Silicon Strip Detector Design

The silicon barrels consist of 300 um thick AC-coupled polysilicon wafers, with

strips oriented perpendicular to the

beams. There are two sizes of strip detectors

fabricated from 4 in. silicon blanks. The inner (outer) barrels consist of

detector wafers which are 5.3 cm x 5.0 cm (5.3 cm x 8.0 cm). The strip pitch

on both detector sizes is 200 um, yielding 256 channels per wafer. The total

number of channels in the inner barrels is 18,432. The silicon detectors are

arranged in azimuthal sectors consisting of 12 detector wafers along the

beam (z) direction and six azimuthal sectors in the inner barrel, which

cover full azimuth and yield good vertex finding efficiency. To minimize

the radiation length of the MVD, and thus minimize conversions into the PHENIX

electron arms, the silicon detectors in the upper middle part of the outer

barrel have been removed. This leaves 10,240 channels in the outer barrel.

The large pitch, which is acceptable in our application as we do not require

precise track information from the silicon, greatly reduces the technical

challenges of bonding detector wafers to front-end electronics and limits

the channel count.

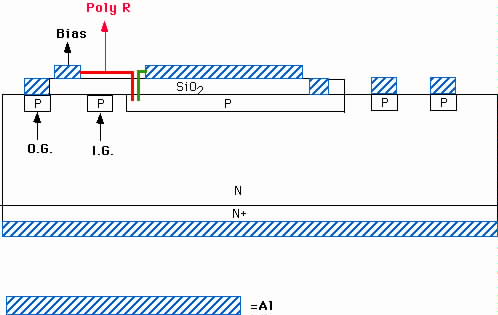

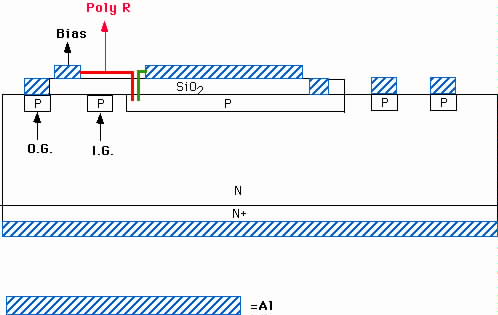

The biasing of the detector is through polysilicon resistor. The designed

values of the resistors are 10 +/- 5 MOhm. The bias resistor connects the

bias line and the p-semiconductor. There are two guard rings

on the detector. The inner guard ring, which is close to the strips, and the

outer guard ring, which is placed between the bias line and the cut-edge of

the detector. We use silicon dioxide as the environmental coating of the

detectors.

Figure Fig.2

Figure 2: The silicon strip detector of MVD.

Next: Silicon Pad Detector Design

Next: Silicon Pad Detector Design

Previous: Overview

Previous: Overview

Next: Silicon Pad Detector Design

Next: Silicon Pad Detector Design

Previous: Overview

Previous: Overview