| The gap-pad material that transfers the heat from the ROC to the

cooling plate is a clay-like substance that comes in 1/8" thick sheets.

On the back of the ROC are many small components, similar to these ones on

the back of a FEM board. You can press the material over these components,

but then

the surface that faces the cooling plate is no longer flat.

Shown here is a piece that has been pressed over the components and taken

off again and flipped over. You can see the indentations.

|

|

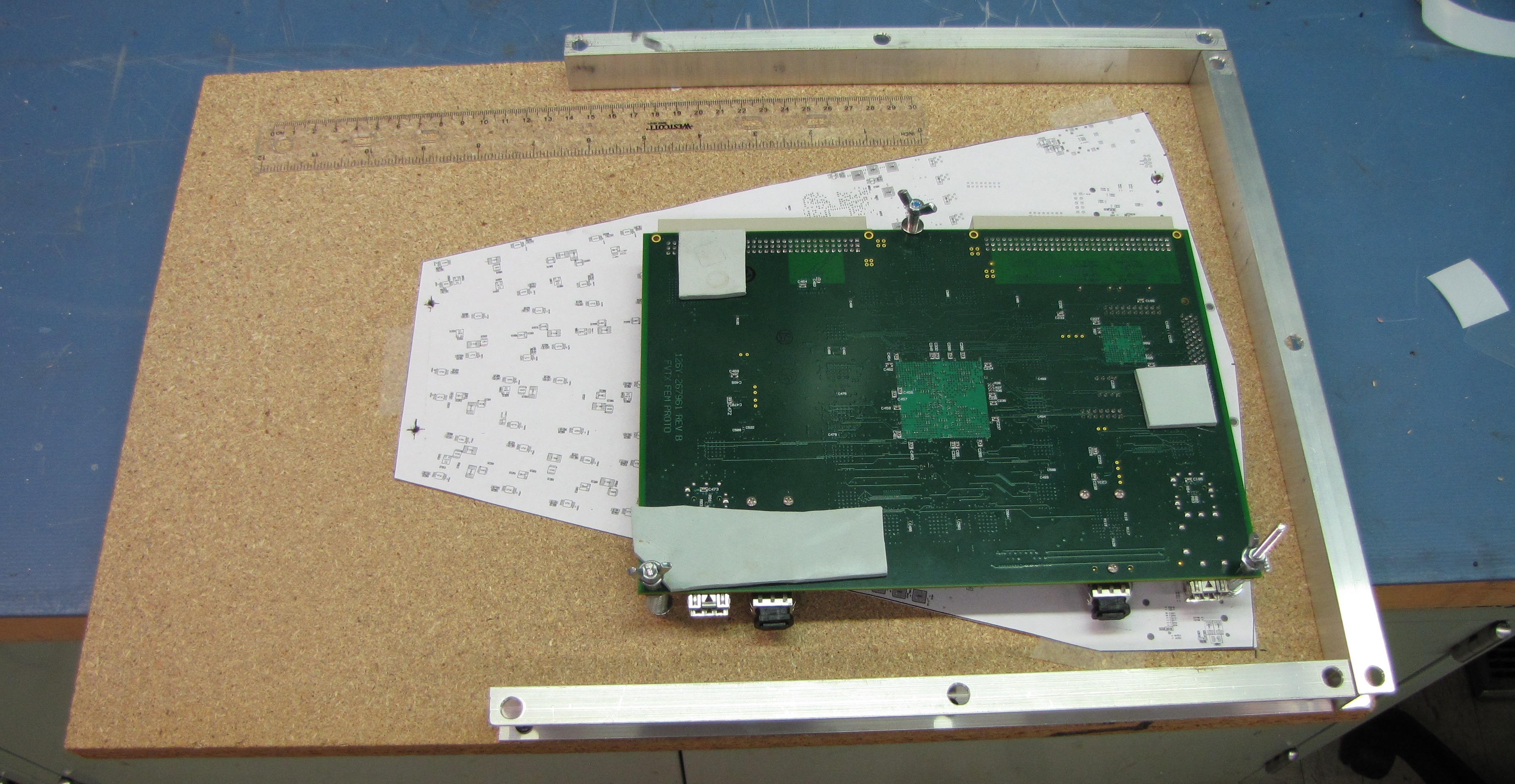

| The jig shown here allows you to level the gap-pad surface after

it has been pressed over the backside components.

It is a flat surface, with 3 sides of 1x0.5" Aluminum U-channel.

|

|

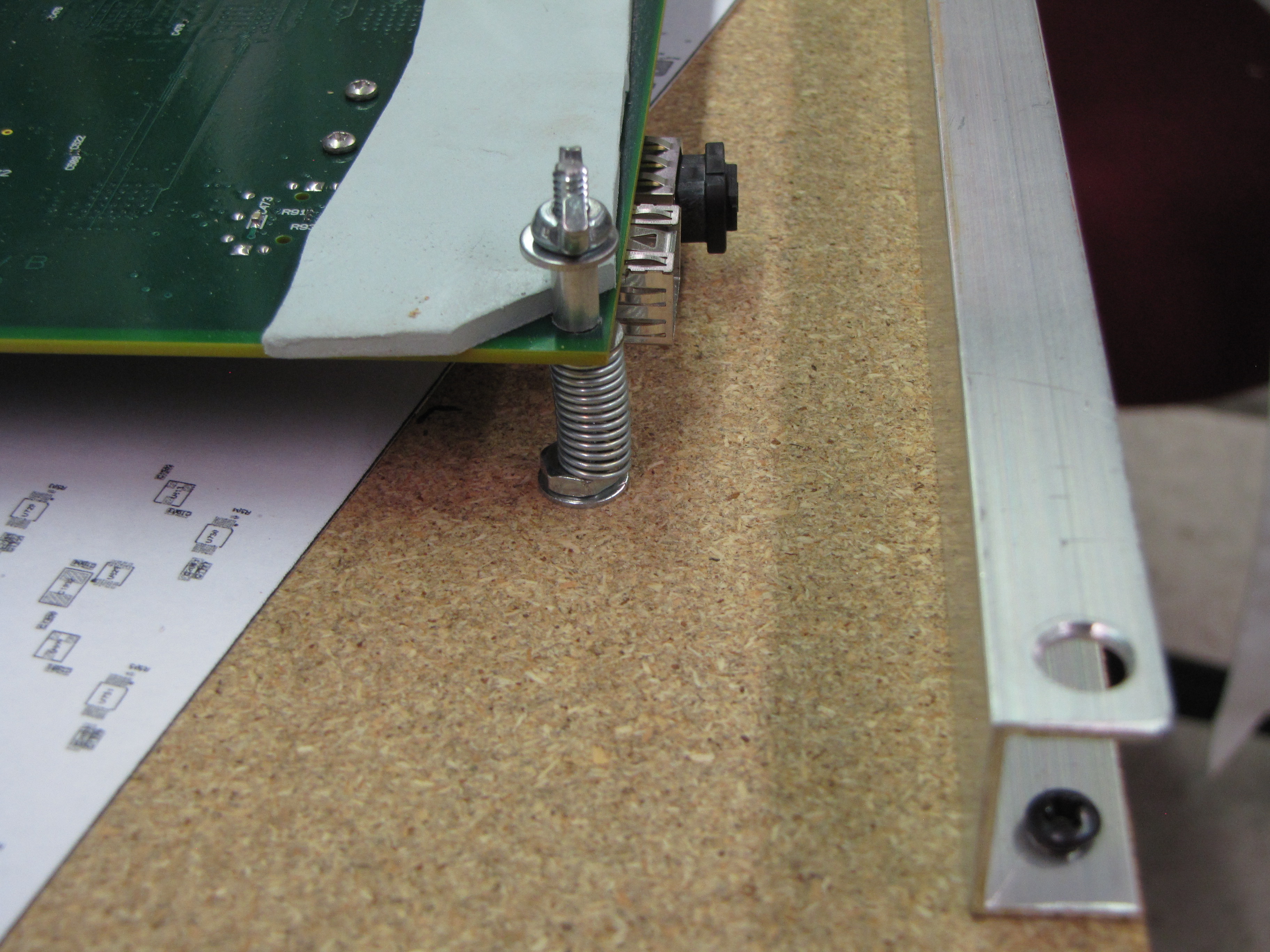

| The ROC board (or in this case a FEM board) is mounted on 6/32

threaded rods with a spring and

a wingnut, such that the height can be changed.

|

|

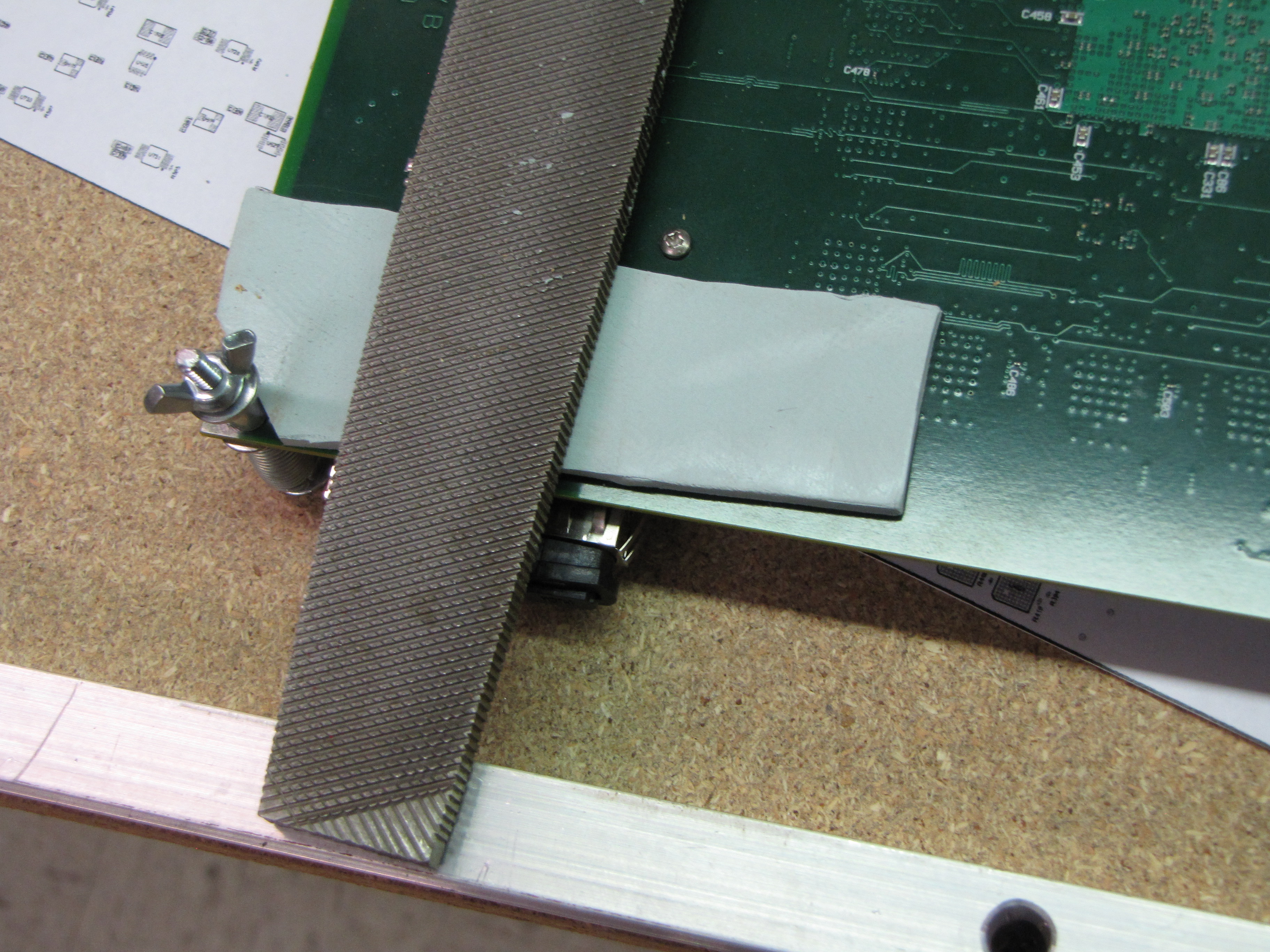

| Adjust the height all around such that a long file, laying on the

edges of the jig, just touches the bumps in the gap-pad material.

A few short strokes, applying no pressure other than the weight of the file,

will take off the high points of the gap-pad material. Carefully raise

the board and file until all the bumps are leveled.

|

|

| The material will clog the file quickly, so after every few strokes,

clean the file with a brass brush.

|

|