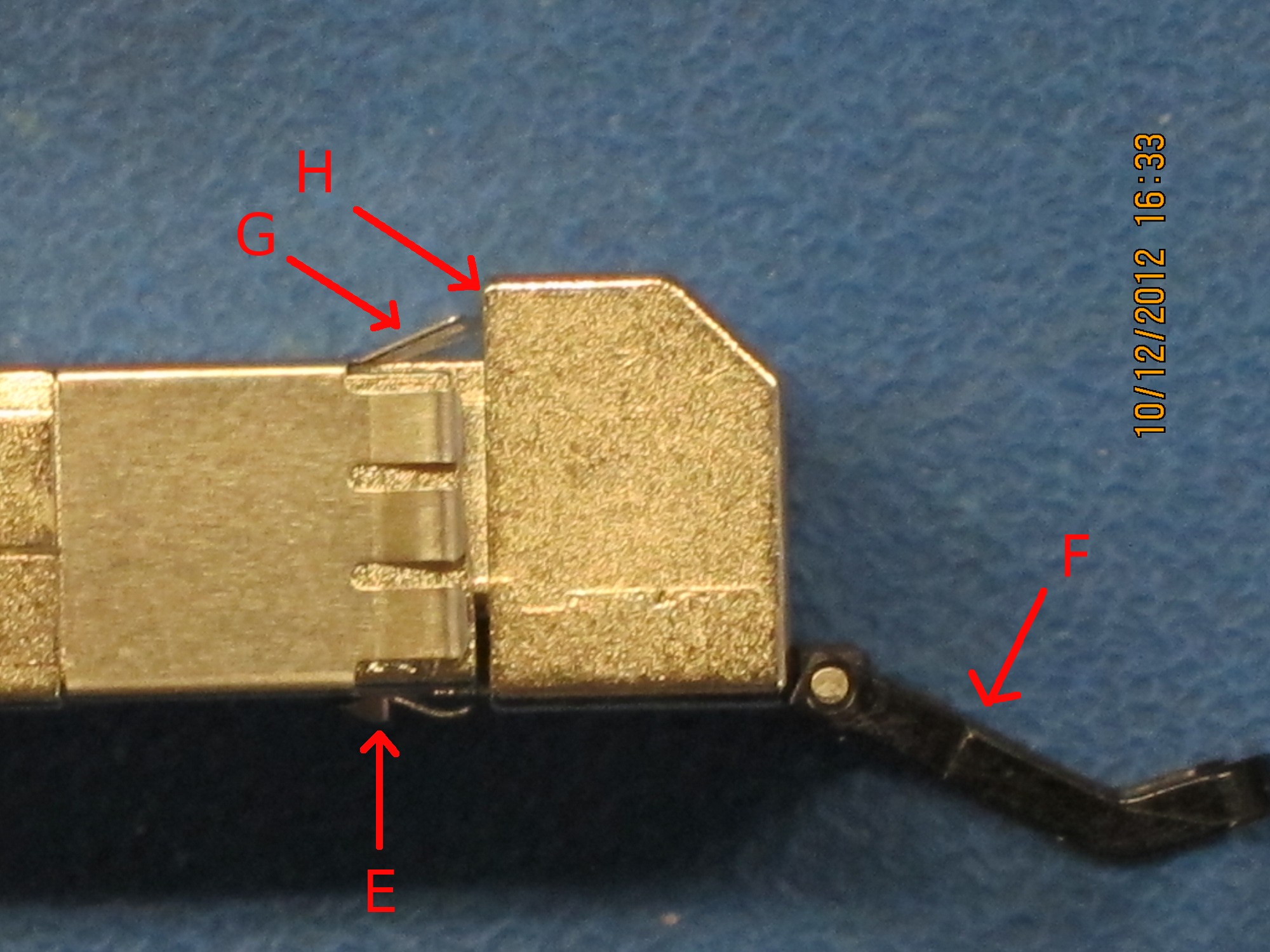

| This is the underside of the transceiver.

(E) is the latch that catches in triangular hole

(C). All the black plastic parts

(F) are part of the latch release mechanism.

|

|

| Side view of the transceiver. (E) is the

latch and (F) is the latch release.

The only (proper) way to get a transceiver out of a cage is by using

the latch release.

If you have managed to remove a transceiver without

exclusively pulling on the latch release (F),

you have lifted the transceiver

up high enough to get the latch (E) up and out

of hole (C).

(G) are flexible fins (also visible on the side here)

that ensure ground contact between the transceiver and the cage.

Normally, the top of the cage is lower than (H).

|

|

| This is the top cover of the cage, shown upside-down. Note the

sidewalls are not continuous front-to-back. This allows the taller front part

to bend up with almost no force.

On some of the cages, this front part is not secured, and the grounding fins

(G) can push it up.

|

|

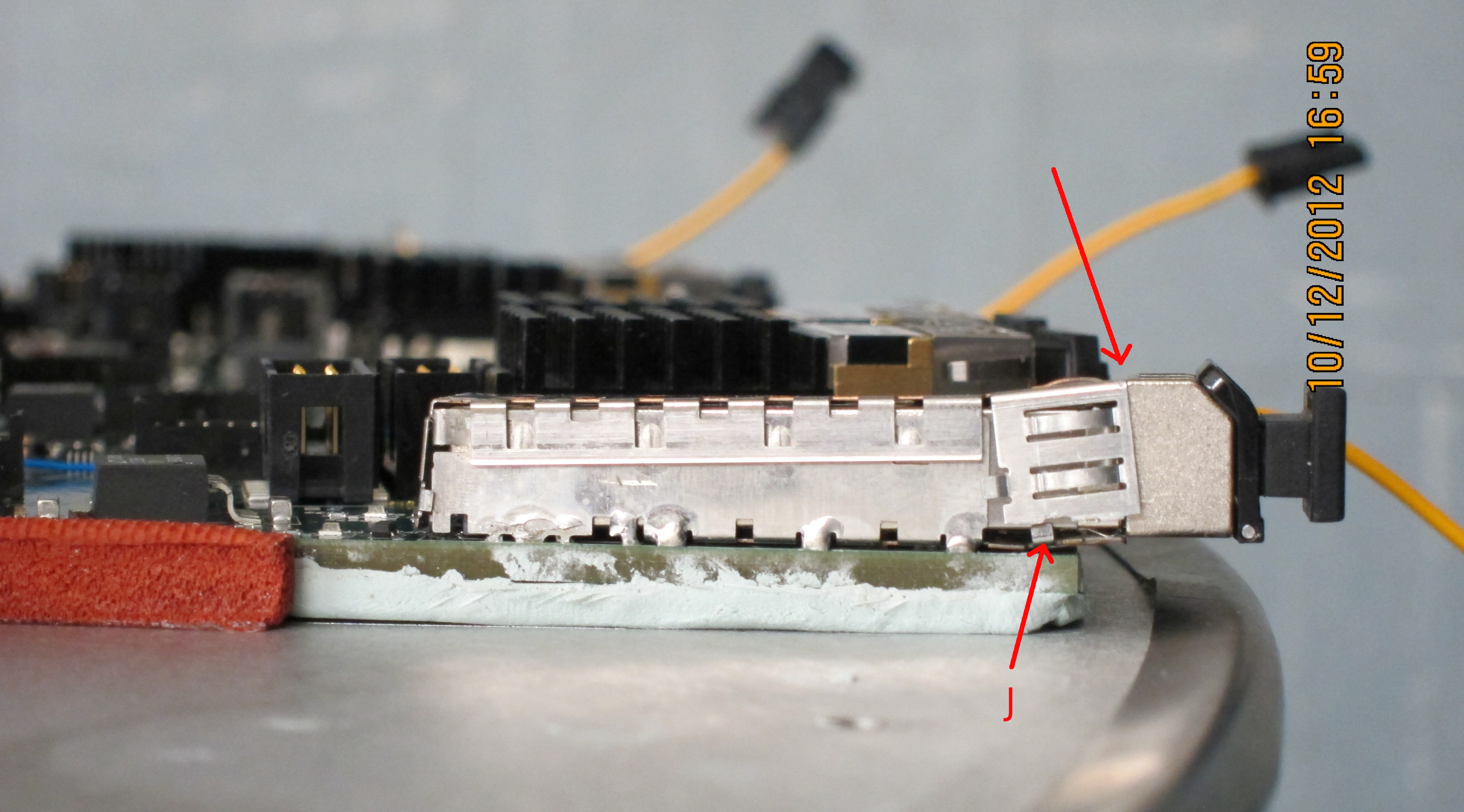

| This can be seen on this one. Note tab

(J). On some cages this is soldered to the bottom

part of the cage, so that the cage is solid and the tranceiver cannot be

lifted.

If the front part of the cage is lifted like this, the edge of the transceiver

is no longer stopped by the top edge of the cage, and can be pushed

in deeper than intended.

I believe this is what is happening when damage occurs.

|

|

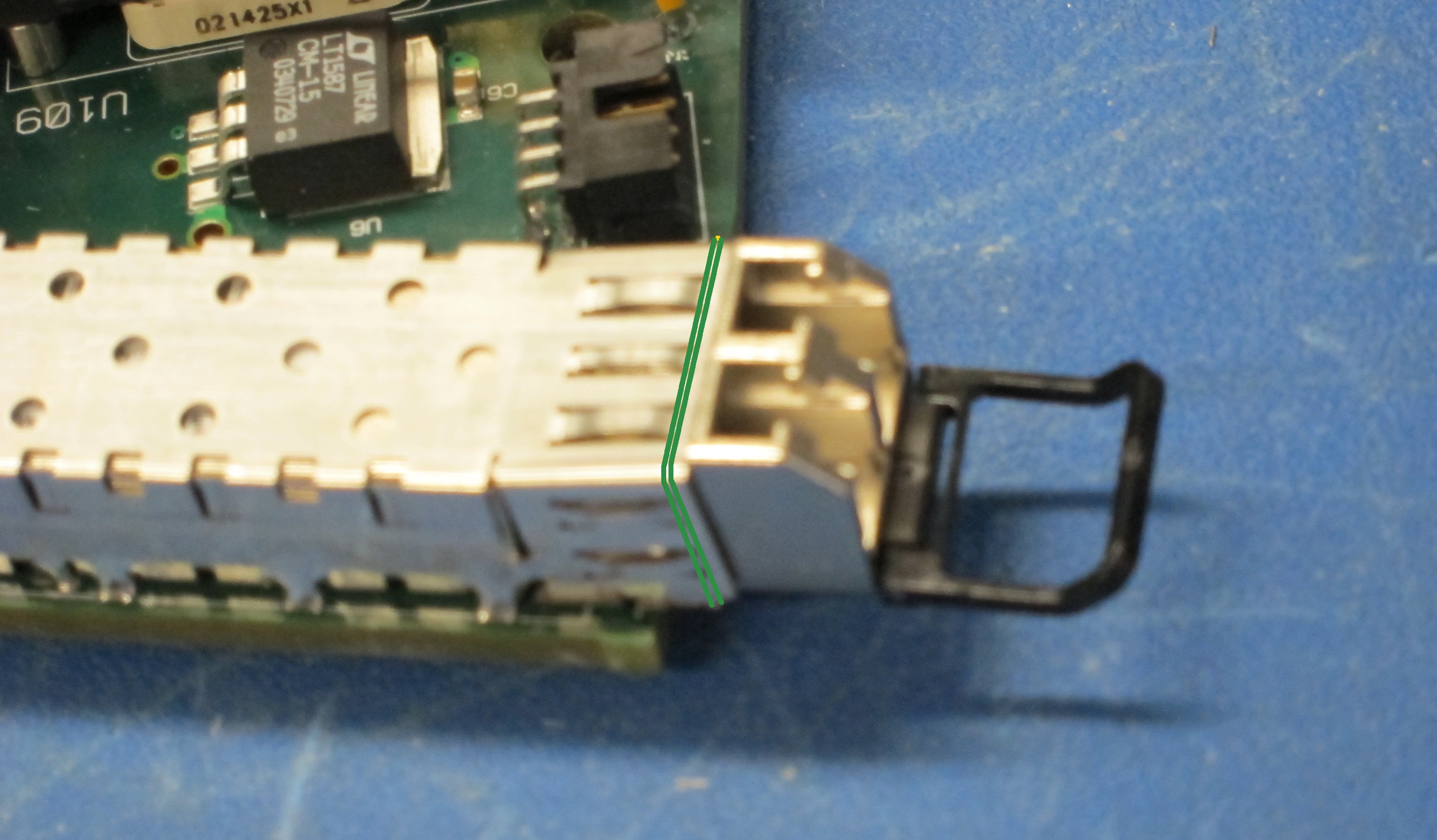

| One way to prevent this

is to tie down the front part of the cage in all cases where it is not

held down by the solder tab (J). We will wrap it with

cotton thread and secure this with white glue.

|

|

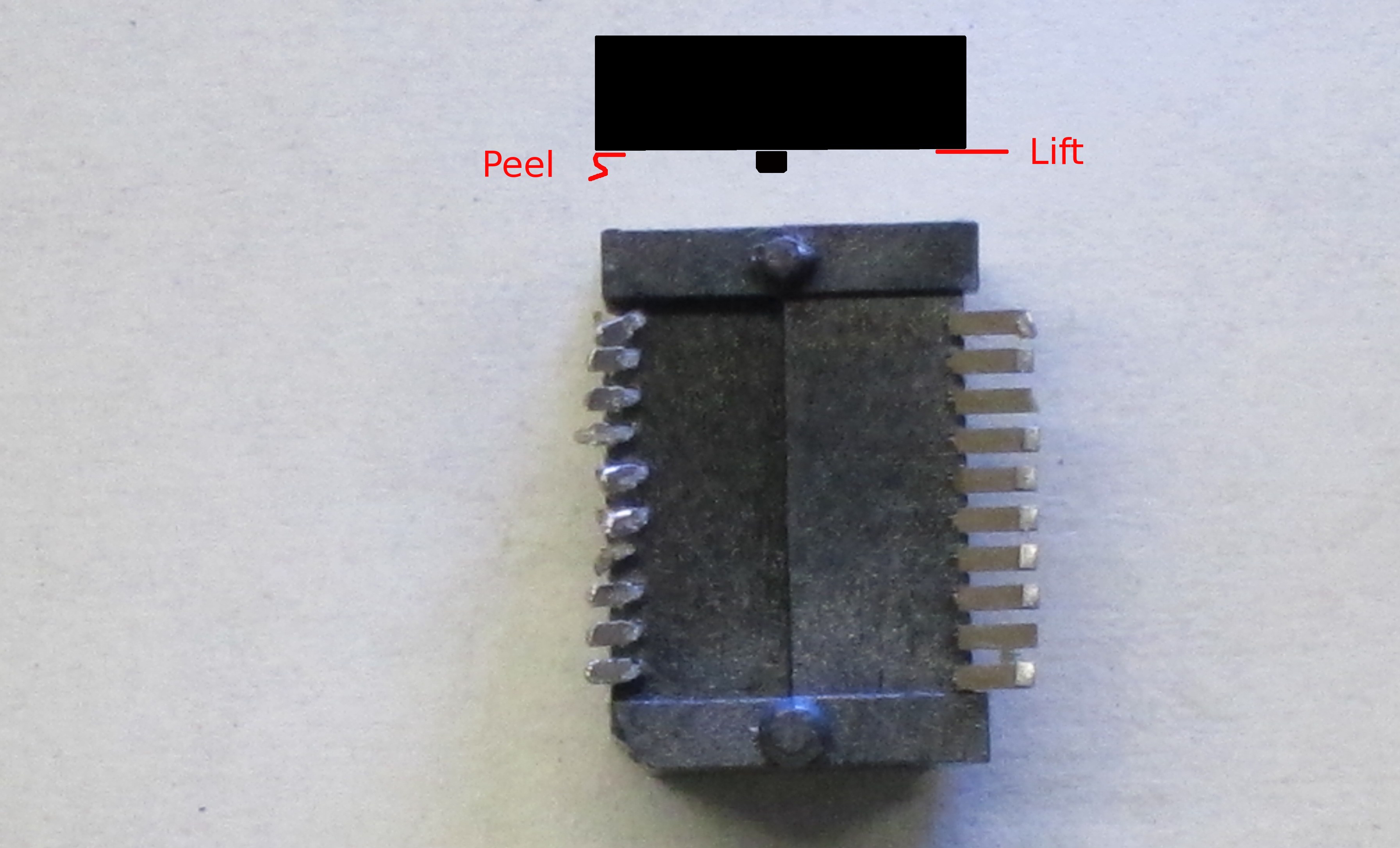

| Two alignment holes catch two pins on the underside of the

connector. Thus if a force is applied from the front, the connector cannot

slide back, but has to lift up first. So first the front pads rip off

vertically, and then the back pads bend and peel off.

|

|

| This can be seen here: The pads on the right are lifted clean off,

and the ones on the left are folded over as they peeled off.

|

|