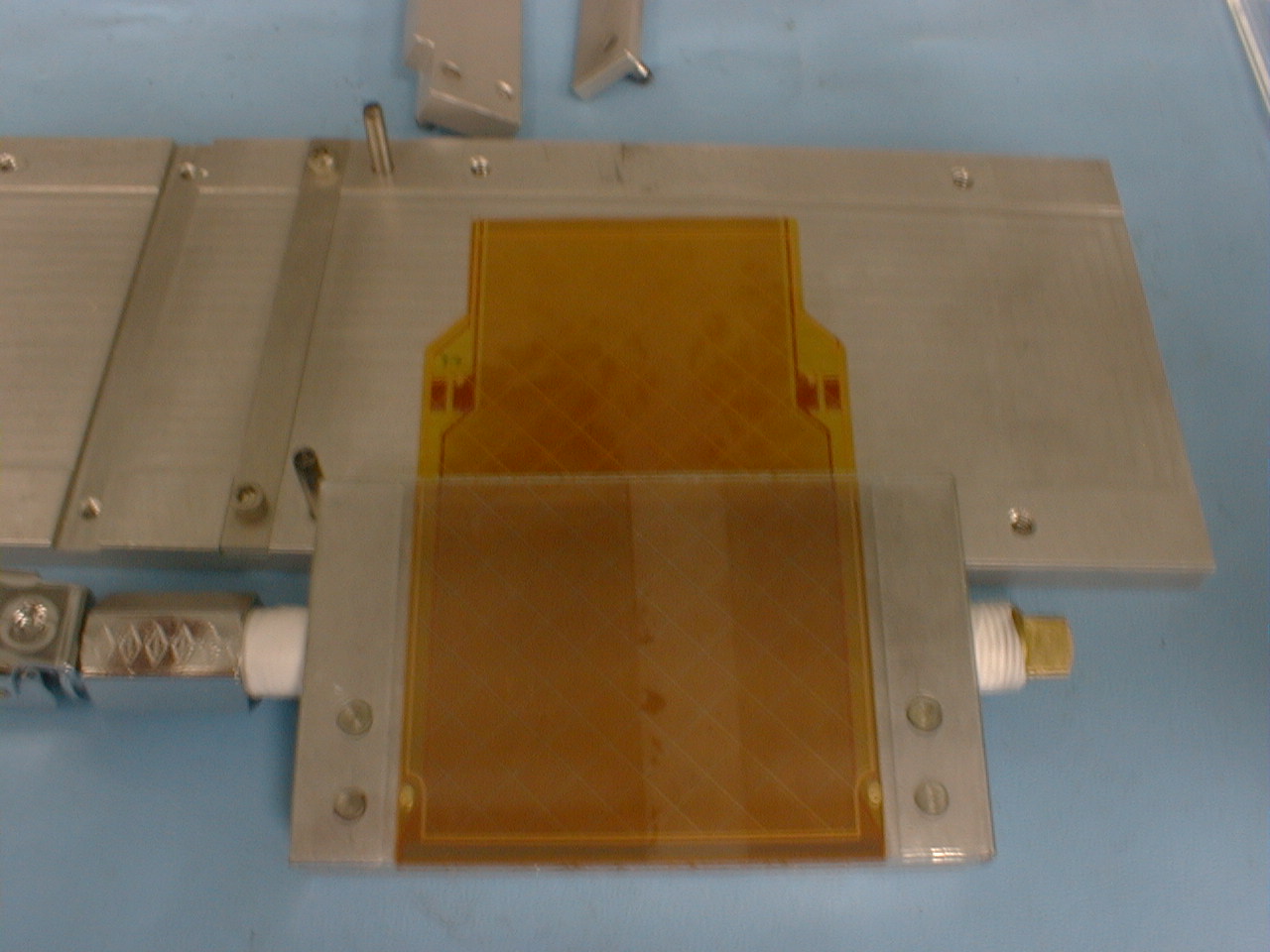

| Align the cable with the glass alignment fixture by moving the cable around until the ground grid on the alignment fixture is perfectly aligned with the ground grid on the cable. NOTE: some patience is required to get this alignment just right. When the cable is aligned perfectly, virtually none of the gold traces from the cable are visible--only the darker traces on the pickup fixture can be seen. The gluer must make sure that this alignment is good over the entire area of the glass alignment fixture. |  |

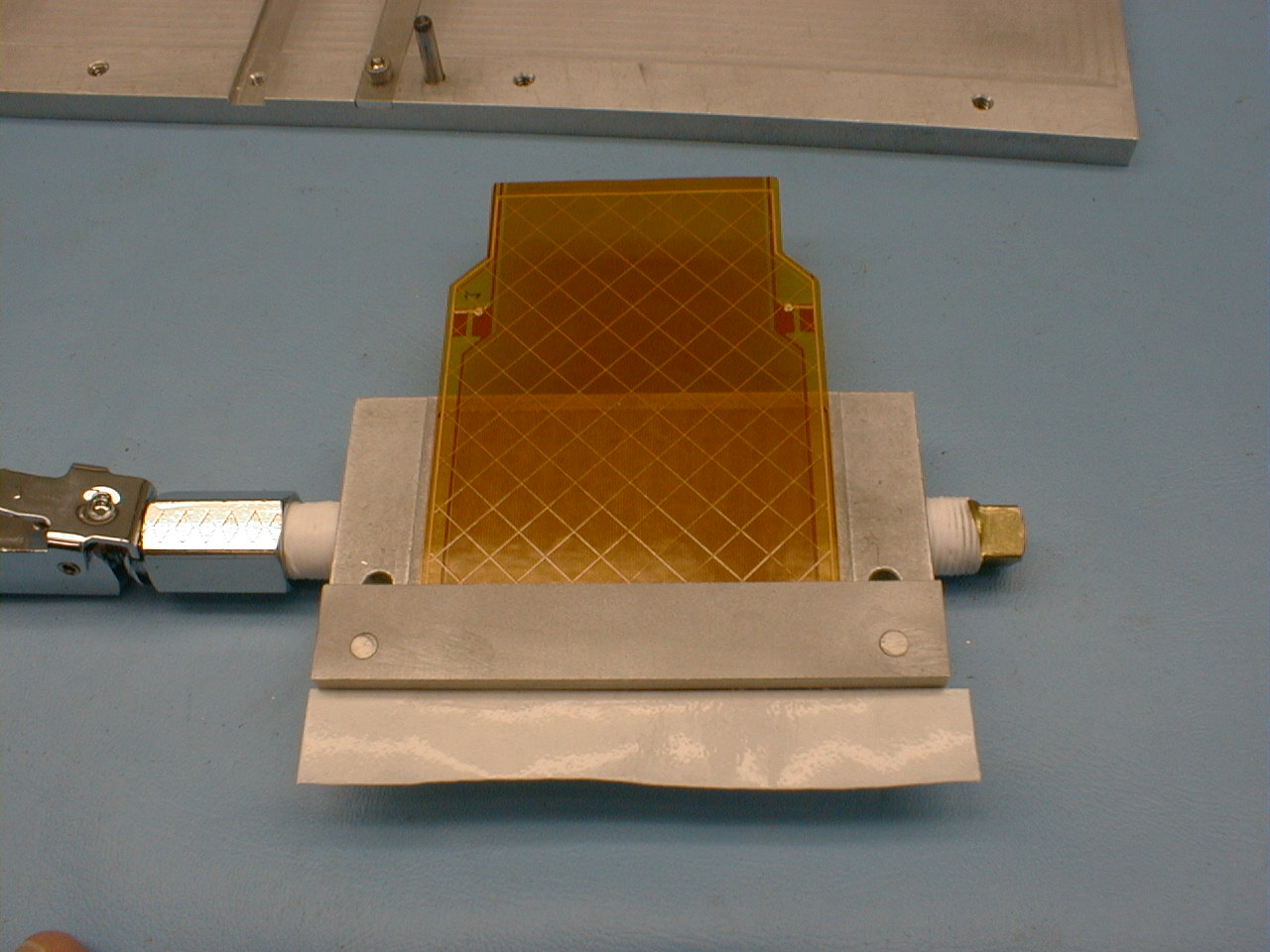

| Place the adhesive stop onto the pickup fixture, using the registration pins. Using the tweezers, apply the adhesive to the cable, with the protective sheet on the top and the adhesive side contacting the cable. Use the adhesive stop to locate the straight edge you cut in the previous step. When it is properly placed, run the rounded end of the tweezers over the protective sheet to ensure good contact to the cable. Remove the adhesive stop from the pickup fixture. |  |

| Place the adhesive mask on the pickup fixture, using the registration pins. With two 8-32 x 3/4" screws, tighten down the adhesive mask; this will allow for a pressure cure of the adhesive-cable bond. Allow the adhesive to pressure cure for 1/2 hour. |  |

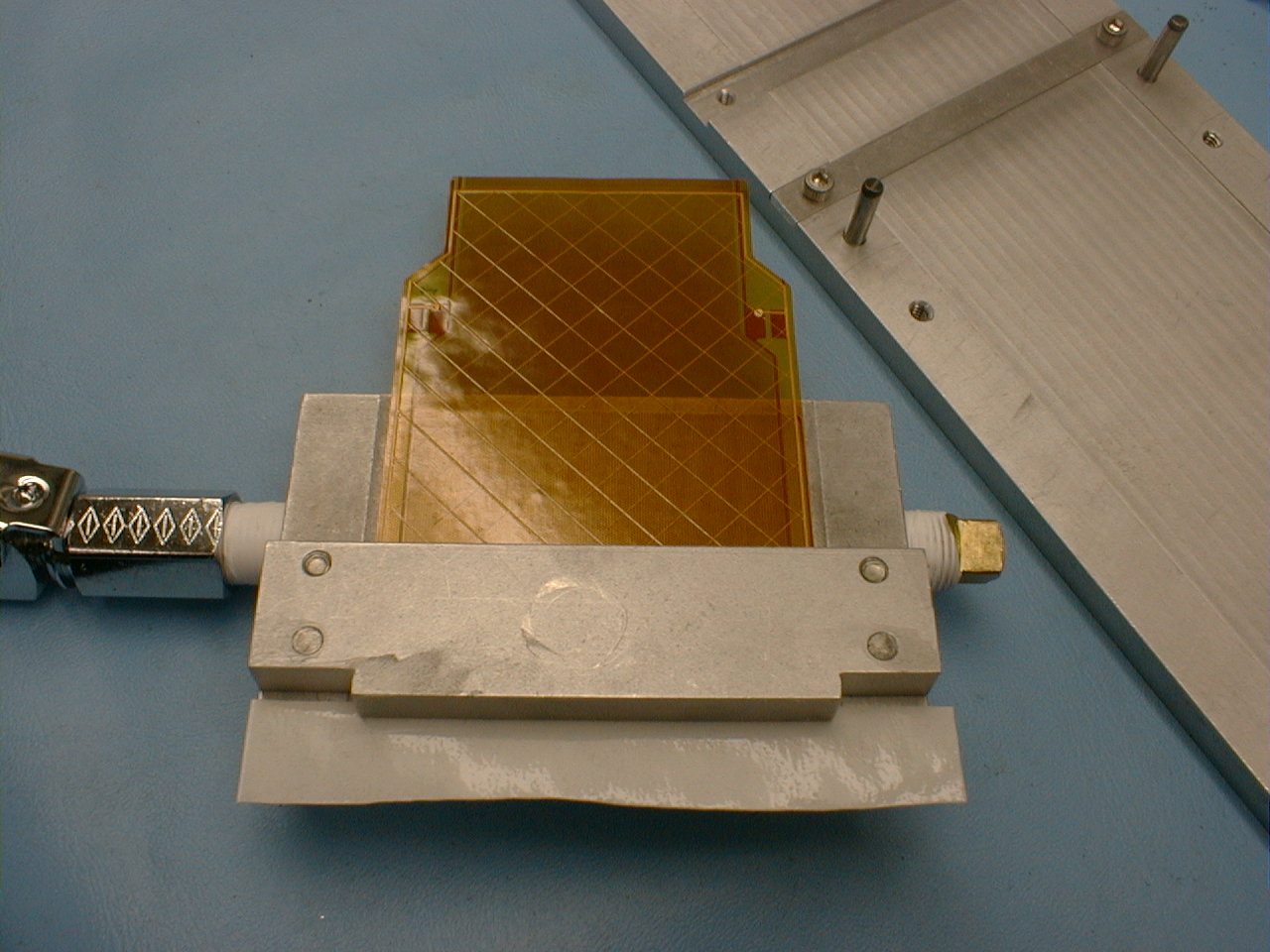

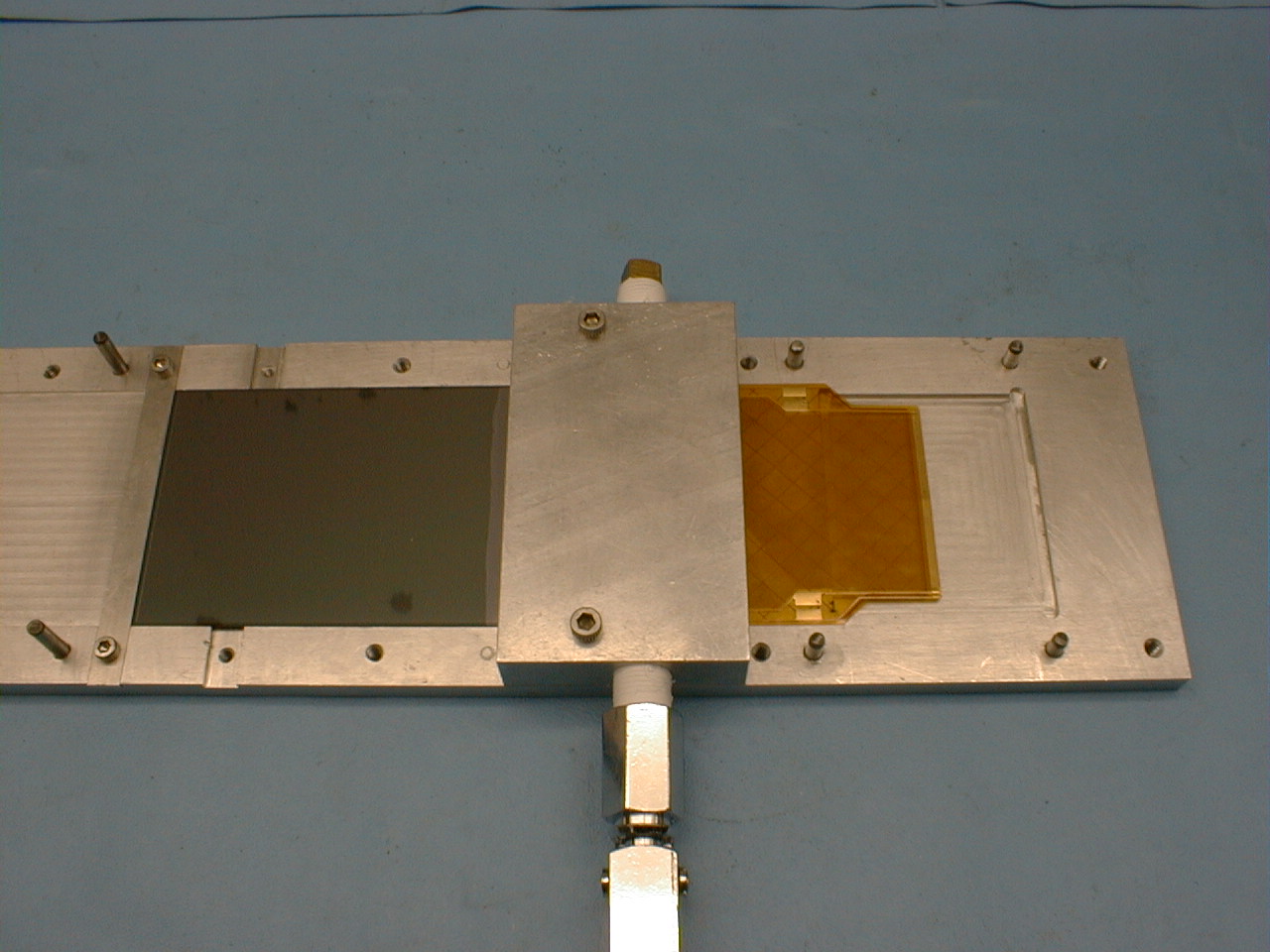

| Using the registration pins to align, place the pickup fixture and cable on the glue jig base plate, cable side down. This should allow the adhesive to contact the silicon detector. Using two 8-32 x 3/4" screws, tighten down the pickup fixture, which will allow for a pressure cure of the adhesive. After the fixture is screwed down, the vacuum can be disconnected. Allow the adhesive to pressure cure for a minimum of 2 hours. |  |