Blocks with grooves

| Turns out, the factory in Ukraine makes pre-assembled blocks of scintillator, with grooves for the wls fibers. We received 3 blocks, 21 cm long, consisting of 18 5×5mm scintillator bars, with 1.5 mm grooves milled in. Our blocks need to be 16 wide, but it was easy to split off 2 bars | |

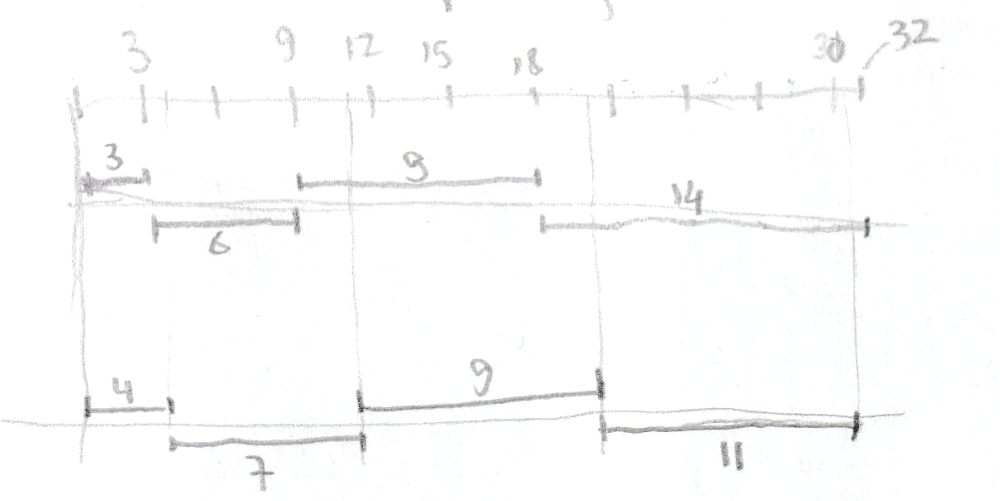

| If we cut the blocks (block 1 14 and 7 cm, block 2 9,9,3 cm, and block 3 11,6,4 cm we can make a 32 cm long, 2-layer test assembly. |

3 6 9 14

4 7 9 11

|

|

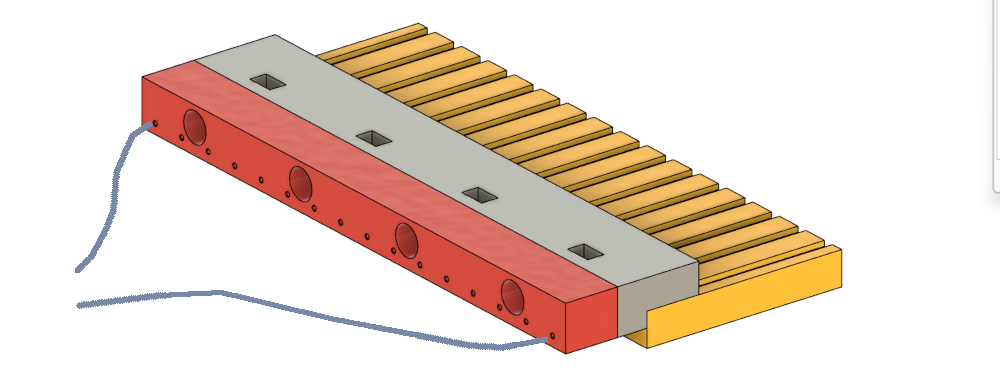

The yellow block has 16 3cm bars, with the grooves on top. The

grey coupler is glued to the scintillator block, and the wls fibers

continue to the grey-red interface, and are gued in the grey

coupler ad polished. The red block holds the 0.5 mm fibers, and

is attached to the grey coupler with 4 M2 screws. The M2 nuts

drop in the rectangular holes.

fiber_connector.stl (red)

|

|

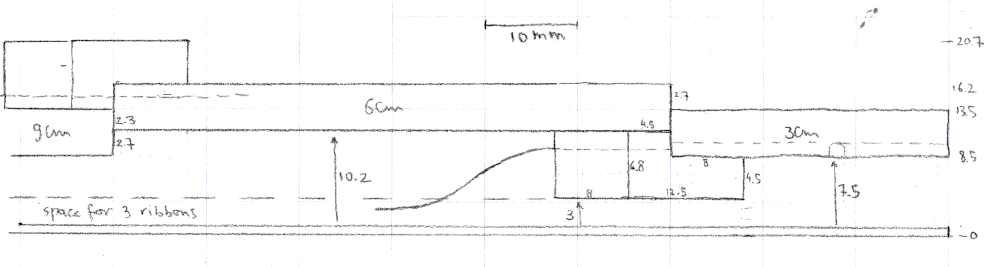

| The conectors drop 4.5mm below the scintillator blocks, and another 3mm is needed for the output ribbons. |

|

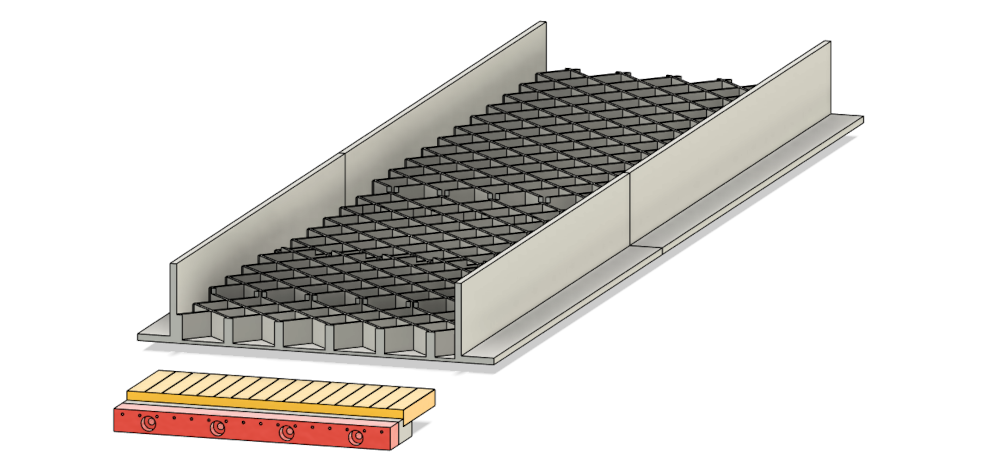

| To minimize mass of the supporting tray, the space can be made of honeycomb |

|

| I cut the blocks. The CO2 laser made bad cuts, so I used a miniature table saw with a 0.5mm kerf blade. Also not clean, as the plastic melts in the process, but these cuts do clean up nicely. Not recommended for production. | |